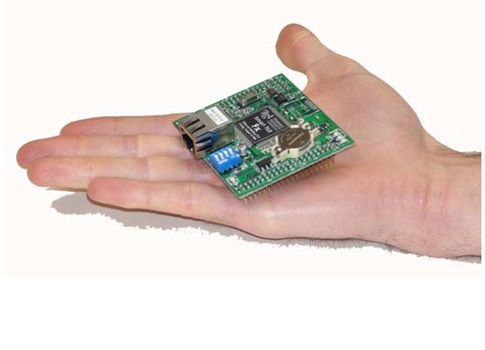

Triangle Research International Inc. (TRi) is supplying original equipment manufacturers with the brain of its top-of-the-line PLC in a small CPU board called SmartTILE (TRi Integrated Logic Engine), so OEMs can optimize their equipment with less time and effort.

Triangle Research International Inc. (TRi) introduces SmartTILE, a solution for original equipment manufacturers (OEMs) to custom build programmable logic controllers (PLCs). OEMs can now design the perfect programmable controller for their equipment. OEMs with their own in-house programmable controllers have a major advantage over competitors, with the ability to:

- Reduce many basic costs, including unused I/Os and ports.

- Save on expensive PLC field terminal wiring; designing all specialty I/Os into one printed circuit board (PCB) eliminates wiring.

- Customize the controller footprint to best fit into a specific control box and equipment.

- Optimize and maintain a consistent standard for the controls for a specific type and line of machines without creating a new controller for every new machine model released.

- Drastically cut new machine time-to-market.

- Have proprietary ownership of a programmable controller, program access security, and enhance the branding image of the company.

TRi, an OEM PLC specialist for 20 years, is supplying the brain of its top-of-the-line PLC in a small CPU board. By using SmartTILE, OEMs can now focus time and effort on the simpler effort of creating a complementary daughter PCB optimized to a specific line of OEM equipment. Insert the SmartTILE into the board, and the result is a proprietary PLC.

TRi’s programmable controller technology allows design of a reliable, powerful PLC with built-in Ethernet and up to 256 digital input/outputs (DIOs) and 12 analog IOs (AIOs). SmartTILE is programmable using a combination of industry-standard ladder logic and the BASIC language, and it supports open Modbus TCP/IP protocol, so it is easier to work with than other platforms, which often only C programming experts can handle. This results in shorter programming time, faster time-to-market, and lower programming costs. In the post-sales phase, SmartTILE gives OEMs greater peace of mind with significantly increased program reliability and ease of code maintenance.

SmartTILE is the standard brainboard of the TRi F-series Super PLCs. OEMs new to that platform can use a standard, off-the-shelf F-series PLC to create a prototype for a proof-of-concept design before proceeding to create customized PLCs. To facilitate prototype development, TRi supplies a SmartTILE PLC Development Kit that comprises a F1616-BA PLC, an additional SmartTILE, a licensed copy of the i-TRiLogi software, and documentation with schematic circuits demonstrating the interface to the digital, analog, and communication I/Os. The kit helps an OEM kick-start the design process.

To ensure a successful design of a custom daughter board, TRi can guide OEMs with comprehensive technical support. TRi can design and prototype the custom PLC for OEMs who prefer to outsource.

Triangle Research International Inc. (TRi)

– Edited by Mark T. Hoske, content manager, CFE Media, Control Engineering, [email protected].

ONLINE

A related TRi SmartTILE specification datasheet is available.