The Energy Department announced $3 million for ten new projects for the High-Performance Computing for Manufacturing (HPC4Mfg) Program, which is designed to enable private-sector companies to use high-performance computing resources at the department's national laboratories to tackle major manufacturing challenges.

The Energy Department announced $3 million for 10 projects designed to enable private-sector companies to use high-performance computing resources at the department’s national laboratories to tackle major manufacturing challenges. The projects range from improving turbine blades in aircraft engines and cutting heat loss in electronics to reducing waste in paper manufacturing and improving fiberglass production.

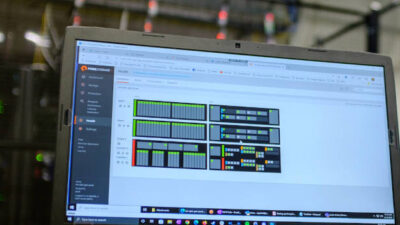

Led by Lawrence Livermore National Laboratory (LLNL), with Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory as strong partners, the High-Performance Computing for Manufacturing (HPC4Mfg) Program is designed to increase the efficiency of manufacturing processes, accelerate innovation, and improve the quality of clean energy products.

Assistant Secretary Danielson said, "The HPC4Mfg initiative pairs leading clean energy technology companies with the world-class computing tools and expertise at our national labs to drive down the cost of materials and streamline manufacturing processes. The ultimate goal of their collaboration is to increase our global competitiveness in the race to develop clean energy technology and jobs."

This effort will also advance President Obama’s National Strategic Computing Initiative, which the President unveiled in July 2015, calls for public-private partnerships to increase industrial adoption of high-performance computing.

Each Phase I project has been selected for approximately $300,000 to fund the national labs to partner closely with each chosen company to provide expertise and access to high-performance computing systems aimed at high-impact challenges.

Under the HPC4Mfg program, the ten selected projects will leverage the national labs’ high-performance computing capabilities to apply modeling, simulation, and data analysis to industrial products and processes to lower production costs and shorten the time it takes to bring new clean energy technologies to market. These Phase I projects are aimed at lowering the barrier of entry for industry to use high-performance computing and validate its use in improving manufacturing.

– Edited from a Department of Energy press release by CFE Media. See more Control Engineering energy and power stories.

View the ten project descriptions here.