Increase visibility, plant availability with predictive maintenance

To increase plant availability and reduce costs, use smart instruments for diagnostics and verification without process interruption, providing predictive maintenance for the process.

Learning Objectives

- Learn more about predictive maintenance for all industries and how it can work with process measurements.

- Understand the benefits of diagnostic technology and how it impacts a maintenance plan.

- How predictive maintenance and diagnostics technologies improve plant visibility and processes, reduce downtime and costs.

Is increasing plant availability and reducing costs important? Smart instruments guarantee diagnostics and verification without process interruption. Using predictive maintenance for process instrumentation can combine diagnostic, verification, and monitoring functions for process optimization. “Increase visibility and plant availability with predictive maintenance,” a May 4 webcast, archived for a year, explores how such technologies can improve processes.

Keith Riley, Endress + Hauser level and pressure national product marketing manager, said it’s important to:

- Learn more about predictive maintenance for all industries and how it can work within your plant

- Understand the benefits of diagnostic technology and how it impacts your maintenance plan

- How predictive maintenance technology improves plant visibility and processes

- Explore how diagnostic technology reduces process interruptions and costs.

Process measurement challenges

Issues facing process measurement applications include reliability, ease of use, availability, safety, predictive capabilities to optimize maintenance activities. Technology that monitors critical assets can help resolve these issues. Enabled devices can self-calibrate and report results, monitor and report if a temperature is too far off setpoint, send an alert if attention is needed or report which assets are working properly, Riley explained in the presentation.

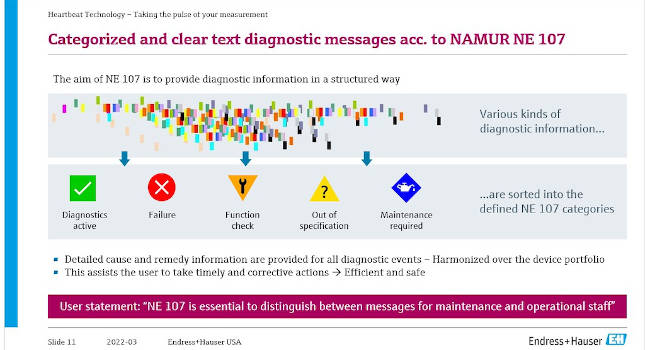

The Namur NE 107 diagnostic concept is a cornerstone of Endress+Hauser Heartbeat Diagnostics as it provides a high level of reliability and useful information for the user to keep operations efficient and safe, he said. It prescribes how to categorize diagnostic information for field devices in a uniform manner, assisting users to make timely and correct actions during a diagnostic event.

The Namur NE 107 diagnostic concept is a cornerstone of Endress+Hauser Heartbeat Diagnostics as it provides a high level of reliability and useful information for the user to keep operations efficient and safe. It prescribes how to categorize diagnostic information for field devices in a uniform manner, assisting users to take timely and correct actions in case of a diagnostic event. Courtesy: Endress+Hauser

Examples are provided about how diagnostic and monitoring technologies can be implemented for applications including flow, level, pressure, temperature and analysis and benefits they provide.

Endress+Hauser webcast information edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, mhoske@cfemedia.com.

KEYWORDS: Industrial asset management, predictive maintenance, diagnostics

CONSIDER THIS

How can you increase process reliability and quality while reducing costs related to asset management?

ONLINE

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.