The U.S. Dept. of Energy’s (DOE) Level VI energy efficiency standards for external power supplies are due to take effect beginning February 2016. This represents more than a simple tightening of the rules; the scope of the new regulation has been extended to include the higher power adapters found in a number of industrial applications.

The U.S. Dept. of Energy (DOE) published the Level VI standard in February 2014, which states that any external power supply manufactured after February 10, 2016, and shipped into the U.S. must meet the new efficiency targets. Although no final rulings have been announced, it is expected that other regions will likely follow the U.S.’s lead and make Level VI power supplies mandatory.

The Level VI specifications demand greater energy efficiency from low-power, standard-voltage or low-voltage units common in the consumer and office equipment sectors. Moreover, new classifications will be regulated for the first time, including multiple-voltage power supplies up to 250 W, and single-voltage power supplies over 250 W.

By including power supplies over 250 W, the latest specifications will have a greater impact on industrial applications, compared to Levels IV and V. Higher efficiency targets for units rated between 50 and 250 W may also affect certain types of industrial equipment. Power supplies that require approval and listing as a medical device are exempted.

Effect on industrial equipment

The marking protocol defines an external power supply as a device that converts ac power from a wall outlet into lower voltage dc or ac power to be used directly by electronic circuits. The power supplies are described as coming in a physical enclosure that is separate from the end-use product and usually provide power to the device through a separate cord and plug.

Equipment that could be affected by the move to Level VI includes high-power portable devices such as mobile test gear or laboratory instruments. The decision to use a physically separate external power supply may be driven by a desire to achieve the smallest possible enclosure size—for optimum portability—with a separate power supply that can be stowed conveniently.

An external power supply may also be suitable for equipment designed for a short period or on a semi-permanent basis. Examples include emergency air-conditioning or desiccating units, electronic signage for outdoor use, closed-circuit television (CCTV) monitors and equipment, and temporary lighting such as indoor LED lamps or stage lighting.

Power supplies up to 250 W

In general, manufacturers of external power supplies, including CUI, are extending the upper ranges of their product portfolios to include increased desktop power ratings and so offer greater flexibility for customers. Typically, the highest power ratings among desktop supplies today are in the 200 to 250 W range, they tend to have single-voltage outputs—usually 12 V, 24 V, or 48 V—which means they come within the basic range (over 6 V) described in Level VI.

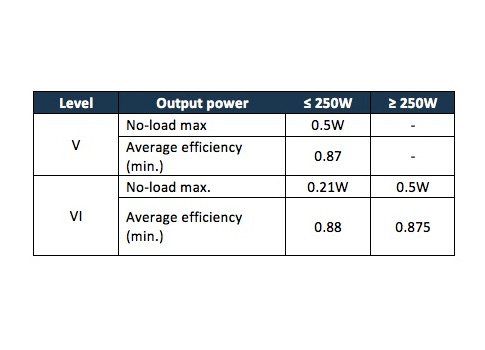

Manufacturers of these types of units, which currently meet efficiency Level V, need to be aware of the increased demands imposed by the forthcoming Level VI specifications. The minimum acceptable average efficiency is set to increase from 87% to 88%.

Significant changes for standby power are also going to be imposed. Under the Level V specification, units from 50 to 250 W are required to dissipate no more than 0.5 W under no-load conditions. Level VI reduces standby power to below 0.21 W for units from 49 to 250 W; the new over-250 W category specifies maximum standby power of 0.5 W.

The table shown summarizes the differences between the level V and level VI specifications for standard-voltage (not low-voltage) AC/DC power supplies over 50 W, which are likely to be used in industrial applications.

Adhering to the new standards

Since the first mandatory regulations on power supply efficiency were introduced in 2004, legislators have introduced progressively tougher specifications. Harmonizing the standards requires power supply vendors to adhere to the toughest specifications in force at any one time. In 2016, Level VI will take effect in the U.S. and will likely be enforced in Europe, as well.

As Level VI now includes specifications for power supplies over 250 W, a wider variety of high-power industrial applications are included within its scope. Equipment designers must pay greater attention to energy efficiency and be sure to specify power supplies confirming to the world’s new highest standard.

– Jeff Schnabel is vice president of global marketing at CUI. Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].

ONLINE extra

For more information, visit www.cui.com/efficiencystandards

– See related stories on efficiency standards below.