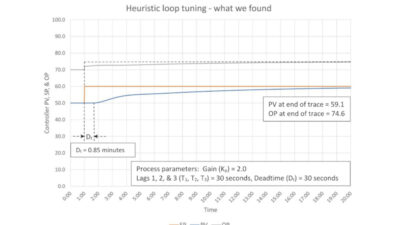

PID, APC

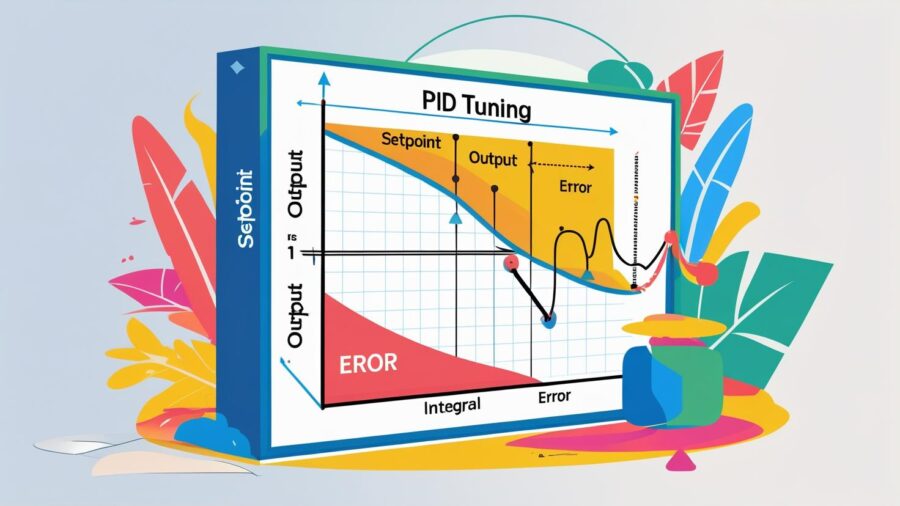

Advanced process controls (APC) refers to a sophisticated and growing collection of algorithms (software) applied used in logic devices for making continous, batch or hybrid operations. Examples include proportional-integral-derivative (PID) software.