Network Integration - Ethernet hardware: TURCK Industrial Ethernet Multiprotocol technology simplifies industrial Ethernet for Distributed I/O, employing one device for three protocols—EtherNet/IP, Modbus TCP and PROFINET—to create easier integration with host control systems. This is a Control Engineering 2014 Engineers’ Choice finalist.

TURCK Industrial Ethernet Multiprotocol provides an innovative approach to industrial Ethernet I/O by delivering a simplified and reliable solution across all distributed I/O families, including on-machine, in-cabinet, modular and block I/O applications. Industrial Ethernet Multiprotocol allows operators to employ one device for three protocols—EtherNet/IP, Modbus TCP and PROFINET—creating easier integration with host control systems.

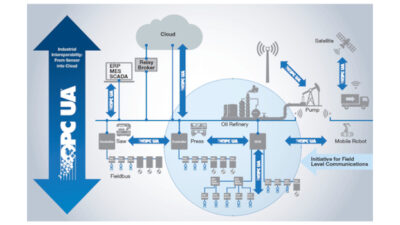

An Ethernet device featuring TURCK Industrial Ethernet Multiprotocol can be applied in any application that uses a host system with Modbus TCP (client), EtherNet/IP (scanner) or PROFINET (master). Upon network power-up, the device will recognize the master network protocol and automatically self-configure. While the device can combine multiple Ethernet protocols, it will only allow one Ethernet master to control the outputs while the input and diagnostic data is available to other protocols.

Industrial Ethernet Multiprotocol technology offers users the exclusive advantage that does not require them to configure their device based on the Ethernet host system that will be deployed. This simplifies operations for customers who manufacture or design equipment for an end-user base that has differing preferences between industrial Ethernet protocols.

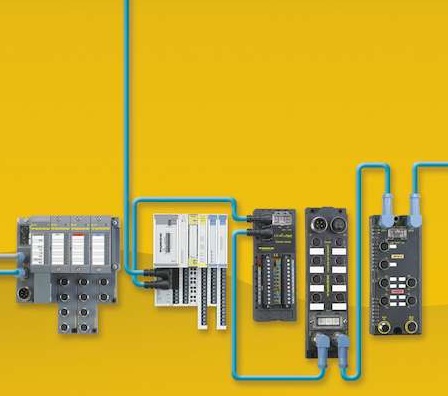

Industrial Ethernet Multiprotocol is available for a variety of TURCK industrial Ethernet devices including BL20 in-cabinet modular I/O gateways, BL67 on-machine modular I/O gateways, BLCompact on-machine block I/O, in-cabinet block I/O stations and advanced I/O (AIM) on-machine block I/O stations.

www.turck.us

www.turck-usa.com/Products/Networks/Industrial_Ethernet/

TURCK