Device asset management

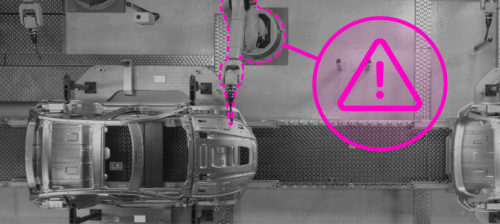

GE Intelligent Platforms is collaborating with Metso Corp. to resell its Metso FieldCare Device Asset Management solution, which provides a single tool with which to manage all the process devices in a system throughout the process plant lifecycle. FieldCare uses Web-enabled interfaces and real-time information from process control devices to optimize operations and reduce maintenance expenses.

GE Intelligent Platforms is collaborating with Metso Corp. to resell its Metso FieldCare Device Asset Management solution, which provides a single tool with which to manage all the process devices in a system throughout the process plant lifecycle. FieldCare uses Web-enabled interfaces and real-time information from process control devices to optimize operations and reduce maintenance expenses. The software is a condition monitoring solution that gives a quick overview of the operational status of all intelligent field equipment in the system to support predictive maintenance and can be used to plan regular maintenance activities. Functionality includes commissioning, device startup status, runtime baseline status for each device, shutdown preparation and service shutdown.

GE Intelligent Platforms www.ge-ip.com

Metso Corp. www.metso.com

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.