BP, Honeywell pen MAC agreement

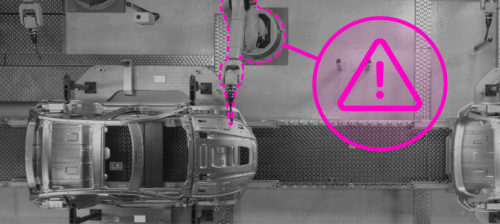

Honeywell announced a six-year agreement with BP Exploration to provide main automation contractor services at its new and existing facilities. Honeywell will help BP Exploration & Production accelerate production schedules and improve efficiency in these facilities by integrating all levels of plant operations and automating critical processes.

Honeywell announced a six-year agreement with BP Exploration to provide main automation contractor (MAC) services at its new and existing facilities. Honeywell will help BP Exploration & Production (E&P) accelerate production schedules and improve efficiency in these facilities by integrating all levels of plant operations and automating critical processes.

“Automation will be a key to streamlining operations and improving business performance as we move into the future,” said Tim Bass, director of procurement & supply chain management, projects & engineering. “Honeywell has the tools and experience to enable BP to implement its automation strategy, improving integration and the operating efficiency of our assets.”

Honeywell is said to provide front-end engineering development, early operator training and process simulation, advanced control modeling, process validation and advanced process control. This integrated approach is intended to provide common interfaces across production and business systems for increased safety and efficiency, higher plant availability, lower operating expenditures and reduced engineering.

“Automation means more than monitoring process variables and engaging valves,” said Jack Bolick, president of Honeywell Process Solutions. “When part of a larger, integrated approach, automation technology becomes a strategic investment that directly impacts a plant’s profit margin. Creating a smart plant leads to better business performance across the company.”

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.