Is now the time to get a collaborative robot? Using collaborative robot in diverse industrial applications increases productivity, quality and employee retention while lowering risk of repetitive injury.

Collaborative robot industrial insights

- Collaborative robots are not expensive, can be applied to smaller industrial production runs and create more jobs because of higher productivity, according to an IMTS 2024 session, “Is now the time to get a collaborative robot?”

- Collaborative robot application examples demonstrate advantages and highlight the need for risk assessments.

- More collaborative robots (said to be the fastest-growing robot segment) can benefit expected tighter labor markets and more anticipated U.S. manufacturing opportunities.

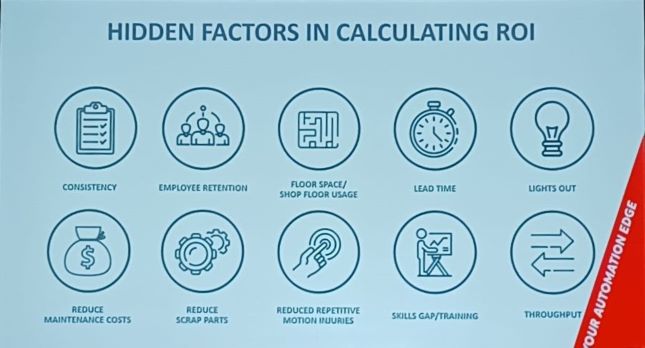

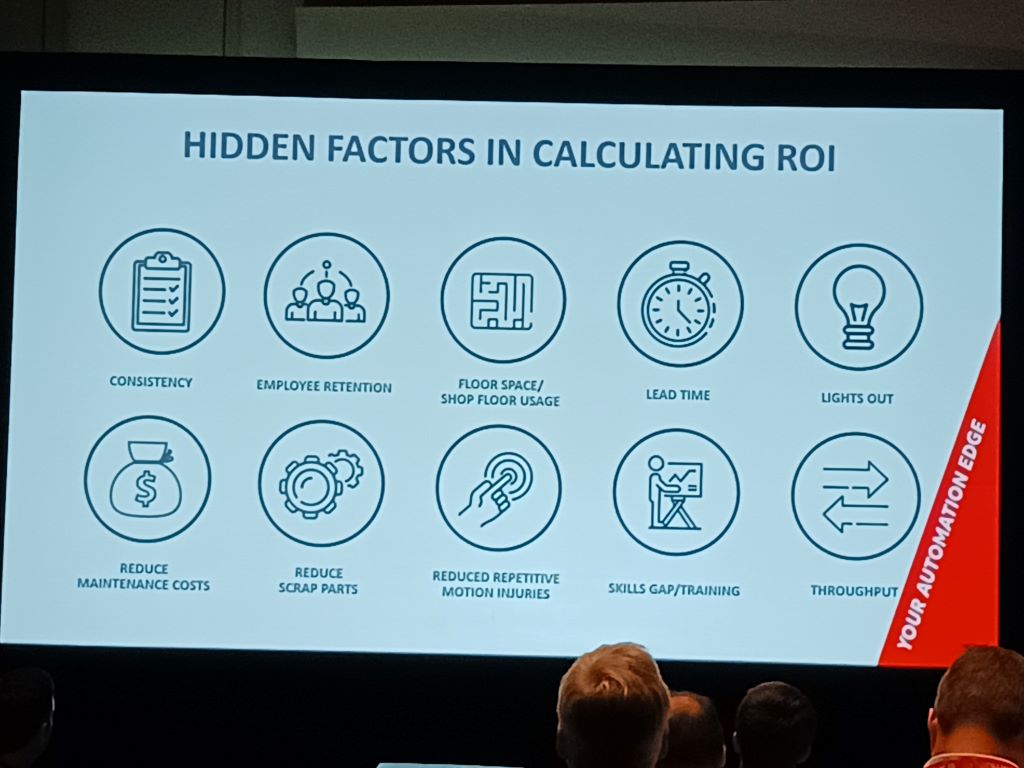

Dispelling three common myths about collaborative robots for industrial applications, Steve Alexander, Acieta vice president of Wisconsin operations and standard products, answered the question posed in the title of his IMTS presentation, “Is now the time to get a cobot?” The answer increasingly is “Yes” for a broadening array of industrial applications, to increase productivity and throughput, consistency, employee retention, floor space, lead time, automated operations, and reduce maintenance costs, reduce scrap parts, reduce repetitive motion injuries, while improving skills gap and training challenges. Many of these are hidden or unquantified factors (Figure 1) when calculating return on investment in a collaborative robot, he said.

Collaborative robots: Not expensive, not only for high-count production, more jobs

Three robot myths are:

-

Robots are expensive and hard to justify during uncertain times: Myth. Hiring and retaining talent, especially for repetitive jobs that can be prone to injury, can be difficult and costly. Cost of onboarding can be 30% the first year of salary.

-

Automation is only for high-production jobs: Myth. Technology has simplified the process of automation, especially with collaborative robots, making small part runs more efficient and setup faster. Using automation is easier.

-

Robots steal jobs: Myth. “I don’t know why we still hear this,” Alexander said. Companies using robots find they need more people to handle increased product production created by robot use. “Robots create a virtuous circle of investment and growth,” he said, showing an A3 information matching increased industrial robot shipments with decreasing U.S. unemployment.

Collaborative robot productivity, application examples

Alexander also provided multiple examples of higher customer productivity, including using one collaborative robot for multiple tasks (Figure 2). With low unemployment, Hytrol needed automation to help meet customer demands. In the application, a robot picked a raw sheet of metal, picked components, moved the product to a bending cell, then to a welding cell and the finished product exits the work area.

By combining six work cells into one (Figure 3), the automated application cut floor space by 80% and reduced human footsteps and forklift traffic, lowering risk. It added 50% capacity, lowered lead time and increased marketplace competitiveness, Alexander said.

Is my application good for a collaborative robot?

Robots, especially collaborative robots, are more flexible and can handle smaller jobs with higher variability effectively. Alexander said he’s often asked, “Is my application a good fit for a cobot?”

Robotic applications can include pick and place, packaging, palletizing, machine tending, material handling, fabrication and welding.

In load and unload CNC machine tool collaborative robot applications, Alexander cited increases of 82% to 19.3 parts per hour, 66% to 21.3 parts per hour and 96% to 72 parts per hour.

Bundles of automation created for specific uses include:

-

A flexible collaborative welding cell to help machine shops and fabrication shops is useful for rework and even small batch runs. (See video.) Skilled welders welcome robotic welding additions for redundant, lower value work, saving welding time and expertise for more skilled work.

-

Standard collaborative machine tool cell can help with machine tending, gauge tending, saw tending and coordinate measuring machine (CMM) tending.

-

Standard collaborative expandable cell can with polishing, material removal, sanding and edge breaks.

Collaborative robots are easier to program, often by teaching the robot where it needs to go by physically moving the robot arm as needed.

He described an application where, two robots grab parts, a press joins two parts. Light curtains are needed separating the press from the collaborative robot and human area. Some robots can be taken out of collaborative mode and go faster.

Because force and speed limits the speed to 1000mm/sec in collaborative mode, a human can be faster. However, a collaborative robot’s efficiency was higher, with no breaks, providing higher throughput, a 36% productivity increase compared to a human, lowering risk of repetitive injury and boredom.

Explaining how to justify purchase of a collaborative robot, Alexander showed applications, quantified labor savings and specific applications, including a collaborative robot welding workcell. Applications vary, but most collaborative robot installations have return on investment (ROI) of 18 to 24 months.

Collaborative robots may require safety measures depending on applications

While collaborative robots may be considered because they are force and speed limited to lower risk of human injury, cobots still may cause harm in certain applications requiring protection for humans, their environment and themselves. Always perform a risk assessment when using robots because even with collaborative robots, applications may require additional safety protections, such as those with:

Extremely short cycle times, sharp objects, sharp edges (such as sheet metal), hot parts, height of motion (avoid human heads), grippers (Will they sense and stop in case of a human finger?), other clamping devices or pinch points that could harm and peripheral equipment (other equipment in the application or work area may not include safety measures designed into collaborative robots).

More robots are needed: Tighter labor, more opportunities

Two additional reasons Alexander cited justify collaborative robots:

-

U.S. gross domestic product is expected to increase 40% in the next 10 years, with an expected 1% labor pool increase during the same period, likely to increase industrial skills-gap challenges.

-

China demographics suggest 150 million fewer people in labor the Chinese labor force in the next 10 years, which creates opportunities for reshoring additional industrial production to the U.S.