Thermal harvesting powers remote wellheads

Developments to watch from II-VI Marlow on the use of thermal harvesting techniques that can power remotely located wellheads in harsh environments.

As the oil and gas industry enters the age of big data and analytics, the wellhead of the future takes on a decidedly different look. A vast array of pressure, temperature, and flow sensors saturate the pipeline sending valuable data to a statistician many miles away. This happens as frequently as once every second, with sensors transmitting high volumes of data. The analyst can then make valuable decisions to maximize the flow-and the profitability-of the well.

Welcome to Siberia

Imagine a wellhead in extremely far north climates, such as Siberia or Canada’s Northern Territories. The problem of how to power the sensors must be solved for these regions. Is it feasible to run power lines to such locations? In most cases, this is an untenable expense. Alternatively, wireless sensors with batteries can be employed. However, a primary cell battery powering a sensor that transmits data every second will die much sooner than expected. A 10-year-rated battery can  quickly be reduced to two to four years of practical life, especially in extremely cold environments. Another option is to install solar panels, however, a mix of short winter days and heavy clouds or snow limits the effectiveness of this option as well.

quickly be reduced to two to four years of practical life, especially in extremely cold environments. Another option is to install solar panels, however, a mix of short winter days and heavy clouds or snow limits the effectiveness of this option as well.

The Seebeck effect

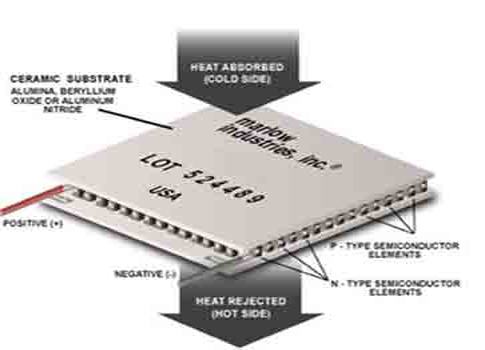

Thermal energy harvesting is a tangible remedy. In simple terms, this technology is the conversion of thermal energy into electrical energy using thermoelectric principles. This is not a new technology as thermoelectric modules (TEMs) have been used for more than 40 years, primarily as a method of heating or cooling. In traditional use, energy is applied to the leads of the small flat TEM, and it generates a temperature differential-a hot and cold side (see Figure 1). In the reverse mode, known as the Seebeck effect, if a temperature gradient is applied across the TEM, it produces a dc voltage and current through the output leads that can power an electrical load. In this power generation mode, the module is referred to as a  thermoelectric generator (TEG). The TEG power output is proportional to the temperature gradient across the device. So, cold weather and hot pipes stir up a fantastic recipe for generating power.

thermoelectric generator (TEG). The TEG power output is proportional to the temperature gradient across the device. So, cold weather and hot pipes stir up a fantastic recipe for generating power.

TEGs have several favorable features that make them great sources of energy for the oil and gas industry. First, they are engineered to last at least 20 years. Second, TEGs are highly scalable. If more energy is required, then connect more TEGs (in series to increase voltage and in parallel to increase current) until the desired power output is achieved. Finally, TEGs operate within a very wide temperature range. The cold side can handle -40 C while the hot side can withstand 230 C intermittently or 200C continuously.

Thermal energy harvesting

Marlow Industries, a subsidiary of II-VI Inc., has developed a technology composed of an aluminum collar, TEGs, and a heatsink (see Figure 2). The collar can be configured to accommodate a wide range of pipe diameters. Depending on pipe size, the collar can fit one to eight TEGs and heatsinks connected in series. The voltage output of the series TEGs is fed to a power circuit that consists of a dc-to-dc voltage converter, power conditioning, and energy storage via supercapacitors or lithium-ion (Li-ion) cells. When this device is attached to a 40 C pipe and ambient temperatures go as low as -40 C, each TEG can generate as much as 250 mW of power.

In many cases, thermal energy harvesting is in competition with other green energy harvesting technologies, such as solar and wind. In cold climates, however, thermal harvesting and solar are highly complementary. In extreme northern locations, summer days are long and often sunny allowing for the maximum output of solar energy. During this time of year, ambient temperatures are also high, meaning the temperature gradients across the TEGs are somewhat minimized. In the winter, however, the tables are flipped and thermal harvesting is far superior to solar. When the two technologies are combined, a consistent year-round power output can be delivered (see Figure 3, at top of the page).

The future is now

Early in 2015, a system like the one shown in Figure 4 was installed and came online. The total system met the goal of delivering more than 2 Watts of continuous power to a flowmeter running at 20% duty cycle. To meet the requirement for the  thermal harvesting portion, the thermal power unit uses 30 TEGs composed of two parallel strings of 15 TEGs in series. JSR Micro provided energy storage with its Li-ion capacitor (a type of supercapacitor). By early 2016, after a full year of power delivery data is collected, the system will be available to meet remote power needs of oil and gasfields in the extreme northern and southern hemispheres.

thermal harvesting portion, the thermal power unit uses 30 TEGs composed of two parallel strings of 15 TEGs in series. JSR Micro provided energy storage with its Li-ion capacitor (a type of supercapacitor). By early 2016, after a full year of power delivery data is collected, the system will be available to meet remote power needs of oil and gasfields in the extreme northern and southern hemispheres.

– Mike Deatherage is the Power Generation Global Marketing Manager at II-VI Marlow, thermoelectric technology provider. Mike has over 20 years of experience in various sales and marketing roles heavily focused on the application of power semiconductors. He holds a BSEE degree from The University of Texas at Austin. Edited by Eric R. Eissler, editor-in-chief, Oil & Gas Engineering, eeissler@cfemedia.com

Go Online

https://www.marlow.com/power-generators/evergen-power-strap.html

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.