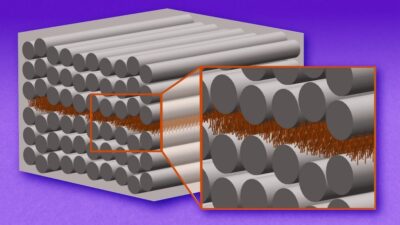

Laser camera combination technology is ideal for surface measurement in many industries. The camera detects a laser line projected onto an object at a specific angle. Height and width information is determined by triangulation.

Many industries require surface measurements, and laser camera combination technology can help. A camera detects a laser line projected onto an object, and then a triangulation calculation determines height and width. Many industries have applications that require smooth, sealed surfaces without gaps, ruts, or protrusions. These industries include glass, metal processing, plastics, tire, automotive, aerospace, and even highway road construction. When it comes to meeting the needs of these different industries, quality checks and process control based on measurement play a vital role.

In the past, lasers, mechanical measuring devices, and even wedges were used to check quality, but usually just as a spot check. Depending on the application, 100% inspection was too slow and required a large capital investment. A profile scanner, for example, has historically been very expensive and the units being scanned generally didn’t have an interface to decipher all the analog data produced by the scanner. Generally, a self-developed interface and HMI were required and the cost went up. If a company then wanted to capture the data and chart it for process control purposes, database development became necessary.

Surface quality control

Many companies are being asked to invest in ensuring the quality of the products they are producing. For example, the automotive industry is under the watchful eye of the consumer. Consumers expect each body panel on a vehicle to line up flush with the body panel next to it. Gap and flush measurement for quality control can take place while the body panels are placed onto the vehicle, or as a spot check on each vehicle. Consumers don’t want leaking sun roofs, glass panoramic roofs, or windshields. Leak protection depends on measuring the glue bead being applied for thickness.

The good news is that the demand for quality control measurement has sparked a whole new set of technologies entering the market at reasonable prices. Some laser systems now use a camera in combination with a laser for on-the-fly measurement at .01 mm. Some offerings use a simple browser for system setup; others have computer software that sets up a server or PC with a human-machine interface (HMI) and databases ready to go.

Laser camera combination technology is ideal for many industries, including the ones mentioned earlier. The camera detects a laser line projected onto an object at a specific angle. Height and width information is then determined by the triangulation method. Depending on the manufacturer and application, various distances are available. One company uses this technology to measure the depth of ruts in roads, measuring 4.2 meters wide at highway speeds day or night.

Put quality control measuring to work using many available options.

– Todd Belt is systems sales manager – VMT, Pepperl+Fuchs. Edited by Mark T. Hoske, content manager, CFE Media, Control Engineering and Plant Engineering, [email protected].

Online

See article "Laser light sensor helps quality control" below

See other machine vision coverage at www.controleng.com/machinevision.