KW-Software develops training and demonstration programs in its role as a competence center. Video: Dan Swanson discusses the capabilities of the center and a brief description of Profinet.

In order to support Profinet users in the best possible way, the Profibus User Organization has established a network of competence centers to work with users and serve as test facilities. Phoenix Contact and it’s software subsidiary, KW-Software, are part of this network serving as an expert for automation technology as well as the independent test lab. The KW-Software office in Ann Arbor, Mich., is the 50th PICC (Profibus and Profinet Internal Competence Center) where it offers customers support, training, and integration of technology for related products through an entire lifecycle.

In the video, KW-Software senior application engineer, Dan Swanson, discusses Profinet and KW-Software’s role as a Competence Center, and displays how hardware from different vendors can work together in unison when using Profinet. KW-Software features a solution-based business model for IEC 61131 Control Technology, IEC 61508 Safety Technology and Profinet.

Using the centers of competence, automation device manufacturers, suppliers, and users can get access to a comprehensive range of services during the entire lifecycle phases of devices/components and systems. The Phoenix Contact/KW-Software Competence Center sees itself as service partner from the first concept of a component up to the retrofit of an existing system. This way, customers can use the development and application experience of a leading automation manufacturer.

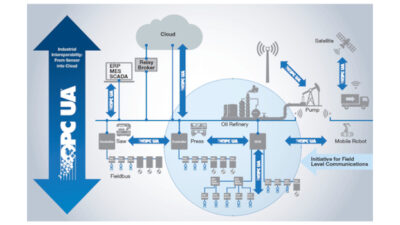

Profinet is an advanced industrial Ethernet solution for networking production assets (sensors, actuators, sub-systems and production units) and equipment such as PLCs, DCSs, and enterprise-wide IT systems. It is fully compatible with office Ethernet and uses many of its features. However there are differences designed to accommodate industrial users since office Ethernet is not capable of the real time performance required of industrial automation applications.

Based on its experiences with Profibus, a real-time fieldbus family that is broadly deployed around the world, PI Working Groups comprising more than 500 experts from major automation suppliers spent many man years creating a comprehensive real-time Ethernet solution for automation.

The organization says that the solution is able to operate in difficult industrial environments and is capable of delivering the speed and precision required by manufacturing plants. It can also provide additional functions, including safety, energy management, and IT Integration in combination with control and monitoring functions.