Professional industry knowledge and experience must be transferred into algorithmic constraints to ensure that artificial intelligence models align with real-world requirements. This is the greatest “hidden barrier” for non-industrial background companies applying industrial AI.

Improving industrial AI insights

- Understand why industrial artificial intelligence (AI) software is moving slowly?

- Learn how industrial data can help more effective use of industrial AI, as explored by Control Engineering China and SUPCON.

- Explore how the SUPCON organization can help advance industrial AI applications.

The global manufacturing industry’s attention is focused on artificial intelligence (AI), hoping that this technological revolution can break through efficiency bottlenecks and reshape the industrial landscape. Industrial AI presents two fragmented sides. One is the hot scene driven by capital. The other is a perplexed gaze of engineers in industrial enterprises. Why is industrial AI implementation progressing slowly?

Essential characteristics of industrial AI, four pillars

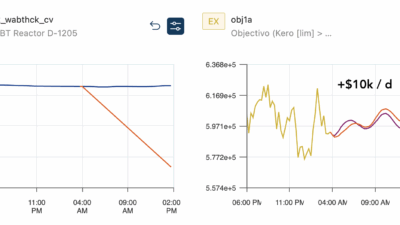

The gap between the “ideal and reality” of industrial AI largely stems from essential differences from commercial AI, which is rapidly applied and constantly breaking boundaries. Wang Kuanxin, an industrial AI expert at SUPCON, pointed out that the data format in the industrial field, commonly known as the B-end, is fundamentally different from the C-end. The development of industrial AI must be based on massive industrial data, especially data with strong temporal characteristics, while deeply integrating industry knowledge, experience and physical mechanisms, to find a unique innovation path. [SUPCON partners with leading smart industry enterprises to deliver AI-powered automation and control solutions to drive industrial efficiency, intelligence and sustainability.]

“Currently, many large models from the commercial field simply have been migrated to the industrial field, mainly focusing on surface applications, such as information acquisition and question-and-answer knowledge. While these applications have improved the efficiency of knowledge acquisition, they have yet to address core industrial pain points, such as intelligent control, quality improvement and efficiency enhancement, and energy conservation and emissions reduction,” Wang Kuanxin said.

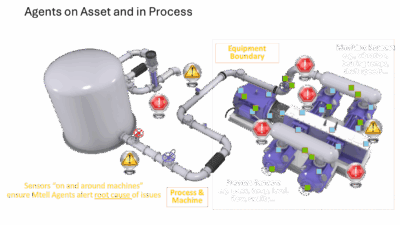

Algorithms, computing power and data are widely recognized as the three core elements of AI. However, for industrial AI, the importance of the “scenario” dimension has been elevated to an unprecedented level, forming the “four pillars” that drive implementation alongside the first three elements. This stems from a fundamental characteristic of industrial applications: high fragmentation and differentiation. Different industries, and even different sub-sectors within the same industry, have vastly different production processes, core physical/chemical mechanisms, production equipment, and pain points that need to be addressed. It is precisely this profound scenario specificity that severely constrains the scalable replication and rapid adoption of industrial AI technology. Unlike commercial AI solutions, which can be relatively generic and deployed quickly, industrial AI faces the challenge of “customization” in each sub-sector and even specific production lines. Attempting to solve all industrial problems with a one generic model or platform is simply not feasible.

Breaking the double shackles of industrial data

The foundation for developing industrial AI lies in data, a principle that is no different from the commercial sector. However, the unique nature and high sensitivity of industrial data have erected insurmountable barriers to its sharing and application.

Wang Kuanxin said, “Industrial data is highly closed, with low levels of sharing, and typically remains in a relatively confidential state.”

This characteristic stems from the nature of industrial production. Unlike the publicly available datasets used to train commercial large models, industrial data often contains a company’s core production and operational secrets and intellectual property, and involves complex compliance issues. This not only makes data sharing between companies extremely difficult, but even within the same group, different subsidiaries are often “clearly separated” due to confidentiality barriers.

The phenomenon of data silos undoubtedly seriously restricts the effective training of industrial AI models, but the demand for intellectual property protection by enterprises is understandable. How to balance confidentiality requirements and technological development? The strategy of SUPCON is a multi-pronged approach technically, establish a sound data confidentiality and desensitization mechanism to provide security guarantees for data assets.

Enterprises with strict data control can explore the “data does not leave the factory” mode, deploy private domain large models locally within the enterprise and accumulate reusable experience for the enterprise while operating in compliance. Of course, in the long run, promoting the rational sharing of industrial data remains an important direction.

In addition, the challenges of industrial data acquisition are reflected in its diverse types (operations, equipment, quality, simulation and other dimensions), multiple sources (enterprise facilities, laboratories, design institutes, etc.), and data validity. The latter requires powerful data standards and algorithmic technologies for cleaning and enhancement.

Algorithms with industry knowledge are more important than computing power

For technical architecture and core algorithms, industrial AI also demonstrates its uniqueness. While the outside world focuses on the “computing power competition” of AI, the industrial sector has different priorities.

Compared to commercial scenarios, industrial data is significantly smaller in scale, so the reliance on computational power is not as high. However, the unique characteristics of industrial data—such as temporal nature, low signal-to-noise ratio and multi-scale—dictate that industrial AI algorithms must be deeply integrated with industry knowledge. Otherwise, it would be difficult to uncover the intrinsic connections and potential value within industrial data.

For example, Wang Kuanxin said that in process industries, the “implicit knowledge” such as the physical mechanisms of equipment operation and the laws of chemical reactions is beyond the grasp of general AI models. In discrete industries where most processes are “visible and tangible,” this implicit knowledge must be analyzed and explored through process simulation, further raising the professional barriers for addressing such issues.

Hidden barrier: Industrial sector knowledge is required

Therefore, relying solely on data training is not feasible in the industrial sector. It is essential to translate professional industry knowledge and experience into algorithmic constraints to ensure that models align with real-world requirements. This is the greatest “hidden barrier” for non-industrial background companies entering the industrial AI field. To address this challenge, it is necessary to build a technical architecture and core algorithms that are more closely aligned with industrial characteristics.

The mainstream model for the future development of industrial AI is likely to be that industrial AI manufacturers provide AI tools and platforms that carry core capabilities, while industry users who directly grasp scenarios and data, or their affiliated data companies, can use these platforms and tools to solve practical problems for their specific scenarios.

Stone Shi is executive editor-in-chief, Control Engineering China. Edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

KEYWORDS

Industrial AI, process manufacturing AI, discrete manufacturing AI

CONSIDER THIS

Are your AI efforts delivering industry-level expertise?

ONLINE

https://www.controleng.com/international-editions

More from Control Engineering on AI is available.