Software - Control design: The TwinCAT 3 SOA-PLC is a software solution for more efficient, secure, and standardized communication in the implementation of Smart Factories and Industry 4.0 concepts. This is a Control Engineering 2016 Engineers’ Choice finalist.

Combining IEC 61131-3 functions and secure OPC UA communication, Beckhoff Automation offers an SOA (service oriented architecture) PLC for more efficient, secure, and standardized communication to implement Smart Factories. Industry 4.0 and Internet of Things concepts depend upon capable networking and communication technologies. This requires services to communicate with each other directly, and products to control themselves, instead of top-down communication from the ERP system via MES, PLC, and ultimately down to the sensor.

Sensors, RFID chips, PLCs, and other embedded systems provide important data for production in industrial applications. In conventional control architectures, data requests are initiated either cyclically or are event-triggered, always in response to requests from above, i.e. from the client level. The lower level always acts as a server and responds accordingly. In other words, an RFID reader or PLC controller are not intelligent in terms of communication. In Smart Factories, physical, real systems and virtual, digital data merge forming intelligent, self-organizing production units. They acquire the data needed for this purpose autonomously. This means all devices and services must be able to communicate with each other independently, irrespective of the manufacturer, operating system, hierarchy, or topology.

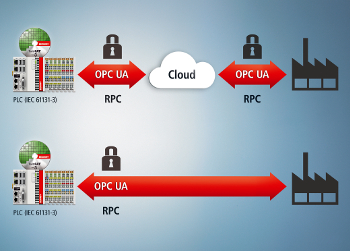

Beckhoff has integrated the OPC UA client function blocks in the PLC, which are standardized by PLCopen in cooperation with the OPC Foundation. As an OPC UA client, the controller can play the active, leading part, in addition or as an alternative to the conventional role allocation. The PLC is able to exchange complex data structures horizontally with other controllers, or vertically call methods in an MES/ERP system via an OPC UA server, e.g. to retrieve new production orders or write data to the cloud. This enables production lines to become autonomously active. In combination with integrated OPC UA security, this is a key step towards Industry 4.0.

Beckhoff Automation, www.beckhoffautomation.com