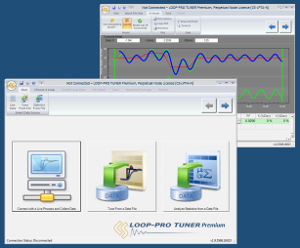

Software - Applications: Loop-Pro Tuner Premium is a process modeling and PID controller tuning software that integrates seamlessly with multiple PLC/DCS platforms for efficient online control loop analysis and optimization. This is a Control Engineering 2016 Engineers’ Choice finalist.

Loop-Pro Tuner Premium simplifies the optimization of today’s multi-platform and PID-based control environments.

It all comes down to modeling. Without an accurate model of a process’ dynamics, you can’t calculate the right parameters and you certainly can’t tune for optimal performance. In short, tuning software is only as good as its ability to handle the challenges of highly dynamic and complex industrial applications—what you know as the "real world.”

Loop-Pro Tuner Premium is process optimization software for industrial-grade applications. Equipped with a proprietary data modeling capability, it is the only software that accurately models oscillatory and noisy process data. It handles long Dead-Time with ease. It functions equally well in open-loop as it does in closed-loop. Loop-Pro has proven its value time and again in all manner of industrial applications—not just level control. If getting the model right matters, then there is only one choice and it’s Loop-Pro.

Loop-Pro Tuner Premium caters to today’s multi-platform control environments. The software’s auto-scan function automatically identifies PID controllers on your network. It supports major PLC and DCS platforms from leading process OEMs.

Control Station Inc., https://controlstation.com