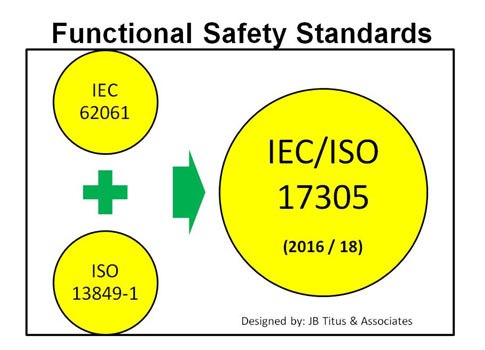

In a few years, could we just have one functional safety standard? The world has two predominantly accepted functional safety standards for machinery: IEC 62061, Safety of machinery: Functional safety of electrical, electronic and programmable electronic control systems, and ISO 13849-1, Safety of machinery - Safety-related parts of control systems - Part 1: General principles for design.

A joint working group is looking at global functional safety standard unification. At present, there are two predominantly accepted functional safety standards for machinery in the world:

- IEC 62061, Safety of machinery: Functional safety of electrical, electronic and programmable electronic control systems, and

- ISO 13849-1, Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design

These two standards are often used together by machine original equipment manufacturers (OEMs) to design and build the safety-related parts of the machine control system. Safety experts generally feel that, for a machine’s safety system, 62061 handles the more complex components best and that 13849-1 handles the less complex components and field devices best for a total solution. They have been in use together for the past eight years and were needed in part because technology advancements required more guidance for their proper application to achieve intended safety functions reliably.

Work is underway

A joint working group has been formed and is currently working on this project. The new combined functional safety standard has been designated IEC/ISO 17305 and is tentatively scheduled for release in 2016 with a two-year transition period.

In my opinion, for 17305 to be successful it should:

- Make life simpler for users

- Resolve some existing issues

- Capitalize on the best achievements of each standard.

It seems this direction has commitment from standards bodies because maintenance work on 62061 and 13849-1 has virtually stopped. It also seems that the existing updated standards are improving levels of safety because they are requiring designers to incorporate all aspects relative to the life cycle reliability of components used in safety circuits. Safety rated components are recommended while allowing standard components. However, reliability data is required by the calculations for all safety rated or standard components engineered into a safety circuit.

Even though many countries have their national (or domestic) safety standards, global trade is increasing and this activity increases the need for global standards. As the merging process continues, it is not anticipated that newer, more complex requirements will be added. The bottom line is that it appears global industry is driving to achieve clarification and simplification for one standard, helping OEMs to provide safer and fewer designs more competitively.

Has this presented you with any new perspectives? Do you have some specific topic or interest that we could cover in future blog posts? Add your comments or thoughts to the discussion by submitting your ideas, experiences, and challenges in the comments section below.