Yokogawa introduces low-capacity dual bent-tube Coriolis meter.

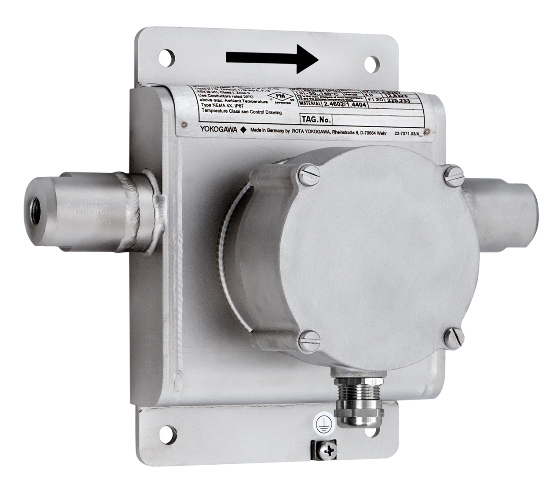

Yokogawa Electric Corporation has released its new RotaMass LR, which it characterizes as the the world’s smallest dual bent-tube Coriolis mass flowmeter. Designed to measure both liquids and gasses, the mass flow measurement spans from 0-40 kg/h, which corresponds to about 0-10.5 gph of water. The accuracy is ±0.15% for liquids and ±0.5% for gasses. The RotaMass LR aims at demand for accurate and stable measurement of fluids at low flow rates. Yokogawa has developed the low-flow Coriolis meter based on its proven dual bent tube design to overcome the current shortcomings of single-tube low-capacity flowmeters. These shortcomings include susceptibility to external vibrations and changes in ambient or process fluid temperatures which lead to less accurate and stable measurements in real-world conditions.

The dual bent-tube design decouples the core measuring element from process vibration that can cause fluctuating zero stability and decreased measurement accuracy. When fluid density changes, a single-tube Coriolis flowmeter can become imbalanced and start to behave like an emitter. This design remains balanced due to the equal mass change in both tubes and the absence of interference from the process piping. By design, it is insensitive to fluctuations in the ambient temperature and achieves excellent zero stability under changing process conditions. The two tubes are made from C-22 alloy, which is less susceptible to thermal expansion than conventional stainless steel.

The tube temperature measurement plays a key role in mass flow and density measurements. Normally, it is more difficult to measure temperature with Coriolis flowmeters that have tubes with a smaller surface area. This design solves that problem by using an inline temperature sensor, ensuring exact and fast measurements in process temperatures ranging from -50 to 150 °C.

Safety is a major concern with this design with a gas-tight, all-stainless-steel secondary containment that can handle pressures up to 65 bar. The meter itself can be used in high pressure applications up to 400 bar. A huge variety of welded process connections are available and no gaskets are used, minimizing the risk of leaks. Where fluid component separation and gas condensation are a concern, insulation and a heat jacket are available as an option.

Takashi Nishijima, a director and senior vice president, and head of the industrial automation platform business headquarters for Yokogawa says, "By measuring and controlling very low flow rates with a high level of precision, Yokogawa is helping its customers realize the VigilantPlant concept. We believe that this newly developed product gives customers a wider range of choices in multi variable process measurement and allows for greater accuracy and steady measurement in their utilization."

Edited by Peter Welander, [email protected]