Ethernet

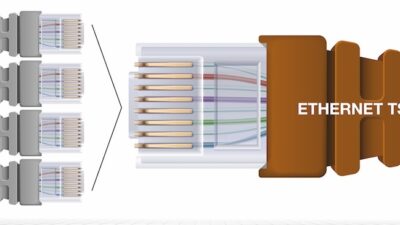

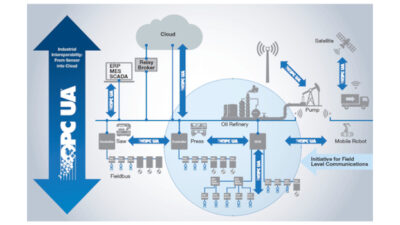

Ethernet communication protocol (networking software and hardware standards) and its variants are detailed in IEEE 802.3-2018 - Standard for Ethernet at https://standards.ieee.org/standard/802_3-2018.html. Variants may not be interoperable in their software compatibility or physical layer wires, plug and connector designs without gateways or modules to translate and interconnect.