Suzanne Gill

Articles

Why is trust becoming such a big issue?

The latest thinking of automation vendors, relating to cybersecurity in the OT environment, indicates trust is an issue.

Digital twin technology benefits for control engineers

Control engineers working in industrial environments should be looking at adopting digital twin technology to model their processes.

AI benefits for industrial manufacturing environments

Management and interrogation of data for improved decision-making sits right at the heart of any digital transformation and it relies on server technology to deliver real-time data and artificial intelligence (AI) can help.

Overcoming SCADA integration cybersecurity challenges

There are several steps that need to be taken to overcome cybersecurity challenges when integrating a new SCADA solution.

How digitalization, digital transformation strategies are evolving

The goals of industrial digitalization have changed and there are many potential disruptions in the digitalization journey for manufacturers.

Utilizing controllers successfully in smart manufacturing, digital transformation

Machines, particularly PLCs and PACs, have a key role to play in enabling smart manufacturing and more interconnected factories.

The human role in cybersecurity cannot be underestimated

When it comes to cybersecurity, the role of the human cannot be overemphasized and it is vital all employees have a good understanding of their role.

Turning smart devices into valuable IIoT devices

There are several ways to make a field device or a sensor "smart" and turning them into valuable IIoT devices.

How TSN benefits industrial applications

Time-sensitive networking (TSN) can offer many benefits in industrial applications once the barriers to its adoption are overcome.

How sustainability can be a driver for digitalization

Sustainability is becoming an important driver for change in the industrial sector as companies look to improve profits while being safe and environmentally-conscious.

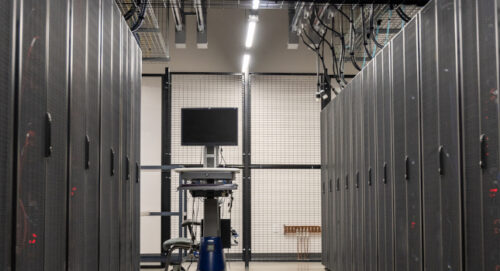

Edge computing use cases, success stories

The adoption of edge computing at all levels within a system architecture means that a diverse range of hardware and software solutions are required.

How collaborative robots’ flexibility benefits manufacturers

Collaborative robots (cobots) are growing in industrial manufacturing applications because of their flexibility and their ability to work alongside humans whereas traditional robots cannot.

Next steps for digital transformation for manufacturers

With many industrial organizations now having taken their first digitalization steps, there are potential disruptions for manufacturers with their digital transformation journeys.

The driving force behind Industry 4.0 success

Smart sensors play a key role in helping manufacturers achieve Industry 4.0 goals.

AI used to control process manufacturing operations

A project in Japan used artificial intelligence (AI) to autonomously control a chemical plant for 35 consecutive days.

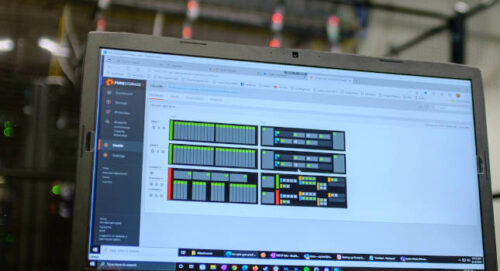

IT, OT convergence enabling digital manufacturing transformation

Information technology (IT) and operational technology (OT) convergence is enabling a digital manufacturing transformation.

Single-pair Ethernet benefits for manufacturers

Single-pair ethernet (SPE) has been gaining attention in recent years and has many potential applications and advantages for manufacturers.

Moving toward edge computing adoption

For the control engineer, it's worth asking what the benefits are from moving intelligence to the edge and how they can achieve success in brownfield plants.

AIoT improves transparency, quality for manufacturers

The speed of adoption and the potential benefits of combined artificial Intelligence (AI) and Internet of Things (IoT) technologies in the industrial sector could lead to many positive benefits.

Achieving net zero carbon emissions with SCADA

Supervisory control and data acquisition (SCADA) software can play a key role in helping industrial organizations on their journey to net zero carbon emissions.

Accelerating digital twin technology adoption

Digital twin technology is evolving manufacturing plants and many companies are taking advantage of its benefits.

IT/OT convergence advice, best practices for manufacturers

Cybersecurity experts offer advice and best practices on information technology/operational technology (IT/OT) convergence and how manufacturers can prepare themselves for challenges.

Keeping OT environments cybersecure

What can engineers do to protect their processes and plants from cyberattack? Consider these best practices from cybersecurity and manufacturing experts.

Digitalization crucial for food manufacturing processes

Smart and proactive digital solutions can help support ongoing operations even through disruptive global events like the COVID-19 pandemic.

How collaborative robots’ role is growing on the plant floor

A key factor behind the growth in collaborative robot deployment is the ready availability of simpler and more cost-effective systems comprising standard hardware, tooling and ancillary components

Building resilience with robotics

Will the COVID-19 pandemic accelerate the speed adoption of robotic and automation across the industrial sector? There are many factors at play.

Getting on board with AI technology

It is becoming a reality that artificial intelligence (AI) are starting to change the traditional role of the control engineer. There are some benefits, but there also potential barriers to its adoption in the industrial environment.

Putting pressure on productivity for oil and gas applications

Carefully selected measurement instrumentation and a suitable inventory management system help avoid the health and safety risks associated with the necessary chemical injections in the oil and gas industry and can also help reduce costs.

Manufacturers need to prepare for cyber threats

While industry sectors are starting to automate their processes to help increase productivity and efficiency and this requires greater connectivity, which also can expose systems to attack.

Simplifying digital migration

There are many ways industrial communications are supporting and simplifying the digital migration process.

Addressing digital migration challenges

As industry starts to engage in digital transformation programs, engineers tasked with managing this change are running into several challenges.

Robots need to understand and think more

Robots, according to a paper from the University of Birmingham, will need to think in the right context as economies embrace automation, connectivity and digitization and as levels of human-robot interaction increase.

Putting safety first with collaborative robots

While collaborative robots are starting to be accepted within the manufacturing sector, safety is still a concern for many. Learn how several companies are working to address the safety issue and address misconceptions.

Industrial cybersecurity strategies need a new approach

While Industrie 4.0 and the Industrial Internet of Things (IIoT) is enhancing the digital and connectivity capabilities of industrial control systems (ICSs) it has also opened the floodgates to serious cybersecurity risks.

Automation software can improve plant flexibility

The automotive industry, which can be rigid and inflexible, can improve production and meet increased demand for customization with automation software.

Making things work as part of the IIoT

Sensors are on the front line of the data gathering process, which is vital for the Industrial Internet of Things (IIoT).

Retrofitting Industrie 4.0 for digital control systems

Ypsomed, a medical technology company, was able to retrofit Industrie 4.0 digital control systems onto its legacy plastic injection molding machines.

Managing industrial Ethernet switches

While traditional industrial networks are using Ethernet switches to prepare for the Industrial Internet of Things (IIoT) applications, there is a place for unmanaged switches, though they come with some risks.

Easier automation helps food production

Control Engineering International: What will future food manufacturing environments look like? Suzanne Gill, Control Engineering Europe, spoke to some key industry vendors to get insights about the future of food production. As the need for skilled labor increases, and regulations require track and trace records, advanced automation is getting easier to apply and use.

Magnetic levitation for PCB production

A combination of linear drives and magnetic levitation can be used to alleviate particulate contamination on printed circuit boards’ (PCB) production lines, explained Paul Streatfield of Bosch Rexroth, for Control Engineering Europe.

Meeting the requirements of Industry 4.0

Achieving smarter factories and reaching the goals set by the Industry 4.0 initiative can be helped by what CC-Link IE has to offer, as Control Engineering Europe editor-in-chief Suzanne Gill explains.

FDI and FDT: Working together for easier integration

As field devices become more and more intelligent, they can provide huge amounts of data, which, if turned into useful information, can offer big benefits. The creation of a standardized way to describe automation components and to communicate with them is therefore becoming increasingly important. FDI (field device integration) could possibly be a new standard in the industry.

Industry first: In-line flowmeter employs SAW-based technology

Bürkert is preparing to launch its new FloWave series of in-line flowmeters which, uniquely in flow applications, employ surface acoustic wave (SAW) technology. The company presented for the first time at Hannover Fair this year, Suzanne Gill reports.

Three wishes for an easier life with HART

At Hannover Messe 2013, Michael Pelz, head of process optimization and automation for Clariant Pigments Business Unit, spoke about his experiences with HART technology, while expressing his hopes for future developments to make the technology even easier to work with.

HART Communication adapts for the Internet world

A closer look at the benefits offered by HART-IP, which is the latest enhancement to the HART Protocol Specification

Instrumentation software offers device setpoint confidence, remote monitoring

Control Engineering International: Challenged with device documentation? A chemical manufacturer in Switzerland uses a software application to ensure accurate remote monitoring of field devices and remote monitoring, among other benefits, according to a Control Engineering Europe report.

DART and the promise of high power with intrinsic safety

Dynamic Arc Recognition and Termination (DART) technology is set to become an IEC standard after first hitting the headlines in 2008, with the promise of making higher power possible in hazardous areas. Suzanne Gill, Control Engineering Europe, explains the latest.

Updated alarm management guidelines

Control Engineering International: Alarm systems design, management, and procurement advice is available in the third edition guide from Engineering Equipment and Materials Users' Association (EEMUA), reports Suzanne Gill from Control Engineering Europe.

Taking measurement to a new level

New level sensing technology is said to offer a cost-effective way to accurately measure liquid levels without the need for calibration across a large number of fluids. Suzanne Gill, Control Engineering Europe, spoke to the principal engineer involved in its development by Cambridge Consultants.

HART – the next 20 years…

Control Engineering Europe talked with Ted Masters, president and CEO at HART Communication Foundation, offers views on how and why the HART protocol will stay relevant for the next 20 years.

Industry prepares for the next industrial revolution

Automation companies share views on the fourth industrial revolution, Industry 4.0, according to Control Engineering Europe.

Information integration for machines ties PLCs with mobile devices, higher-level systems

Control Engineering Europe: At Hannover Fair 2013, work on integration of PLC and information technology was recognized. Bosch Rexroth, won the 2013 Hermes Award at Hannover Messe, for its Open Core Engineering project. Award-winning integration solution puts machinery manufacturers in the driving seat, according to Control Engineering Europe.

Network organization pushes industrial Ethernet for process automation, machine integration

Control Engineering Europe: At Hannover Fair 2013, ODVA continues on the path of collaboration and partnership with Cisco, Endress+Hauser, Rockwell Automation, Schneider Electric, and others to accelerate adoption of industrial Ethernet in process automation. A machine information integration initiative was discussed.

HART: benefits for today and into the future

Suzanne Gill finds out what the HART community believes are the real benefits of HART communication and how it can help to meet the industry needs of today and into the future.

Smart futuristic ideas to manage process control challenges

Emerging technologies, including safety, visualization, mobile computing, and alarm management, among others, were covered at the Yokogawa 2012 European User Conference, where the company showcased its R&D efforts, according to Suzanne Gill, Control Engineering Europe.

How advanced technologies can meet process engineering challenges ahead

Challenges facing the process engineering sector and technologies can help, explained Dr. David Brown, chief executive of the Institution of Chemical Engineers (IChemE) at the 2012 Yokogawa User Conference. The European Commission expects advanced engineering to help, via the Horizon 2020 Initiative.

FDT2 goes public with better graphics, interoperability, PLC integration

Control Engineering International: Enhancements to FDT standard in version 2.0 include better graphical presentation, separation of GUI and business logic, Common Components tested for interoperability, and better PLC integration, said the FDT Group AISBL. First products became available in June.

Working toward an intelligent energy management solution

Control Engineering International: Suzanne Gill, Control Engineering Europe, spoke to Dr. Richard Bateman from the Advanced Manufacturing & Enterprise Engineering (AMEE) group at Brunel University to find out about the EuroEnergest project whose ultimate aim is reducing energy usage in the automotive industry.

Exploring robotics for the factory of the future

Control Engineering Europe’s Suzanne Gill reports on a European Commission co-funded project that is testing the idea that industrial robot technology could provide a good base for machining, being both flexible and cost-efficient. Researchers are engineering robots to perform CNC operations.

Global Perspectives: European efficiency labels for electric motors

Euro motor efficiency: Control Engineering Europe’s Suzanne Gill reports on the effects of June 2011 European motor regulations, relating to the energy efficiency rating of induction motors. Link to more information, including U.S. comparison.