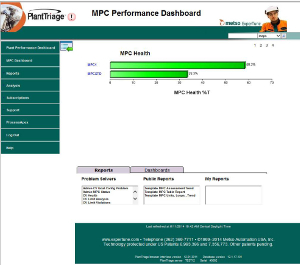

Software — Diagnostics: PlantTriage version 12 MPC monitoring gives the user the ability to monitor the performance of advanced controls. This is a Control Engineering 2015 Engineers’ Choice honorable mention.

PlantTriage version 12 MPC monitoring gives the user the ability to monitor the performance of advanced controls. It performs continuous assessments of the model predictive control (MPC). These assessments are used to diagnose issues with manipulated variables (MVs), disturbance variables (DVs), controlled variables (CVs), and the MPC itself. There are over 100 assessments of performance, which allows a high degree of specificity in the recommended corrective actions. Some of the new metrics include: effective controller on-time, controller health, time at constraints, and oscillation detection.

In addition to a detailed assessment of MPC performance, version 12 now presents the results in a new, more user-friendly browser interface. In response to client requests, the new interface is completely integrated with Metso ExperTune PlantTriage’s traditional monitoring of underlying regulatory control loops, allowing users to drill down directly from MPC monitoring to find root causes that may lie outside the MPC structure itself.

Metso ExperTune, www.expertune.com