How gen AI can help amplify industrial efforts

Carefully curated AI, when integrated on a comprehensive industrial automation platform, will accelerate the way users develop, deploy and optimize manufacturing and processing operations.

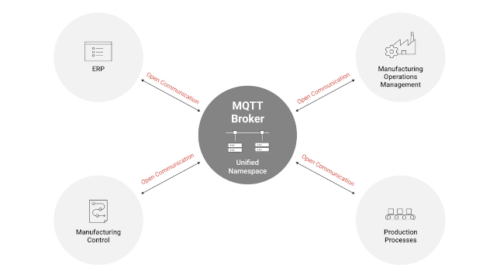

More answers about how to advance intelligent data sharing, analytics

Experts provide more answers about helping industrial communication advance intelligence data sharing and analytics for industrial control systems, after the Control Engineering “Control system integration” series of webcasts. The April 11 webcast is archived for a year.

Important advancements in VFD and motor control

Recent advancements in variable frequency drives have transformed these devices to enhance safety features and improve energy efficiency. See three VFD advanced control schemes.

How gen AI can help amplify industrial efforts

Carefully curated AI, when integrated on a comprehensive industrial automation platform, will accelerate the way users develop, deploy and optimize manufacturing and processing operations.

Automation mergers, acquisitions, capital markets analysis: April 2024

The Bundy Group reported 10 automation transactions in the month of April. Analysis on the acquisitions and reports are highlighted below.

More answers about how to advance intelligent data sharing, analytics

Experts provide more answers about helping industrial communication advance intelligence data sharing and analytics for industrial control systems, after the Control Engineering “Control system integration” series of webcasts. The April 11 webcast is archived for a year.

Blueprint makes quantum computers easier to program

MIT researchers have produced a conceptual model for a more user-friendly quantum computer for the future.