Oak Brook, Ill. - Ethernet and industrial networks can interconnect manufacturing and processes with the enterprise, bringing significant value to the supply chain, according to network experts participating in SupplyChainLinkExpo, a two-day online conference and trade show.

NOTE-TIME CHANGE:Due to technical difficulties, this roundtable on Ethernet and industrial networks will now be presented on Thursday, October 18 at 1 p.m. We apologize for the inconvience. Please view other scheduled events and information, Oct. 17-18, and afterward in archive for 90 days, at https://www.supplychainlinkexpo.com .

Oak Brook, Ill. – Ethernet and industrial networks can interconnect manufacturing and processes with the enterprise, bringing significant value to the supply chain, according to network experts participating in SupplyChainLinkExpo , a two-day online conference and trade show.

The roundtable, moderated by Control Engineering (Cahners Business Information), will be Oct. 17 at 3:30 p.m. EDT and be available for viewing for 90 days thereafter. Attending the roundtable is free; register at https://www.supplychainlinkexpo.com .

Roundtable participants are: Michael J. Bryant, Executive Director, Profibus Trade Organization and AS-i Trade Organization (Scottsdale, Ariz.); David Glanzer, Director of Technology Development, Fieldbus Foundation (Austin, Tex.); and Frank Wood, Executive Director, ODVA and ControlNet International (Boca Raton, Fla.). Moderator for this roundtable is Mark T. Hoske, editor in chief, Control Engineering (Oak Brook, Ill.).

Points expected to be covered in the ‘Make Pavilion’ roundtable, ‘Ethernet and Industrial Networks,’ include:

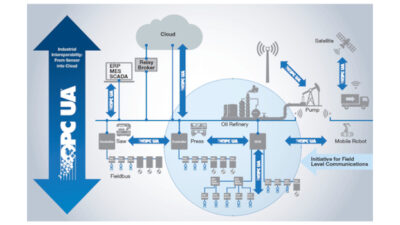

Industrial networks: types, benefits, architectures, and applications;

Ethernet for manufacturing or process control: benefits, challenges, politics, and choices;

How to decide if an industrial network or Ethernet should be used; and

Recommendations and contacts for more information.

Among key recommendations, ODVA/ControlNet’s Frank Wood says, ‘It’s important that we embrace Ethernet and look at taking a holistic approach to implementing networks.’

Fieldbus Foundation’s Dave Glanzer points out, ‘Acceptance of Ethernet technology by equipment suppliers, integrators, and end-users is a key enabler for cost-effective plant information integration.’

And Profibus Trade Organization/AS-i Trade Organization’s Mike Bryant adds, ‘Individual networks may solve problems that Ethernet cannot, and OPC DX solves Ethernet compatibility issues.’

The roundtable also will cover OPC DX, which stands for OPC Data Exchange, an initiative announced Sept. 11 by OPC Foundation (Boca Raton, Fla.). OPC DX defines standard set of interfaces for interoperable data exchange and communications across Ethernet networks and with industrial networks. (See also Control Engineering Online Daily News, Sept. 12 ). OPC DX working group is supported by ControlNet International/ODVA; Fieldbus Foundation; and Profibus International.

Panelists will also discuss how traditional industrial networks:

Connect islands of automation;

Reduce initial cost over hard wiring with average savings of more than 40%, according to case histories;

Reduce life-cycle maintenance costs;

Increase plant productivity by cutting unscheduled down time;

Reduce mean time to repair with improved diagnostics and preventive maintenance;

Serve as conduits to deliver and receive information to areas outside production; and

Provide information to plant data servers.

Ethernet, widely used network ‘above’ the plant floor, continues to be adapted for rugged environments, panelists will explain. No data conversion is needed when passing info to other areas. Ethernet knowledge is available, and its use can lower costs, especially if it reduces the number of networks needed. Because of security and traffic concerns, however, a dedicated Ethernet network may be needed.

Further panel discussion includes details of industrial network and Ethernet solutions offered by each of the three organizations, and when to consider Ethernet or a traditional industrial network.