Machine safety validation is defined by the international standard ISO 13849-2, Part 2: Validation, which specifies the procedures and conditions for analysis and testing of the specified safety functions, the category achieved, and the performance level achieved. Some functional safety reliability results from a machines’ software design. See 5 steps often used during validation.

Machine safety "validation" and "verification" are not the same. Verification, as defined by ISO 13849 (Safety of machinery – Safety-related parts of control systems) is a step performed to confirm the correct design during the engineering phase. Validation is performed later in the development and is actually one of the final steps performed in preparation for commissioning. See five steps often used during validation.

Standard for validation

Validation is defined by ISO 13849-2, Part 2: Validation. This international standard specifies the procedures and conditions to be followed for the validation by analysis and testing of the specified safety functions, category achieved, and performance level achieved by the safety-related parts of the control system (SRP/CS) designed in accordance with ISO 13849-1.

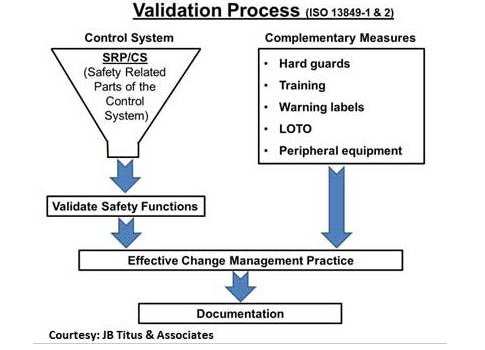

Doing this can be called a process because the overall intent is to test all of the designed functional safety measures provided and to ensure that any residual risks are tolerable. Validation considers more than just these safety functions within the control system as related to residual risks. There are also complementary measures that can affect final residual risk, in my opinion. And because a machine’s operational lifecycle may span several years and modifications, an effective change management system is strongly recommended.

Finally, the entire process must be documented throughout the machine’s lifecycle. The flow diagram shows a functional safety process applied to a machine’s operational lifecycle.

5 steps used in validation

Some specific steps I’ve seen used during the validation process include:

- Pulling a wire causing a fault to witness an intended safety function.

- Turning off power to see if the machine actually moves to its designed safe position(s).

- Actuating an e-stop device to validate zone and/or area results.

- Removing power to confirm that friction brakes are fully engaged and stopping distances are achieved.

- Disconnecting a network cable to ensure designed behavior is achieved without communication.

All of these safety measures are needed to validate reliable operation of safety devices and circuits after they have been fully implemented.

Software-based safety

Over the past 15 years there’s been a global trend to increase machine guarding using software-based approaches. Therefore, a significant portion of functional safety reliability results from a machines’ software design. I believe that this is a major reason why the validation step has become a requirement. Software can be a significant source for unexpected hazards in the transference of new and retrofitted machines to production. Confirming through validation helps to achieve reliable tolerable risk.

– J.B. Titus, certified functional safety expert (CFSE), writes the Control Engineering Machine Safety Blog. Edited by Mark T. Hoske, content manager, Control Engineering, [email protected].

ONLINE extra

Any questions about functional safety testing? What do you do during functional safety tests for your machines or machinery line? Submit your ideas, experiences, and challenges in the comments section below.

Also see other posts in the Machine Safety blog

Machine safety: Verification is not validation

The safety standards maze, 3 comments: more standards, validation

Machine Safety: safety system validation and daisy divination

www.jbtitus.com for “Solutions for Machine Safety”