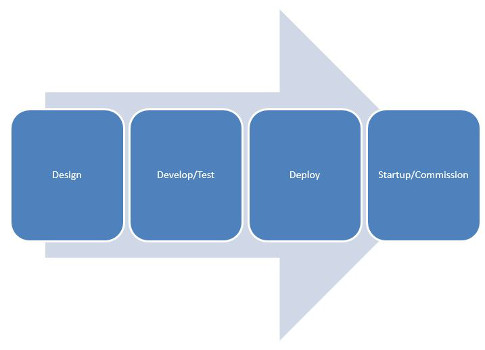

Project deployment is a critical time in the life cycle of a process automation project. It follows design/development and precedes startup/commissioning. During this project stage, the process automation team ‘deploys’ the applications they have written and tested with the customers into the plant’s systems and hardware.

Because startup and commissioning efforts cannot begin until completion of deployment, it can be a high-pressure time for the project team. The compressed time frame compared to other project phases compounds the situation; a very short delay can quickly double the estimated turnaround time. A solid execution plan is key. Here are five tips for building one:

Resource planning. Ensure you have the right resources for the job. This is not the time to rely on a novice or unproven employee. If anything, someone overqualified fits the bill. You want resources that can work under pressure. Also, arrange for ‘life-line’ resources for your primary resources doing the work. If/when you encounter a hiccup, it’s extremely helpful to get a second opinion and fresh perspective on the situation.

Setting expectations. Set realistic expectations with the plant operations team. If you are working on a brownfield project for a running plant, you are probably working within a production shutdown window. In this case, they are stopping production for you to do your work. They have communicated to upper management that the shutdown will only last for X number of hours. If you run into trouble and need more time, it’s likely to be a painful proposition. Set realistic expectations and expect to encounter a few problems along the way. Do not hope for a best case scenario.

Failing quickly. When problems occur and engineers find themselves in troubleshooting mode, they tend to put their heads down until the problem is resolved. This can be good and bad. The good: they will eventually solve the problem. The bad: they can burn precious hours out of your deployment plan while doing so. Make sure that they ‘fail quickly’ and call for help. Use a “15-minute rule” (call someone for help if a problem is not solved in an allotted – and agreed upon — timeframe). Ensure your team understands that burning many hours on a single issue will cause the team additional headaches.

Address hardware/construction needs. In automation, we sometimes find ourselves more focused on the software than the hardware. However, a deployment cannot be completed without having panels, network wiring, HMIs, etc. in place. Be sure that you communicate your hardware and construction needs early, and clearly, to the construction team and don’t let the deployment clock start until you verify that everything is ready.

Conduct development/testing on plant equipment. This may be the best tip of all. If you can manage to do your development work on the actual hardware that will run on the site, you can eliminate much of the deployment work all together. For example, if you can use the actual HMI servers and network equipment that will run the plant during development and testing, you will have effectively deployed the application before if ever leaves the test bench. This allows you to troubleshoot problems during a more convenient time.

Deployment is a critical activity in the lifecycle of an automation project. It can set the stage for your startup. But with proper planning you can greatly increase your chances of success. Do you have any other tips to share?

This post was written by Jason Montory. Jason is a senior project manager at MAVERICK Technologies, a leading automation solutions provider offering industrial automation, strategic manufacturing, and enterprise integration services for the process industries. MAVERICK delivers expertise and consulting in a wide variety of areas including industrial automation controls, distributed control systems, manufacturing execution systems, operational strategy, business process optimization and more.

MAVERICK Technologies is a CSIA member as of 3/20/2015