myDIALS 3.0 upgrade enables performance analysis, in context, through dynamic time control.

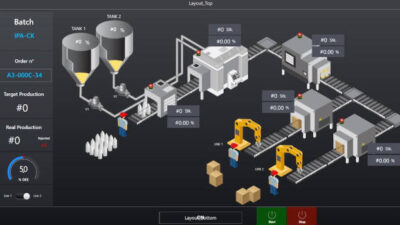

myDials, an operational performance management software company based in Lafayette, CO, has introduced myDIALS version 3.0, an upgrade to its software as a service (SaaS) dashboard application that delivers "every person analytics," including real-time scenario analysis. The software enables executives, engineering management and others to monitor performance, identify and characterize performance problems, make rapid decisions, and take corrective action to fix issues based "right-time actionable metrics."

Vince Aurora, plant manager for the Adelaide Brighton Cement Plant, said, "myDIALS’ strength is its ability to display and provide drill-down access to information from the systems that we already have in place. myDIALS version 3.0 offers drill-in analysis, analytic trend charts and the ability to perform what-if scenarios, which makes business intelligence for all levels of management a reality."

| myDIALS 3.0 lets users determine the root cause of performance issues. |

myDIALS 3.0 provides all users with advanced interactive performance analysis capabilities and intuitive context-setting features, including what myDials says is an industry-first dynamic time control approach. The system puts the entire dashboard into a time context to quickly obtain the big picture overview of performance trends, as well as the level of detail required to determine an issue’s root cause. Users can "zoom in" or "zoom out" along the time hierarchy (from months to weeks or days; or from months to quarters or years), view period over period comparisons, or select a specific time period of interest, e.g. "May 2009."

"The software’s advanced analytics module delivers the ability for interactive what-if scenario analysis while you watch, " says CEO Wayne Morris. "Compared to other solutions that apply a blanket proportion across every data point, myDIALS allows users to specify changes to individual data points or a number of changes across multiple dimensions and drivers all at once – either historically or into the future – returning immediate scenario results within the context of the active drill-tree." The analytics module also features sophisticated mathematical charting capabilities.

myDIALS 3.0 also enables users to determine the root cause of performance issues. "Key performance indicators (KPIs) are outcomes, and therefore not actionable in and of themselves," says Morris. "With myDIALS 3.0, decision makers can drill directly into key performance drivers (KPDs), view the relationship between KPIs and their underlying KPDs, and take action based on those specific metrics."

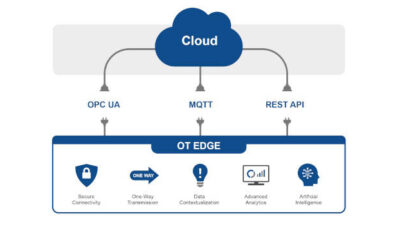

To facilitate data sharing, myDIALS has more than 35 standard connectors covering enterprise resource planning (ERP), customer relationship management (CRM) and supply chain management (SCM) systems, as well as manufacturing execution systems (MES), databases, spreadsheets and flat files.

John Colbert, vice president of research and analysis for BPM Partners, said, "Without closed-loop, continuous improvement processes taking place at all levels of the organization, a well-intended performance management plan becomes a dead-end strategy. With version 3.0, myDIALS really targets operational performance optimization, giving employees timely access to their KPIs and associated performance drivers so they may efficiently analyze performance issues and take action."

– Edited by Renee Robbins, senior editor

Control Engineering News Desk

Other HMI, Operator Interface, SCADA news from Control Engineering