Cover story: Human-machine interfaces (HMIs) and historians differ but need to be tightly integrated to provide company operations with optimal value. Big data has little value without analysis and access in real time. Seven application examples explain HMI-historian integration benefits, including troubleshooting, analysis, and regulatory compliance.

Human-machine interfaces (HMIs) and historians differ in purpose but need to be tightly integrated to provide great value to companies’ operations. HMIs provide effective control and interactions between humans and machines. Historians collect high-speed time-series data to maintain a chronology of events. Seven applications examples help explain integration benefits.

Human-machine interfaces (HMIs) and historians differ in purpose but need to be tightly integrated to provide great value to companies’ operations. HMIs provide effective control and interactions between humans and machines. Historians collect high-speed time-series data to maintain a chronology of events. Seven applications examples help explain integration benefits.

Connecting to data

HMIs typically connect to programmable logic controllers (PLCs) to get their real-time data. Historians typically can connect to a HMI or directly to PLCs via OPC servers. Sometimes users want to connect to the HMI because certain tags have calculated values within the HMI. The preferred method should be that the historian connects directly to the PLC or source of the data. The objective for the historian is to have a complete chronology of process events for future analysis. HMI screens are typically being updated with new displays and graphics and may be shut down or restarted on occasion. When this happens, the data is not being collected properly and there are probably "holes" in the data-if the historian is connected to the HMI. By connecting directly to the PLC source, there is an independent connection that still collects data whether the HMI is running or not. Well-engineered historians also incorporate store and forward capabilities within the logger/collector components and should be located on the same machine as the source. This allows no data to be lost if network connections or communications go down between computers due to network failure or unreliable remote connections via satellite, cellular, or wireless connections. Also, data will not be lost when updating software to the latest software revisions.

Historian storage, performance

With today’s PC standard technology and capabilities, a typical historian system should be able to store and access more than 10 years of raw data. Aggregated manufacturing big data is good for certain reports, and historians should have the features to get access to this data, but it should not be stored as aggregates. Raw data streams are needed for true analysis. A well-performing historian should be able to easily exceed 1 million updates per second when storing data while retrieving more than 3 million updates per second at the same time. Users become quickly frustrated if they cannot get access to the data they need for analysis within a few seconds.

Historian ease of use

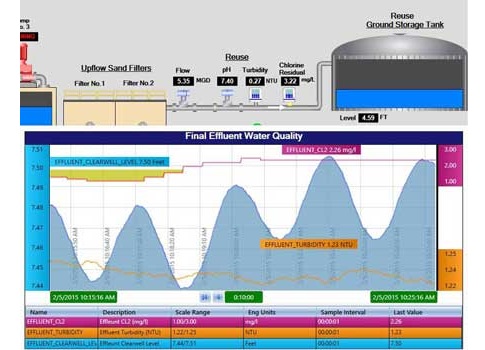

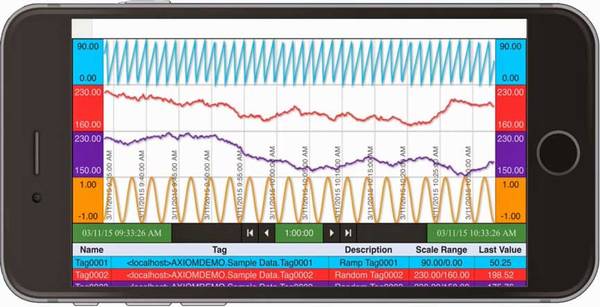

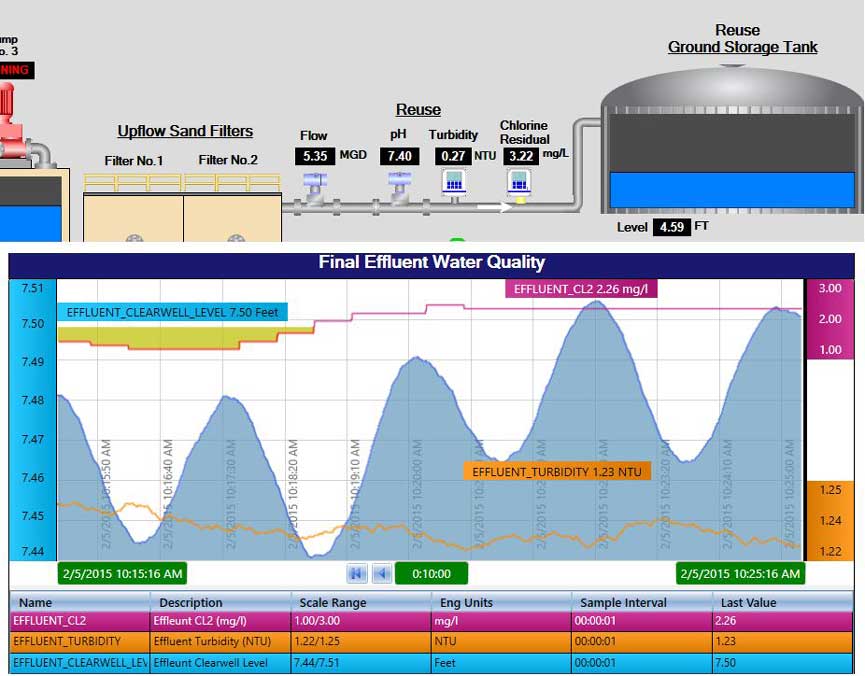

Users need intuitive tools to leverage historical data. They need easy access to the data tools that don’t require weeks of training. This historical data needs to be accessible to the operators within the HMI via client applications that use Microsoft ActiveX controls or preferably Microsoft .NET applications. If operators and engineers could view how different values were moving and setpoints were being changed, they could identify the rippling effect through the entire system and determine problems and solutions more quickly. The value is creating information that leads to faster decisions from this data as opposed to having a bunch of data.

The key is easy access to this data. The value of the trend data is that the user can ask "what if?" and pull the data together to verify the theory immediately. If they must go through IT to get data from the archives, which could take one or two days, they have lost that thought process. In reality, if analysis doesn’t happen in almost real time, it is not going to happen.

See the following HMI-historian benefits and application examples.

1. Troubleshooting with historical data

The HMI system indicated a high main bearing temperature on a hydroelectric turbine. The standard approach would be to take the unit offline, have it inspected, measure tolerances, change the oil and filters, and restart it in testing. By having over seven years of continuous data of bearing temperatures, it was noted there was no incremental increase to indicate a progressive failure. After comparing several trends, it was determined that the bearing lube oil cooling fan could be failing. Further investigation revealed carbon and corrosion on the contacts. The entire evaluation, isolation, and correction of the alarm took less than one hour and the hydroelectric turbine did not have to be taken out of service, with a cost savings of $20,000 for this one event.

2. Report analysis, research

An electric co-op sought a method to determine the amount of excess hydro that was running over the crest of the inflatable, rubber dam and down the stream. This excess water represented the opportunity to increase sales, provide a low-cost incentive rate, and spread fixed costs to lower the price of electricity in the community. It was determined the historian had the data tags available for the different measurements needed by reviewing four years of historical data. Results were compiled in one human day, and the approximate cost of the study was $1000. The estimated cost of a contract hydraulic engineer to perform a theoretical analysis based on historic stream flows and power use curves was $20,000, and the data set would likely have been less accurate than the trended values.

3. EPA reporting, annotations

Investigative and enforcement initiatives from the U.S. Environmental Protection Agency (EPA) are trending at historically high levels. Inspections can be extremely complex, time intensive, and may involve a number of internal team members to coordinate and fulfill requests made by EPA investigators and support staff. Clients that have accurate historical data reduce the tension between the investigation team and staff.

The EPA doesn’t feel that something is being hidden or covered up, and the staff of the company can quickly and easily answer questions about data anomalies. Historians with annotation capabilities contain additional operator notes within the time-series data documenting situations such as recalibration of equipment and sensors. When companies present complete historical data with sound explanations, a trust relationship is maintained as both sides can get and provide answers quickly with easy access of data. Proof of compliance can be verified quickly, resulting in the possible elimination of fines.

4. Root cause analysis

When an expensive pump (a $25,000 investment) failed, the operator claimed the equipment just broke without explanation. After reviewing the historical data in the historian, the real story was discovered. The operator wanted to temporarily lower a tank level below its setpoint. It was set to manual mode to override the controls, but then the operator was distracted with other items and forgot about the process. The pump ran dry and failed. Management was able to determine the root cause of the incident and put additional programming controls in place to handle a secondary controlled shutdown of the pump when placed in a manual mode to keep the problem from happening again.

5. DOT reporting

Pipeline clients allow U.S. Dept. of Transportation (DOT) personnel access to historical data for verification and analysis. Data from multiple pumping stations are replicated in centralized locations. Web-based tools are provided to company and DOT users to allow access to this data.

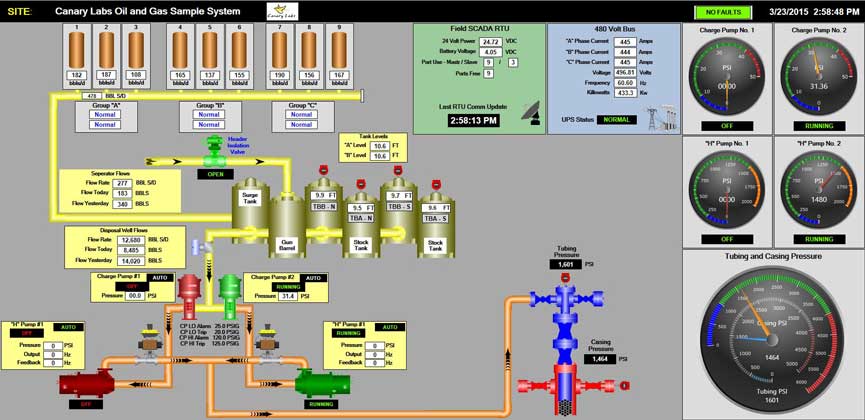

6. Asset management

The drilling and fracking industry faces some of the most challenging situations in managing and monitoring large numbers of assets that are constantly moving around. By having real-time data and reports, managers can be more efficient and make accurate maintenance plans for companies. This automated data collection helps in the following ways: saves on personnel resources, determines if certain equipment wears out sooner with more breakdowns or if operator errors are occurring, determines resources to schedule maintenance and rebuilds, and helps with resource allocation. Also, by having this historical data, further predictive analysis applications can be developed as more areas are identified for cost savings and better efficiencies.

7. Business intelligence

Companies are starting to see opportunities to leverage data from the plant historian and link certain data to other systems without replicating the master data. The key is the challenge of integrating this dissimilar data and transforming it into useful information. Those that are achieving this additional business intelligence are stating that it has become game changer for them.

Data availability, insights

Data is key when making decisions with HMI systems and historian systems. How users utilize this information will determine the value applied to the process. The decision can be based on a gut feel or actual data. The power is in the availability of data and relying on the abilities and skills of people to gain insight and take action to make improvements.

– Ed Stern is vice president, operations, Canary Labs; edited by Mark T. Hoske, content manager, CFE Media, Control Engineering, [email protected].

Key concepts

- Real-time historian information can be made available through human-machine interfaces (HMIs).

- Application examples show HMI-historian integration benefits for troubleshooting, faster analysis, regulatory compliance, and other ways.

- Better decisions faster can result from HMI-historian integration.

Consider this

Can real-time access to historian information through human-machine interface software help more people make smarter decisions more often?

ONLINE extra

This online version of this May 2015 Control Engineering cover story article has more details and links to related articles.

Control Engineering has an HMI page and an Information Control newsletter.