Respondents to the Control Engineering 2014 Mobility, Ethernet, and Wireless Study identified 10 important high-level findings regarding Ethernet technologies.

Respondents to the Control Engineering 2014 Mobility, Ethernet, and Wireless Study identified these 10 important high-level findings regarding Ethernet technologies:

- Technologies: Seventy-five percent of survey respondents use, buy, specify, or expect to specify Ethernet switches within the next 12 months for business or professional purposes. Other top Ethernet technologies used or expected to be used were wires or cables (69%), networks (66%), routers (62%), and connectors (52%).

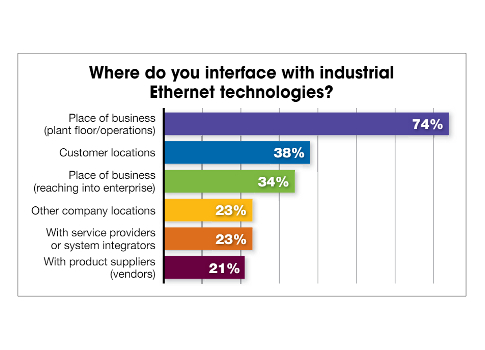

- Usage: The majority of respondents interface with industrial Ethernet technologies at their place of business (i.e. plant floor, operations), while 38% use these technologies at customer locations and another 23% use them when meeting with service providers or system integrators.

- Benefits: The primary advantage of using Ethernet technologies is data access, according to respondents. Other benefits include ease of use (39%), cost savings (27%), better asset management (23%), and increased productivity (22%).

- Expertise: Only 38% of respondents consider themselves to be experts on Ethernet technologies, while another 53% indicated they have “some familiarity.”

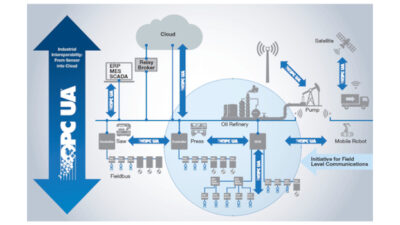

- Integration: Operations or engineering most often works on, services, or integrates Ethernet technologies at 40% of respondents’ locations, followed by business IT at 23% and manufacturing IT at 16%.

- Five in 10 respondents indicated their controls, automation, and/or instrumentation are only somewhat integrated with Ethernet technologies, compared to 29% being highly integrated and only 7% not integrated.

- Sixty-two percent of respondents claimed their Ethernet integration experiences in the past 12 months were somewhat challenging—compared to 37% in 2014—and 14% required outside assistance.

- Security: Forty-five percent of respondents reported security issues as a main challenge with adoption or additional use of Ethernet technologies within their business.

- When implementing security for Ethernet technologies, 61% follow set IT rules, 15% follow local department rules, and 8% allow a system integrator to decide for them.

- Ownership: Eighty-nine percent of Ethernet technologies respondents use are provided to them by their company.

- Spending: When comparing the spending breakdown of the products, software, and services respondents purchase, 45% reported spending more on products and software than on services—compared to 59% in 2014—and 26% said spending was equivalent across both categories.

- Outlook: Forty-four percent of respondents predict an increase in productivity as it directly related to Ethernet in 2015, while 49% also expect an increase in Ethernet products and services spending.

- Protocols: The top three Ethernet protocols used in respondents’ facilities are EtherNet/IP (69%), TCP/IP and UDP (61%), and Modbus TCP (47%).

In December 2014, Control Engineering surveyed audience members responsible for purchasing or specifying technologies or services that use, connect with, or support mobility, Ethernet, or wireless technologies for the 2014 Mobility, Ethernet, and Wireless Study.