Advanced robotics, Internet of Things (IoT), virtual reality, and other technologies and concepts will help the manufacturing industry move forward, according to innovators from Italy and the United States at the recent i3 Forum in Chicago.

Ways to prevent the decline of manufacturing include greater use of digital manufacturing and advanced robotics, attracting more students to engineering, and creating greater flexibility and innovation. This was among the advice presented from U.S. and Italian manufacturing experts at the recent i3 Forum in Chicago.

Manufacturing challenges

The manufacturing sector is facing many challenges, although the future is bright as advanced technologies are now maturing with the Internet of Things (IoT), virtual reality, robotics, etc. Industry leaders highlighted challenges including the lack of young, skilled workers in the industry and the need to manufacture quality products faster and at a lower cost. Innovators highlighted what needs to happen going forward to prevent the decline of manufacturing including:

- Digital manufacturing

- Being open to adopting new technologies

- Attracting more skilled people to engineering schools

- Increasing flexibility and market innovation.

Manufacturing and robotics

Although a glaring challenge is the lack of young, skilled workers in the industry, automation is picking up the slack in production lines, according to industry leaders.

"We need to solve common problems with uncommon solutions," David Corsini, founder of Telerobot Labs said.

The acceptance of robots has been a big deal in the industry in addition to decreasing capital costs and easier programming. With the difficulty of finding workers, robots can’t be built fast enough. The ability for robots and humans to work collaboratively is vital to faster operations and abundant innovation (see Figure 1).

"Humans are underrated. They have an eccentric vision," Corsini said.

Innovators are very optimistic and pushing for incorporating more industrial robotics within additional industrial applications. Although there is a fear that robotics takes away jobs, this is not the case. Robots have many benefits including:

- Increased production without compromising product quality

- Flexible training

- Answering the decreased availability of skilled workers

- Creation of safer solutions in hostile or inaccessible environments.

One of the ongoing challenges within the industry is to maintain product quality while increasing production and at a low cost.

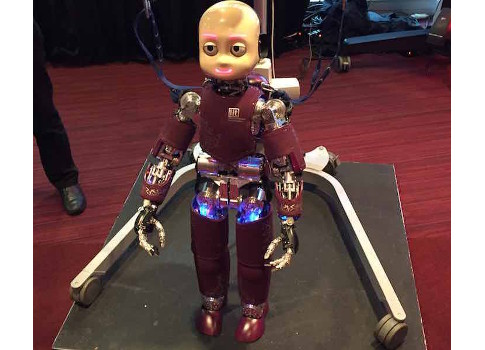

The iCub is a humanoid robot developed at the Istituto Italiano di Tecnologia in collaboration with Telerobot Labs as part of the EU project RobotCub that was launched in 2004. It was subsequently adopted by more than 30 laboratories worldwide. The iCub has 53 motors that give the robot the ability to move its head, arms, hands, waist, and legs. The robot also has the ability to see and hear, has a sense of proprioception, and movement using acceleromotors and gyroscopes (see Figure 2).

Marc Allen, president of Boeing International, capitalized on the fact that robots do not motivate, humans do. We need to let robots take over and solve the problems that are out there now, while humans continue to innovate and move the industry forward, according to Allen (see Figure 3).

One key challenge for robotics is the more complex the robot, the weaker it is. The size of the market is also a key barrier. Although these challenges exist, it’s a fact that robots are the solution for many issues within industries, Allen suggested.

"There is a black hole between robotics and big industries. We need to give problems to technology," Corsini added.

While barriers still exist when it comes to incorporating robotics within the manufacturing industry, advances are making greater integration of advanced robotics easier. Advanced technologies applied today can help corporations resolve challenges as they arise.

Emily Guenther, associate content manager, CFE Media, Control Engineering, [email protected].

ONLINE Extra

See related articles about robotics linked below.