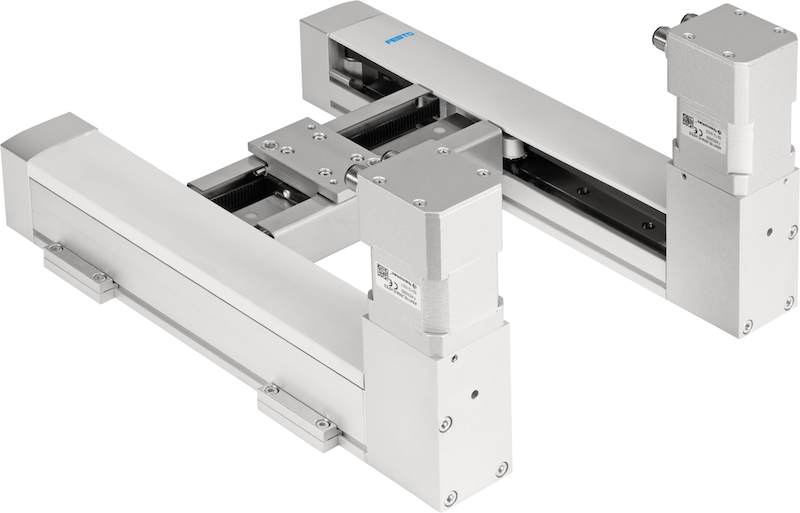

Festo's EXCM mini-H gantry is a handling system designed for small parts assembly and medical laboratory automation and is programmed with critical parameters for plug-and-work operation.

Festo’s EXCM mini-H gantry is a handling system designed for small parts assembly and medical laboratory automation. This X/Y planar gantry system is modular and flexible. It is also plug-and-work for quick and easy start up. The EXCM is already programmed with critical parameters for plug-and-work operation. A flexible interface concept provides users with a choice of TCP/IP Ethernet or CANopen for unlimited positioning, or digital I/O for up to 31 positions.

The design involves two motors and a toothed belt. Applications in small parts assembly include the feeding and screwing in of small components and flexible positioning of workpieces and components in assembly operations, palletization and depalletization, desktop manufacturing, and assembly.

Typical applications in the laboratory include transfer of micro-well plates, barcode-based sample identification, sample distribution, aspirating, incubating, dispensing, and archiving.

Festo

www.festo.com

– Edited by CFE Media. See more Control Engineering motor and drive products.

Festo is a CSIA member as of 3/5/2015