Siemens Automation & Drives says its $3.5-billion agreement to acquire UGS Corp., a provider of product lifecycle management (PLM) software and services, would make Seimens the first worldwide manufacturing industries supplier of software and hardware across the full product lifecycle. Manufacturing hardware and software technologies are converging with product lifecycle, manufacturing, and...

Siemens Automation & Drives says its $3.5-billion agreement to acquire UGS Corp., a provider of product lifecycle management (PLM) software and services, would make Seimens the first worldwide manufacturing industries supplier of software and hardware across the full product lifecycle. Manufacturing hardware and software technologies are converging with product lifecycle, manufacturing, and enterprise information technologies in many segments, Siemens says. The two companies began their business relationship in 2003 with joint projects addressing digital manufacturing technology.

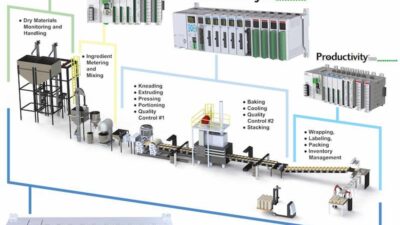

The offer from Siemens A&D is based on what the company is calling “a comprehensive, technologically consistent product portfolio (Totally Integrated Automation)” that will enable Siemens to provide “every customer with an integrated package of engineering and automation systems.” By integrating more than 3,000 software engineers of UGS, the Group will employ around 7,000 software experts.

“With the acquisition of UGS,” says Klaus Kleinfeld, president and CEO of Siemens AG, “we combine its competence in digital factories with our leading know-how in industrial automation. This combination makes our customers’ processes faster, better, and more cost efficient. With the unique combination, we underscore our position as a trendsetter in automation systems and bring this business into a new dimension.”

Tony Affuso, chairman, CEO and president of UGS, says, “The combination of Siemens and UGS is a game-changer in the global PLM industry due to our shared vision of ‘Totally Integrated Automation.’ Our customers win the long-term security of their system investments provided by one of the world’s largest, most successful and innovative companies.”

Siemens says A&D would become the first supplier for manufacturing industries to provide an end-to-end software and hardware portfolio encompassing the complete lifecycle of products and production facilities. The transaction is subject to approval by relevant authorities.

UGS software includes collaborative product data management (cPDM), computer-aided design/computer-aided manufacturing/computer-aided engineering (CAD/CAM/CAE), and digital manufacturing simulation. Siemens says UGS holds strong revenue and market share positions globally in digital manufacturing and cPDM, the fastest-growing segments within the PLM market. In fiscal 2005, UGS reported revenue of nearly $1.2 billion; in third-quarter 2006, the company reported the 13th consecutive quarter of year-over-year revenue growth.

www.usa.siemens.com

www.ugs.com