NI Days 2015 Chicago highlighted the latest advances in platform-based technologies and 5G research to overcome escalating complexity and expand the Internet of Things (IoT). Smart data was also a main focus at the event, featuring methods to better save data for analysis and future applications. The National Instruments event was held on Oct. 15 at Navy Pier, Chicago.

By 2050, about 50 billion devices will be connected, most wirelessly, yet 85% of embedded devices today are not connected, according to Richard McDonell, technical director, Americas, at National Instruments (NI). To shed light on one of the greatest challenges in today’s industry, the NI Days 2015 Chicago kicked off with keynote speeches highlighting the latest advances in platform-based technologies and fifth generation mobile wireless technology (5G) research to overcome escalating complexity and create the Internet of Things (IoT). Smart data was a main focus at the event, including ways to better save data for analysis and future applications. The traveling one-day event from National Instruments was held on Oct. 15 at Navy Pier, Chicago.

Five key areas of IIoT

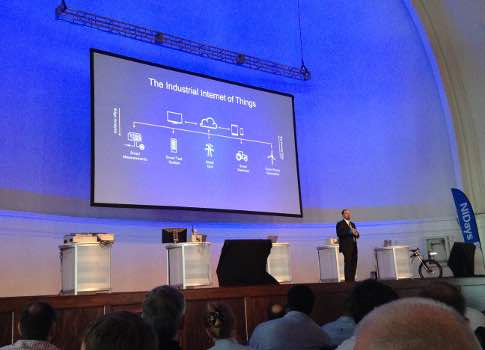

According to John Graff, vice president of corporate marketing at National Instruments, there are five key areas where IoT is implemented in the industrial sector, where the concept is called the Industrial Internet of Things (IIoT):

- Smart measurements

- Smart test systems

- Smart grid

- Smart machines

- Smart power generation.

Smarter measurements, test systems, machines

Smart measurement is important especially in mechanical and electromechanical systems due to the large amount of data created in the process. Today, using traditional measuring methods, only 22% of the data collected during the process is good enough to be analyzed, and only 5% of the data is actually analyzed. With the small portion of analyzed data, critical decisions and business analysis are difficult to make. To use big analog data more efficiently, smart measurements need to be enabled.

The first step to enable smart measurement is to save and identify measurable data from machines. With the rising complexity of wireless tests due to the increasing use of 5G, Cellular, global position systems (GPS), near-field communication (NFC), Bluetooth (IEEE 802.15.1), and IEEE 802.11 wireless local area networks, smart wireless test systems, and software are needed. With the right architecture, the smart testing system will look like a set of "systems of systems" that accommodates multiple standards, ports, and devices that allow data to flow among machines testing tools, smart grids, the computers, cloud, and smart phones.

Smart power grid, smart power generation

Another important area of IIoT is related to smart grid and power generation. According to McDonell, there is a strong correlation between the gross domestic product (GDP) per capita of a country and its electricity consumption per capita, showing the impact of electricity on an economy. Smart data and smart measurement enable better scheduling of the power grid machines’ uptime and freezes machines at peak power consumption to achieve higher utilization of energy.

An example in India using such a power grid allows 100 MW to serve 250,000 homes. It’s an example of taking existing grids, applying smart measurements, and optimizing them to get better results. To show the impact of energy efficiency improvement, McDonell stated that 1% of industry efficiency savings means the saving of $66 billion in equipment fuel, $27 billion in rail productivity, $90 billion in oil and gas capital expenditure, or $30 billion in aviation fuel.

Best practices for saving measurable data

To conduct smart measurement and testing, the first step is to save the data correctly. In another session, National Instruments presented methods on how to select a file format, organize metadata, and analyze, report, and share the results.

The need for 5G

One of the most important components of IoT is the development of the 5G network. Today, there are four vectors of 5G research that the industry is focusing on: massive multiple-input and multiple-output (MIMO), wireless networks, physical layer (PHY) enhancements in the OSI model, and mmWave. mmWave, for example, provides greater spectrum opportunity. National Instruments partnered with research institutes and network companies to explore candidates for 5G connection.

"The Industrial Internet is indeed transformative. It will change the basis of competition, redraw industry boundaries, and create a new wave of disrupted companies," said McDonell, quoted at the World Economic Forum.

– Joy Chang is digital project manager at CFE Media, [email protected].

ONLINE extra

National Instruments

See additional stories about the IIoT linked below.