Selecting among technology options in a motion-control application often comes with levels of complexity, especially when dealing with multiple axes. Explore five automation advantages of multi-axis servo drives.

Multi-axis servo drives, motion-control design insights

- Selecting among technology options in a motion-control or machine design application often comes with levels of complexity.

- Multi-axis servo drives can help limit that complexity and increase performance in space, synchronization, energy, scalability and data handling.

- Explore five automation advantages of multi-axis servo drives with a table and four figures.

Multi-axis servo drives started gaining popularity in the early 1990s, and since then, more technological advancements have been made to make these devices even more powerful. There is an immense upside in the differences in having multiple axes in one simple-to-use package rather than multiple single packaged drives. Selecting among options in a motion-control or machine design application often comes with levels of complexity, especially when dealing with multiple axes. Multi-axis servo drives can help limit that complexity and increase performance in space, synchronization, energy, scalability and data handling aspects.

Space efficiency of multi-axis servo drives

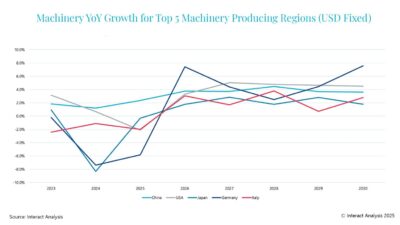

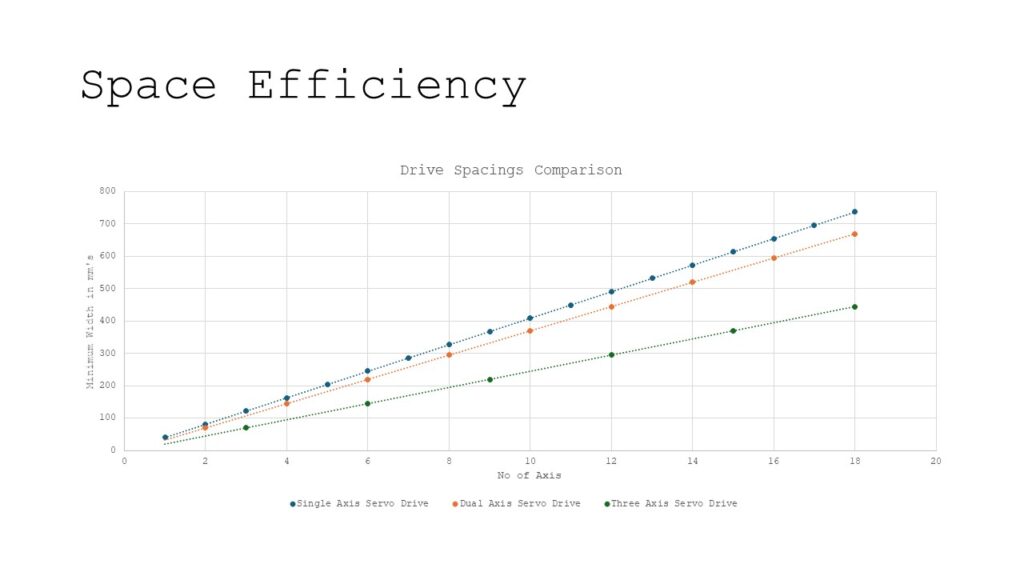

1. Space is a vital characteristic to consider in designing panels for servo applications. For a multi-axis system, the panel must contain fans and have strict spacing conditions based on safety standards. With increasingly complex systems with multiple connections and routing points, even saving the smallest amount of space can become crucial. For example, one three-axis drive is 70mm in width. To compare, the smaller models of a single-axis drive are 40mm wide with 1mm of required spacing. By driving three axes with the identical power-rated drives, a motion-control application or machine designer can save 52mm or 57% of total width by using multi-axis drives. This idea will save exponentially more space for applications with more axes. The table shows how this occurs.

Cost savings (wiring) of multi-axis servo drives

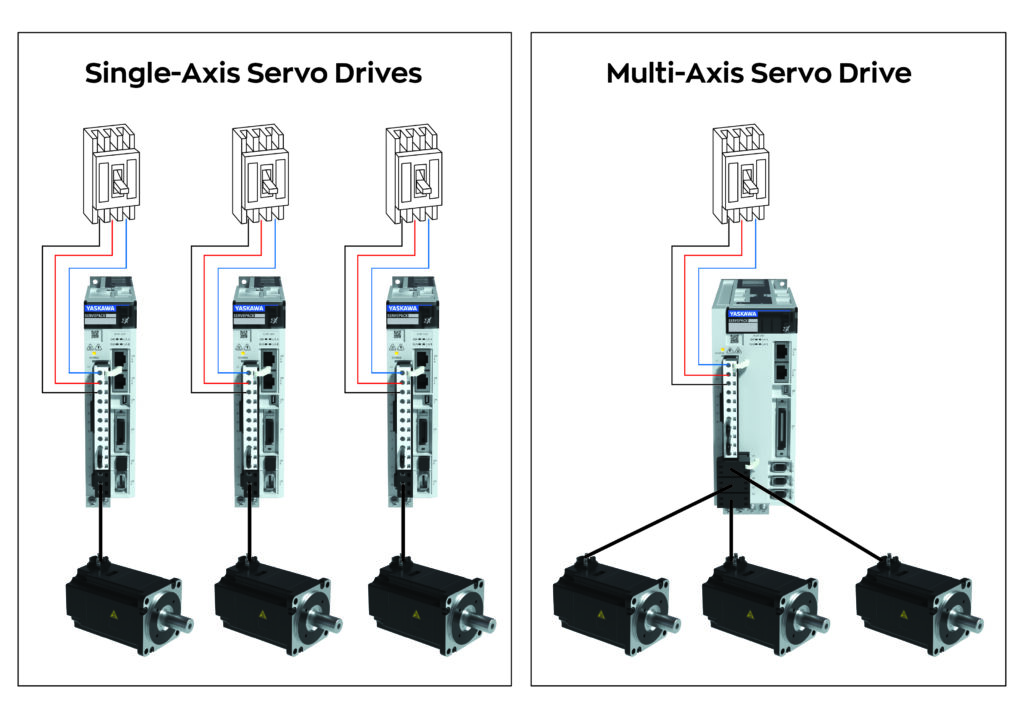

2. Consolidating multiple axes into one servo drive helps with panel spacing. Building a panel can become tedious work when following all standards, so space becomes a key issue when designing. Power wiring becomes simpler because multi-axis servo drives often share a common DC bus. Input power circuit protection becomes simpler because of that common bus.

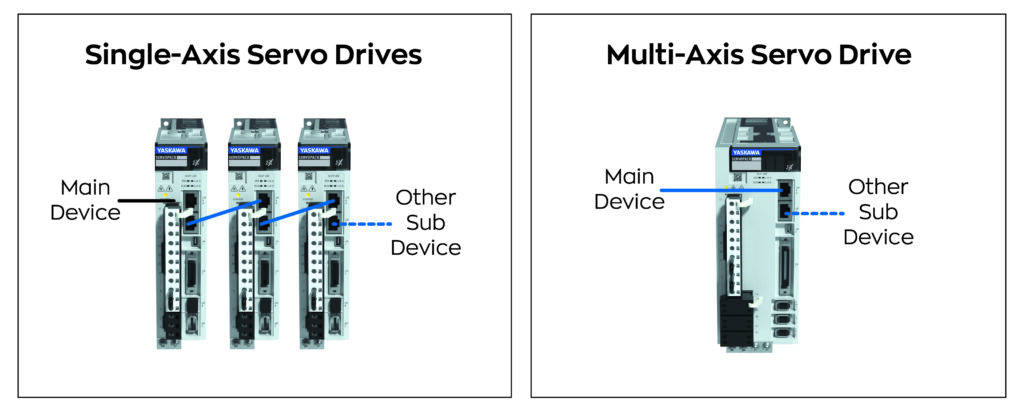

A panel designer does not need to provide circuit protection for multiple power lines to single-axis servo drives. Controller-to-drive communications connections are simpler since multi-axis drives share one communication line, as opposed to the usual daisy-chained lines in multiple single-axis systems. Although minor, in multi-axis servo drives, the motor power and encoder connections are condensed closer together, so the cables from each motor can be routed closer together and more organized.

The total space improvements save costs due to fewer cables and the overall cost of the servo drives.

Communication and data handling in multi-axis servo drives

3. Along with spacing improvements, programming multi-axis drives has advantages. As stated before, the communication connections are greatly simplified when using a multi-axis drive. This goes hand in hand with how the drives are programmed. There is only one device, but each axis can be controlled and interfaced with much more simplicity.

Firmware updates to drives can often sideline an application, especially in the design and testing phase. Depending on where the servo drives are located, it can be tough to get cables to reach the correct connectors. With a multi-axis servo drive, you can significantly reduce the amount of device maintenance required.

Energy efficiency of multi-axis servo drives

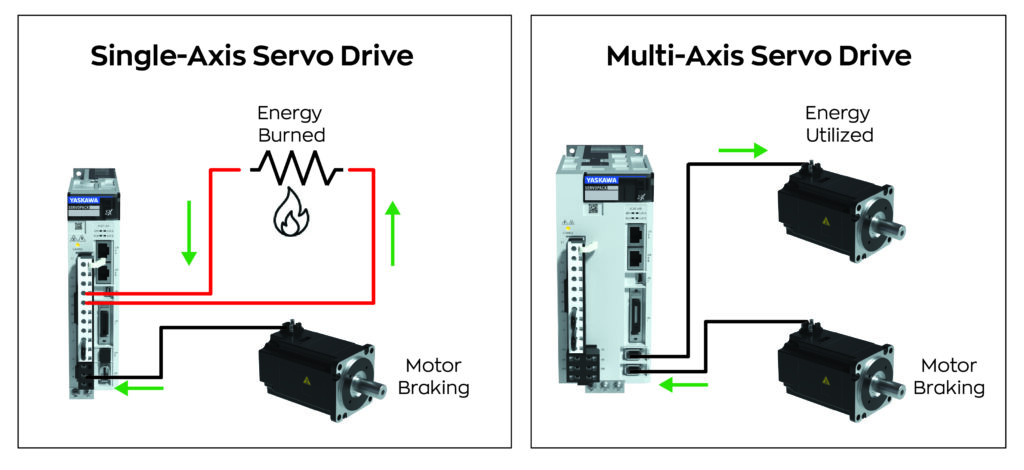

4. Energy efficiency can be improved in applications that use multiple axes. It is important to note that multi-axis drives share a common DC bus, which is crucial for energy dissipation. Take an application that runs two motors simultaneously with opposite motion profiles, where one motor accelerates while the other is decelerating. With a multi-axis drive, energy from the motor that decelerates can be used for the accelerating motor due to the common DC bus. There is no common DC bus with two single-axis servo drives unless extra modifications are made to the drives. So, all the energy that comes from a decelerating motor is just wasted. If an application constantly has situations like this, using a multi-axis drive can drastically save energy, which saves money. Figure 3 shows a basic flow of energy when this happens.

In addition, multi-axis servo drives are more efficient, avoiding some power loss. Although small, the differences in power loss can save substantial amounts of energy and money in the long run.

Scalability and modularity of multi-axis servo drives

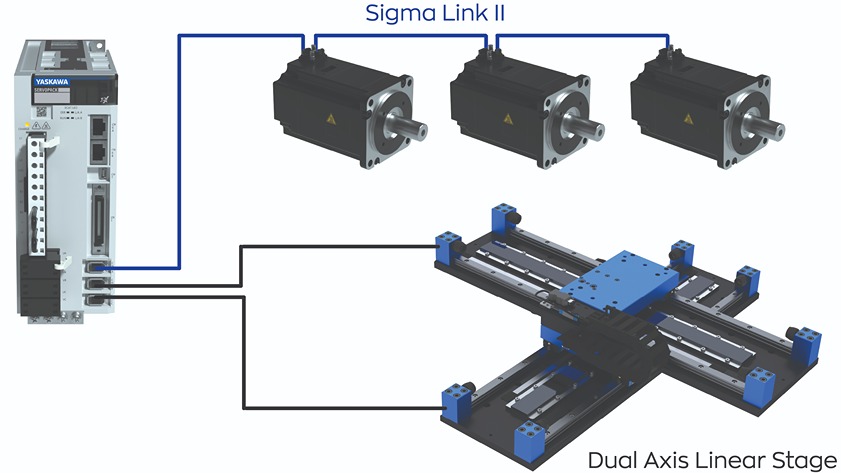

5. Scaling axes on an application is possible when using multi-axis drives. You can drive X, Y and Z axes with one device. More options are available when using something like technologies that enable connection of multiple motors to a chained encoder line. Changing node addresses allows each motor in that line to be individually controlled. A application designer can place up to three motors in a line in specific places to achieve an application. With many available setups and configurations available, the possibilities of applications on one device are numerous.

Applications that could benefit from using multi-axis servo drives include computer numerical control (CNC) machines, simple robotics, packaging machines, printing presses, gantry systems and textile machines. Any application that requires moving through three-dimensional space, requires synchronized joint motion, or precise timing and control between multiple points will require the use of multiple axes. As discussed, many advantages exist in selecting multi-axis drives over single-axis drives.

Roman Skorupa, product engineer, Yaskawa. Edited by Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

KEYWORDS

Multi-axis servo drives, comparisons with single-axis servo drives

CONSIDER THIS

How are you simplifying your multi-axis motion control application designs?

ONLINE

Get more help with motors, drives and motion control on these Control Engineering pages.

https://www.controleng.com/motors-drives