Of course dollars count. Throwing automation dollars at a project isn't the preferred method for end-users, for system integrators who may help with implementation, or for vendors. Even vendors—who usually don't mind receiving money—would rather receive a bit less revenue, if it ensures customers' needs are met or exceeded.

Of course dollars count. Throwing automation dollars at a project isn’t the preferred method for end-users, for system integrators who may help with implementation, or for vendors. Even vendors—who usually don’t mind receiving money—would rather receive a bit less revenue, if it ensures customers’ needs are met or exceeded.

Everyone’s challenged with offering the best value proposition: choosing the right set of automation and controls in light of lifecycle costs, business issues, ease of use, integration, and application-specific considerations.

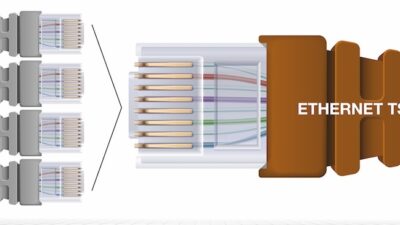

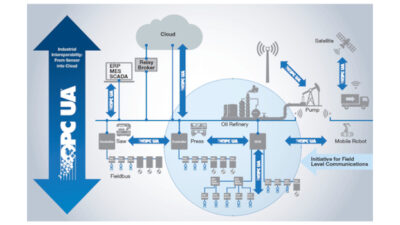

The cover story “Ethernet’s in Control” shows how Ethernet resolves some of the ongoing “fieldbus wars” issues. Gary Mintchell, senior editor, explains that Ethernet, already part of most plant’s information systems, is being used increasingly to connect controllers with remote I/O modules as a fieldbus.

With more Ethernet -based devices, equipment, and connections available and emergence of several industrial protocol options, manufacturers have made it easier for users to accept lower-cost Ethernet in manufacturing applications. Vendors say Ethernet-based controllers and I/O modules are more readily accepted. Tell us what you think in a quick one-question reader survey at Control Engineering Online , www.controleng.com . We’ll report on results next month.

In another example of making dollars count, learn about a Genetech pharmaceutical application with more than 6,000 I/O points. David Harrold, senior editor, shows how a tightly integrated implementation can deliver flexible, agile, repeatable manufacturing in a highly complex batch application.

The cliche says time is money; software to help with instrumentation specifications can help save both. Tracy Coates, contributing editor, describes how in an article about instrumentation selection.

In a wider view , National Association of Manufacturers (NAM, Washington) remains consistent in views expressed with its annual survey—U.S. manufacturers oppose additional interest rate hikes by the Federal Reserve. I see irony when U.S. monetary policy intended to calm a get-rich-quick stock market instead makes business more difficult for those creating real value.

Jerry Jasinowski, NAM president, says manufacturers “are in the front lines of economic competition and should be heeded.” NAM promotes use of advanced technologies and continuous workforce training as part of its recommendations for expanding economic growth. For more NAM survey results, see “News.”

For more measurement, Control Engineering shares its readers’ wisdom in the “Product Focus” feature, this month examining trends in discrete sensors. Also find more research results with the online version of this article at www.controleng.com .

Your input counts . Help us continue to ensure we bring value to you—if you’re among several thousand readers to receive our every-third-year reader survey, please take the time to fill it out completely and send us the results. Perhaps the monetary questions will be less sensitive, knowing that we (and the U.S. government census) hold individuals’ information in strictest confidence. We’ll report on these readers’ trends in the August edition and use the information to help shape future editorial coverage.

We appreciate adding value to your workplace and continue to thank you for help in return.

| Author Information |

| Mark T. Hoske, Editor-in-Chief [email protected] |