According to the data in this report, benefits for using mobile devices on the plant floor include easier data access and increase productivity, 74% of users are allowed to use this technology on their plant network, and more than half of respondents expect an increase in mobility products and service spending in 2015.

Through the 2014 Mobility, Ethernet, and Wireless study, Control Engineering has identified the 10 trends about integration, use, and spending for mobility technologies and how they help users of automation, controls, and instrumentation to be more productive. These technologies are key components in plant-to-enterprise integration, industrial Internet, Internet of Things (IoT), and big data analytics and optimization.

- Technologies: Seventy-three percent of survey respondents use, buy, specify, or expect to specify a laptop within the next 12 months for business or professional purposes. Other top mobile devices used or expected to be used were Android smartphones (36%), Apple iPhones (35%), Android tablets (30%), and Apple iPads (27%).

- Usage: On average, 51% of company employees use mobile devices for work purposes. The majority interface with their mobile device(s) at their place of business (i.e. plant floor, operations), and three in 10 use these technologies at home and/or at customer locations.

- Mobile devices are generally used to manage work e-mail (89%), connect to company systems (79%), browse the Internet (54%), and view or monitor automation, controls, or instrumentation (40%).

- Benefits: The top five primary benefits of industrial use of mobility technologies identified by respondents were data accessibility (53%), increase productivity (29%), cost savings (27%), improved asset management (27%), and ease of use (27%).

- Permissions: Seventy-one percent of respondents’ facilities have a plant network, and nearly three-quarters of those facilities also allow the use of mobile devices on their networks.

- Expertise: Only 17% of respondents consider themselves to be experts on mobility technologies, while another 63% indicated they have “some familiarity,” up 5% from 2013.

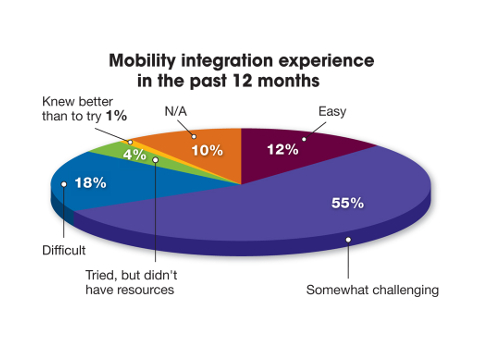

- Integration: Operations or engineering most often works on, services, or integrates mobile devices at 33% of respondents’ locations, closely followed by business IT at 29%.

- Security: Fifty-nine percent of respondents reported security issues as a main challenge with adoption or additional use of mobility technologies within their businesses.

- When implementing security for mobile devices, 60% follow set IT rules, 11% follow local department rules, and 7% allow a system integrator to decide for them.

- Ownership: Seventy-four percent of mobility technologies respondents use are provided to them by their company.

- Spending: When comparing the spending breakdown of the products, software, and services respondents purchase, 30% reported spending more on products and software than on services, and 27% said spending was equivalent across both categories.

- Outlook: Fifty-eight percent of respondents predict an increase in productivity at is directly relates to mobility in 2015, compared to only 47% for 2014, while 56% of respondents also expect an increase in mobility products and services spending.

Access the 2014 Mobility, Ethernet and Wireless report with additional key findings at www.controleng.com/2014MEW.

– Amanda Pelliccione is director of research, CFE Media, Control Engineering.