Maverick Technologies, among the three 2015 System Integrators of the Year, offers advice on automation, controls, and instrumentation looking 5 years ahead, in honor of CFE Media’s 5-year anniversary. The approach to automation, networking, new people, collaboration, and cyber security will change in 2020. Advice from a system integrator follows.

Advice on automation, controls, and instrumentation looking 5 years ahead follows from Maverick Technologies, among the three 2015 System Integrators of the Year. This is part of a Control Engineering July-issue celebration of CFE Media’s 5-year anniversary. Automation, networking, new people, collaboration, and cyber security are five practical areas that will change by 2020, when working with clients, large and small, across all the industries we cover. The ways we approach these areas will be different by the time we reach 2020, although changes have already started.

1. Automation creates value

First, users have to understand how automation creates value for their company by reducing costs, improving product quality, improving production, or all of the above. Automation vendors and service providers are very good at talking about technologies, but the people running the end user companies are tired of hearing about technology and want to know how some new device or networking capability is going to have a positive impact on their bottom line. If we return to a more basic approach of using automation to solve problems rather than using automation because it’s a newer technology, it will be easier for us to put projects in the right terms. This will help convince the people who make financial decisions why they should proceed with a project, as the information will be based on hard facts and figures regarding operational improvements. We have to change the way we approach the situation and speak to executives using terms they understand, which are often financial. This is beginning to happen, and we should be more fluent in another 5 years.

2. More open networks, wireless

Second, networks will be more open and fewer devices will be wired. The walls dividing communication protocols are falling down, and by 2020 there will be hardly any left. New controllers are far more multilingual than they were in years past. It’s common for a modern programmable logic controller (PLC) to communicate using a mix of Ethernet protocols simultaneously. It might speak Profinet to one group of devices, EtherNet/IP to another, and Modbus to a third. Greater computing power makes this much simpler and allows protocol translation on the fly. At the same time, the number and variety of wireless devices will also grow. Whether Wi-Fi, ISA100, WirelessHART, or some new protocol—wireless gateways will communicate using multiple protocols, and users won’t realize the difference. If the information can get to where it needs to be, few will care about how it’s done; similar to cellular networks where users just care about performance, not the underlying mechanics.

3. New people, new problem solving needs

Third, there will be new people running our plants. By 2020 the population of baby boomers still working will have fallen off and will continue to drop rapidly. The millennials taking their places will not be preoccupied with technology, but rather its use. There will of course be exceptions, but in general, millennials want information that helps them solve problems, and they aren’t as concerned as their predecessors about the technical underpinnings.

4. More collaboration

Fourth, the new generation of workers is going to want more information, different kinds of information, and information in different forms than older workers. Millennials trust technology and what it tells them. Baby boomers generally have always had an innate skepticism of technology, and this new generation does not share it to the same extent. Millennials are more collaborative by nature, and they are more used to the idea that collaboration does not require everyone to be in the same place. Just as several people can be in different places and all still play the same video game, operators can be in different locations and control the same plant. Making this work depends on getting all the information to all the people that need it in near real-time. By 2020, this kind of communication will be an everyday occurrence.

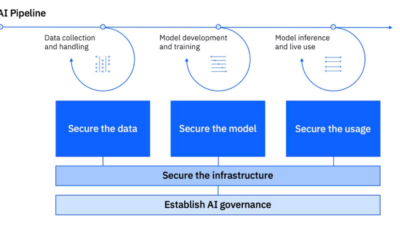

5. Built-in cyber security

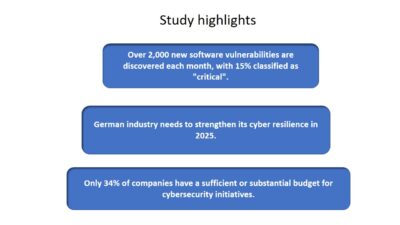

Fifth, cyber security will be built into all new infrastructure from the ground up, and "bolted on" to existing systems and networks. We keep hearing about new cyber attack vectors and methods, but defensive strategies and overall awareness of the situation among users and automation vendors is slowly beginning to increase. We’ve yet to reach the critical mass necessary to make cyber security a top priority, and it might take a major incident to get enough people’s attention, but awareness and proactive defense measures will continue to increase. No defense will ever be air-tight, but new tools are emerging to detect intruders, and by 2020 it will be much harder for cyber criminals to move around our networks without being spotted.

– Paul Galeski is CEO, Maverick Technologies; edited by Mark T. Hoske, content manager, CFE Media, Control Engineering, [email protected].

Key concepts

- Groundwork technologies for year 2020 are here today, and system integrators can help.

- Networking, communications, and collaboration will be pervasive.

- Security will be built into automation, controls, and instrumentation.

Consider this

If you don’t have a vision for enabling technologies, collaborate with a partner who can help provide a roadmap.

ONLINE extra

– Learn more about Maverick Technologies in the Global System Integrator Database.

– See more advice from Maverick Technologies in Real World Engineering tutorials.

– See additional advice on the past, present, and future of control engineering below.

Maverick Technologies is a CSIA member as of 6/30/2015