Learning Objectives

- Discover the product development challenges that are particularly suited to being solved with artificial intelligence (AI).

- R&D engineers can use self-learning models or AI to cut months of product development time.

- Engineers can use machine learning (ML) to discover new insights by exploring more operating conditions to improve product performance and quality.

Artificial Intelligence Insights

- Smart meters are used to measure energy consumption and the data collected can be enhanced using artificial intelligence (AI).

- Using machine learning (ML) creates accurate results much earlier in the product development process for problems suited to AI.

- Smart meters are being used to measure energy consumption and often involve highly complex physics such as gas fluid dynamics that require extensive simulation and physical testing to understand.

After successful applications of artificial intelligence (AI) in manufacturing or process industries, engineers sought to achieve similar benefits in product development. Teams wanted to determine if machine learning (ML) methods could be used in engineering workflows to understand and predict complex product behaviors faster and in extreme operation conditions.

Using a no-code environment on test data also helped discern what problems are suited to being solved with self-learning models. Namely those characterized by highly non-linear behavior that is hard to describe using physical equations, but that can be accurately tested.

For example, most fluid dynamics problems, whether it is natural gas mixtures flowing through a residential meter, are very difficult to resolve numerically. Tuning a computational fluid dynamics (CFD) simulation until it is accurate enough for decision-making can take months and significantly longer than testing a design on an in-facility test stand. So even though the trend goes towards using CFD more often, testing very early in the product development process is critical. AI can be applied to this early test data to faster understand what impacts the results, use the AI model to predict yet unperformed tests and even to calibrate the meter to high accuracy levels more quickly.

In short, engineers reach a faster understanding of complex system behaviors and can make faster design decisions by applying AI to product design.

While this workflow of testing and then identifying the system using machine learning (ML) afterwards might seem unorthodox, it tends to create more accurate results much earlier in the product development process for problems suited to AI, including resident and commercial gas meters and methane emission monitoring tools.

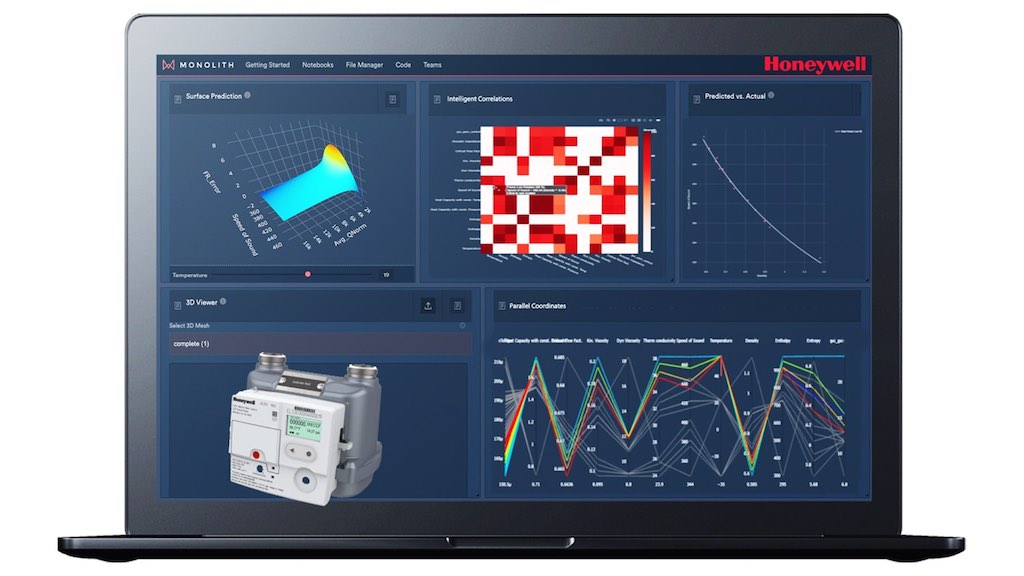

Figure 1: Designing and optimizing a residential gas meter can be an expensive and time-consuming undertaking. Using Monolith, the engineers at Honeywell can optimize their gas meters much faster using a data-driven approach. Courtesy: Honeywell

Figure 1: Designing and optimizing a residential gas meter can be an expensive and time-consuming undertaking. Using Monolith, the engineers at Honeywell can optimize their gas meters much faster using a data-driven approach. Courtesy: Honeywell

Using AI to speed up product development

The global smart meters market is expected to grow from an estimated $19.6 billion in 2021 to $30.2 billion by 2026 according to MarketsAndMarkets. Accurate measurement of gas usage has widespread benefits such as users can track and predict their own expenditures. Suppliers also can understand their client bases and provide more reliable and customized services.

The addition of pressure and temperature sensors to the residential gas flow meter has an added benefit of being able to autonomously shut down if gas-grid over-pressure is detected, enhancing safety for users.

With the energy transition, mixtures of natural gas and hydrogen will be entered into the gas grid and accurate metering of these mixtures imposes a challenge, especially for ultrasonic gas meters. This poses serious challenges for product development teams tasked with conducting the necessary tests to find the best technological solutions.

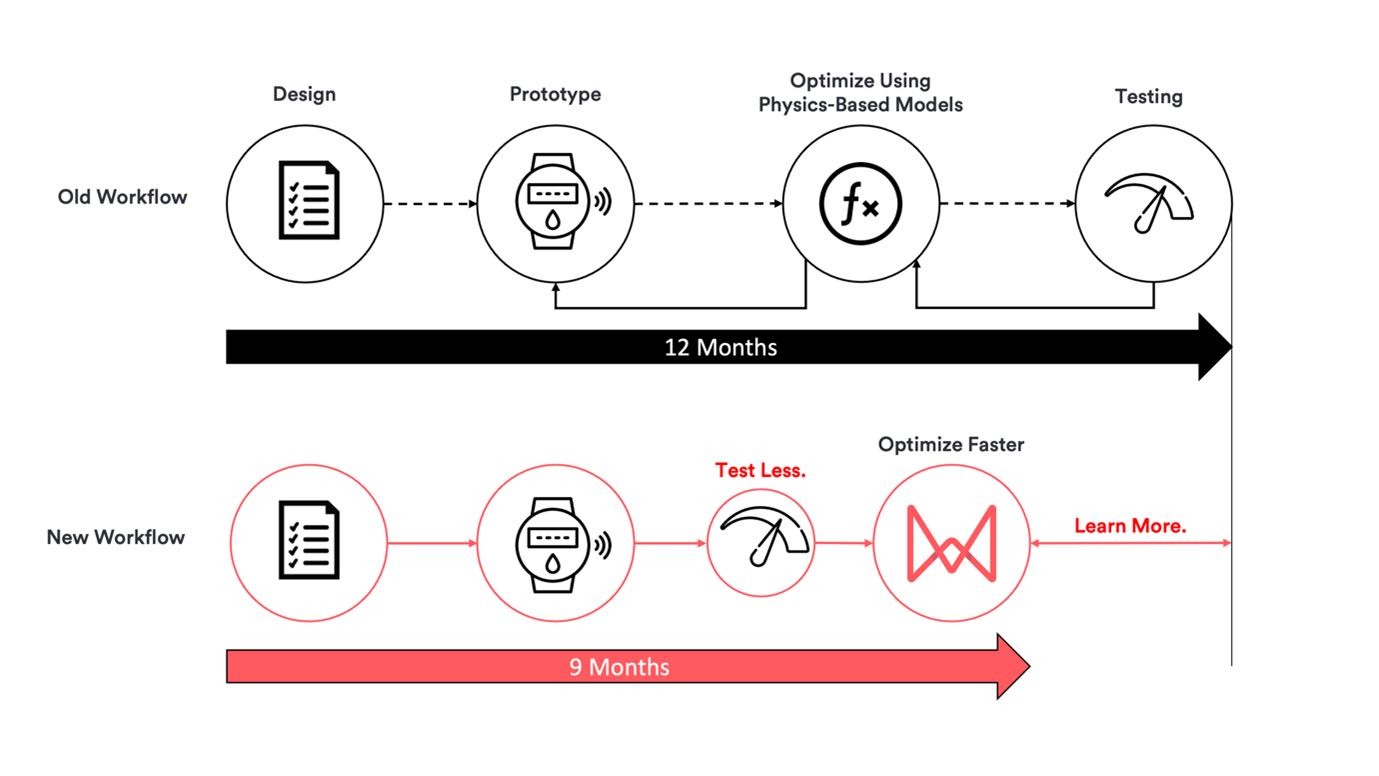

Prior to investigating AI, a traditional and familiar development process that physically and virtually tested many different product variables to arrive at a product design suitable for manufacturing. This process would often take 18 months to ensure the calibration error was below the legally required 1%. With AI, that time is reduced by 25%.

Figure 2: Top: An idealized workflow for a well understood (linear) problem where time to market and testing is minimized by solving known equations which are based on physical models. Bottom: Idealized workflow for an intractable (non-linear) physics problem that cannot be solved easily using physics-based modeling approaches but can be tested and hence modelled and calibrated using Monolith’s self-learning models. Courtesy: Honeywell

Figure 2: Top: An idealized workflow for a well understood (linear) problem where time to market and testing is minimized by solving known equations which are based on physical models. Bottom: Idealized workflow for an intractable (non-linear) physics problem that cannot be solved easily using physics-based modeling approaches but can be tested and hence modelled and calibrated using Monolith’s self-learning models. Courtesy: Honeywell

Smart AI technology for smart meters

Smart meters provide engineers more insights into their products. It’s not just during the product development process; it also can be done during quality control and in the field to optimize the smart grid. As a result, there is now a huge pool of data that development engineers can and should consider when developing new products. This requires a completely new skillset, from big data analysis to building advanced models for complex dynamic systems.

An automated solution for fugitive emissions monitoring is another perfect example of a complex issue where the stakes are high. Trying to detect the location of fugitive gas leak or process vent, and quantify it, is a deeply complicated problem because of the stochastic nature of wind direction and speed.

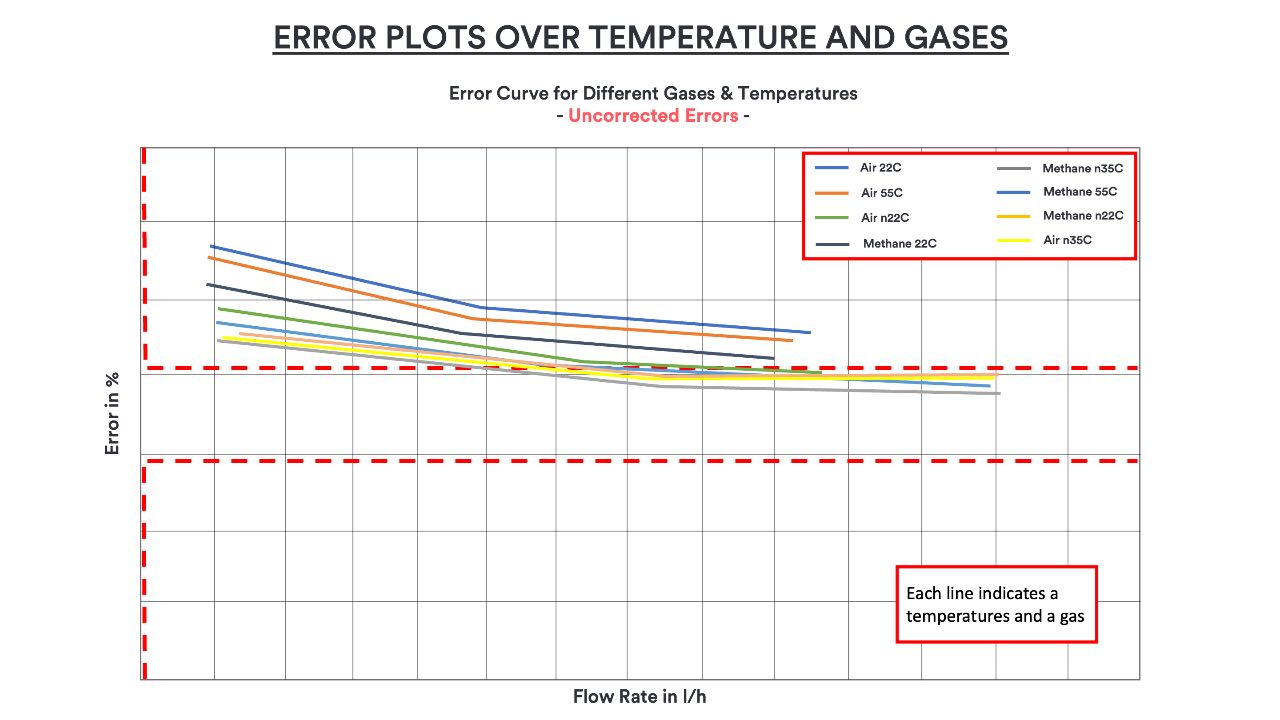

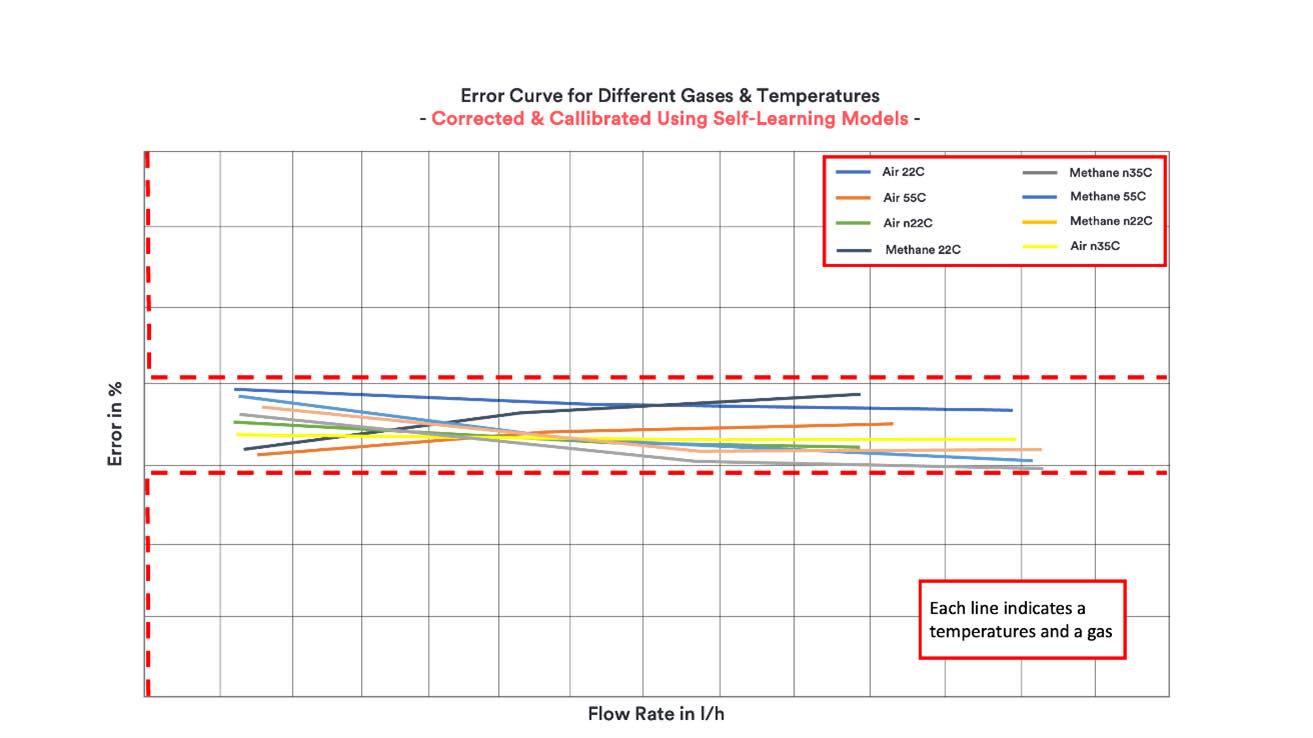

Figure 3: At the beginning of each calibration process, the accuracy of the gas meters tends to be outside the legal requirements (top image). Engineers need to calibrate the meters to fall into the red boundaries (image below). Using self-learning models, they not only fulfilled the requirements, but also achieved results much faster compared to running time-intensive, tedious and repetitive test campaigns. Courtesy: Honeywell

Figure 3: At the beginning of each calibration process, the accuracy of the gas meters tends to be outside the legal requirements (top image). Engineers need to calibrate the meters to fall into the red boundaries (image below). Using self-learning models, they not only fulfilled the requirements, but also achieved results much faster compared to running time-intensive, tedious and repetitive test campaigns. Courtesy: Honeywell

Trying to understand the physics of a complex system like this can’t be quickly or even fully represented by CFD simulation and therefore requires extensive physical testing to calibrate. In this case, engineers started building prototypes to learn from field data early in the product development process and now have advanced solutions within less than a year. Building an advanced complex industrial solution in less than year is game-changing for the process solution industry. An ML solution, unlike a heuristic model, will continue to learn and keep improving after deployment.

The increase in speed in decision-making and this ability of continuous learning helps show how self-learning engineering models may become a standard tool for engineers in the smart energy industry, and other areas with deeply complex engineering challenges.

Figure 4: Honeywell’s mission statement is to make a difference in everything they do. The company is known for its wide range of products that create safety and convenience for people around the world. Courtesy: Honeywell

Figure 4: Honeywell’s mission statement is to make a difference in everything they do. The company is known for its wide range of products that create safety and convenience for people around the world. Courtesy: Honeywell

Dr. Bas Kastelein is senior director product innovation at Honeywell Process Solutions. Dr. Richard Ahlfeld is CEO and founder of Monolith. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, [email protected].

Keywords: artificial intelligence, machine learning

CONSIDER THIS

How are you using AI and ML to help your operations?

ONLINE