Automate 2024: ROS-I tools and resources make open-source more accessible to industry through collaboration, said Matthew Robinson at Automate 2024 by the Association for Advancing Automation (A3). Video: 3 take-aways about open-source robotics. See also video clips, photos.

Learning Objectives

- Understand how the SwRI and ROS-Industrial SWORD tool helps robot modeling, motion planning.

- Explore the ROS-Industrial technology vision and the benefits of open-source robotics.

- ROS-I projects include resurfacing airplanes, communications, motion planning and robotic grinding and blending milestones.

Automate 2024: ROS-I open-source robotics insights

-

The SWORD tool from ROS-Industrial and Southwest Research Institute (SwRI) helps robot modeling and motion planning.

-

The ROS-Industrial technology vision and collaboration brings benefits to plant-floor applications of open-source robotics.

-

ROS-I projects include resurfacing airplanes, communications, motion planning and robotic blending (metal surface grinding and smoothing).

Open Robotic Operating System (ROS) industrial capabilities are expanding through collaboration, tools and training for easier programming, integration and communication among robots from different manufacturers, according to Matthew Robinson, ROS-Industrial Consortium Americas program manager, Southwest Research Institute (SwRI). Robinson spoke at Automate 2024 by A3, the Association for Advancing Automation, in Chicago. The session, “Developing a high-mix capability through open-source collaborative initiatives,” is very exciting for industrial robotics, said Robinson before the session, about helping advanced robotics integrate more effectively.

New: SWORD helps robot modeling, motion planning

The ROS-Industrial Consortium SWORD (SwRI workbench for offline robotics) is a FreeCAD plugin that integrates robotic capabilities into a cross-platform environment. Using modeling, SWORD can help create or import a robot CAD model with fixtures and end-of-arm tooling, for manipulation and control of the robot model, simulated movement, optimization of motion planning to predict and avoid movement collisions.

“Five years ago this was a dream. It’s happening now,” Robinson said.

In describing SWORD, Robinson said setting up ROS systems in C++ can be painful. SWORD makes it easier, taking a configuration, rather than programming, approach. Alpha version became available in January 2024, and new features on way include export to robot-native files, CAD to path, integration with Noether, raster planning, meta-planning integration and remote TCP. Learn more at about ROS-I’s SWORD at https://sword.swri.org.

Technology vision, benefits of open-source robotics

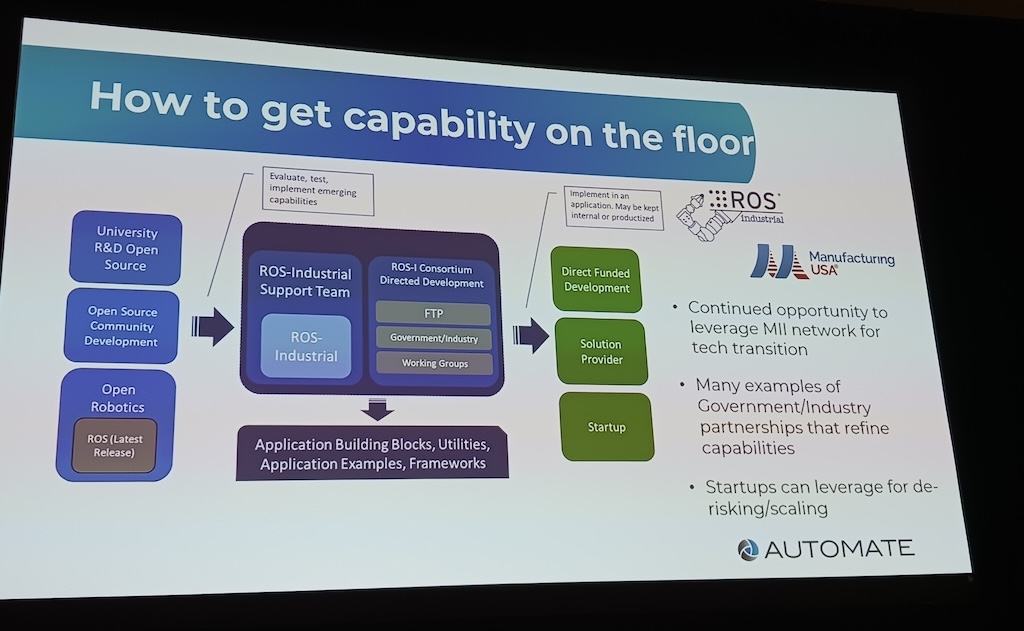

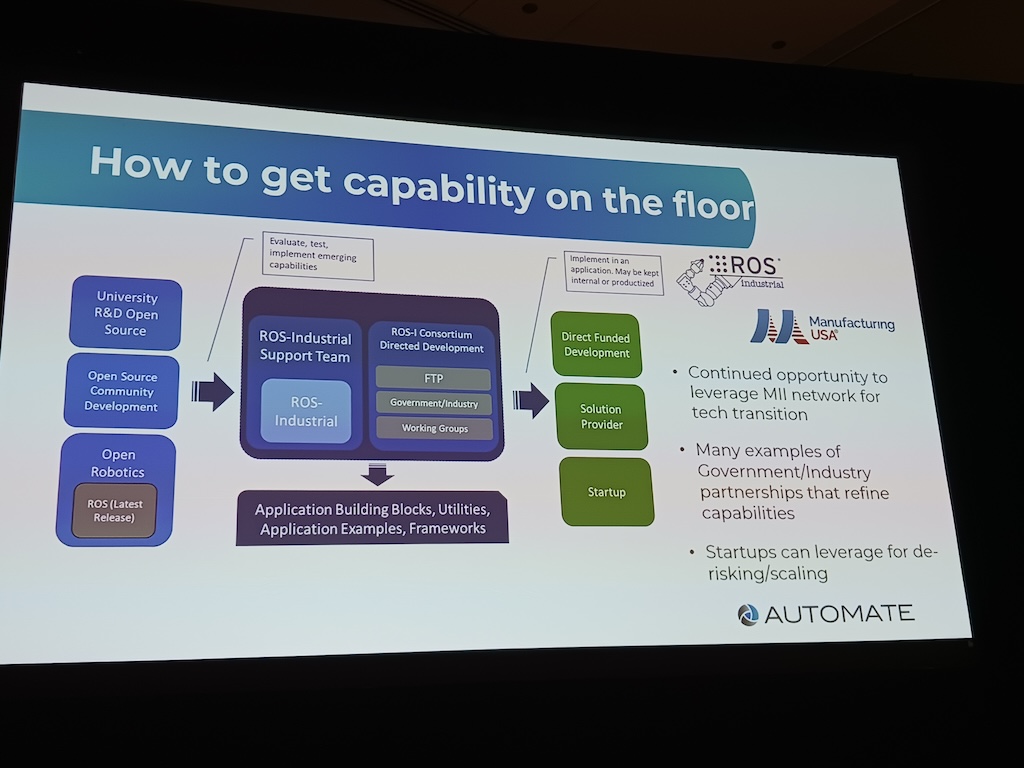

The technology vision of open-source robotics is supported by industry, Robinson explained, because “ROS-Industrial Consortium acts as an ecosystem where different players — end users, equipment providers, system integrators, institutes of research and training partners — come together to advance and proliferate open-source robotics.” ROS, maintained by the Open Source Robotics Foundation, is less an operating system and more a middleware framework of reusable software components that enables communications among disparate software systems, Robinson said. It has more than 1 million software downloads per month.

Other ROS-I capabilities and modules include cartesian tolerance waypoints, coordinated motion, robotic blending milestone 5, REACH (robot evaluation and comparison heuristic, to visualize and evaluate robotic system reach capability for a given workpiece: where to place the robot) and feature segmentation. ROS-Industrial Consortium began in 2013 to help resolve industrial automation challenges with open-source software. Coding is in Microsoft Windows or Linux, using C++. Best practices for documented modular software architectures are encouraged, Robinson said.

SwRI: robotics, computing, networking, automotive testing, energy and environmental research

SwRI is an independent nonprofit organization in San Antonio, Texas, whose reach extends beyond robotics, including the High Reliability Systems Laboratory to develop computing and network solutions for spacecraft, automotive testing, as well as energy and environmental research.

ROS-I projects: Resurfacing airplanes, communications, applied motion

The largest ROS-I physical project is a mobile manipulator for Boeing 737 fuselage resurfacing.

In the robotics market, according to Robinson citing A3, the largest growth is in machine vision and in material handling.

ROS-I foundational libraries interface with industrial hardware via software. Functionality provided includes utilities for calibration in industrial settings, development interfaces, application toolsets, bridges and interoperability bridges, Robinson said. Fanuc and Kuka are among companies with a ROS 2.0 interface, which began in 2019, providing multi-axis robot motion planning.

“We work with ROS-I OEMs to ensure interface support so the open-source code doesn’t become dated and dysfunctional. An abstraction layer make interfacing easier,” he said. Robinson knows the need for supportable architecture, previously having worked 14 years at Caterpillar. Code that isn’t documented and modular is more difficult to work with over time, especially after the writer has stepped away, he said. The ROS-I continues to support ROS1 systems as ROS2 is advanced at deployed with tools, hardware interfaces and applications as part of a global community.

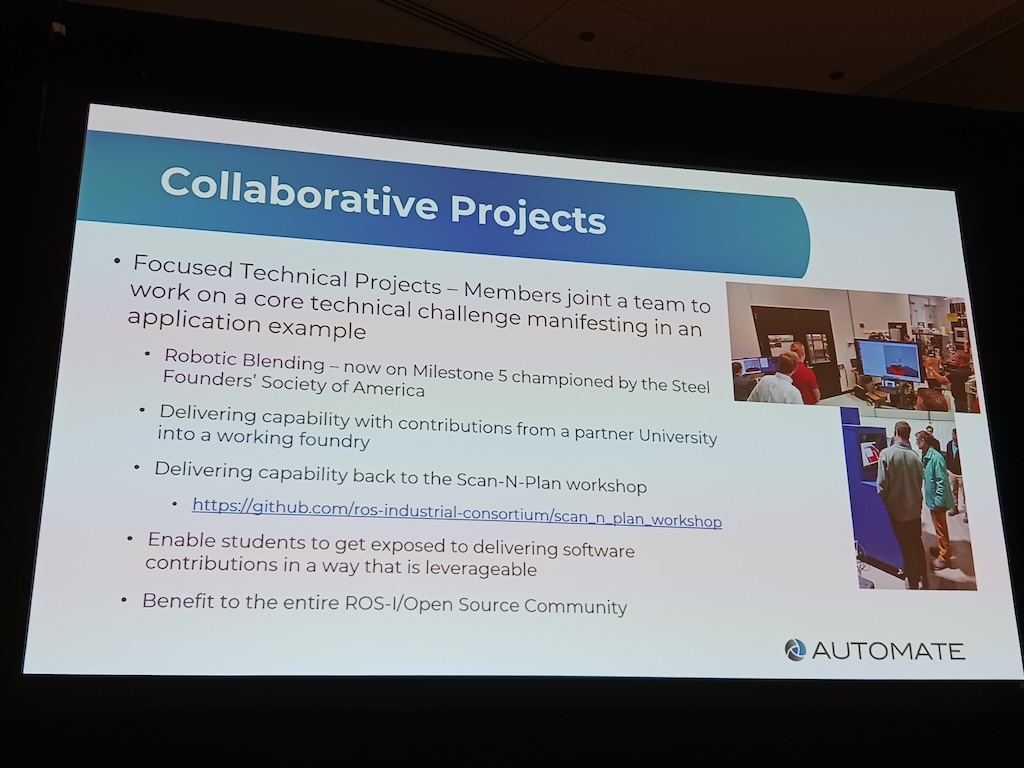

Networking with other industry groups fosters collaboration, including training at Automate in 2023, and with AWS, Rounders’ Society of Americas, Coaters’ Association, Remanufacturing Industries Council and Manufacturing Innovation Institutes. ROS-I education includes workshops, training, reference resources and example applications.

ROS-I listens to stakeholders, Robinson said, to improve its tools, including efforts on SWORD, REACH, coordinated motion, optimization-based motion planning and improvements to tool path planning.

ROS-Industrial: Robotic grinding, blending milestones 4, 5

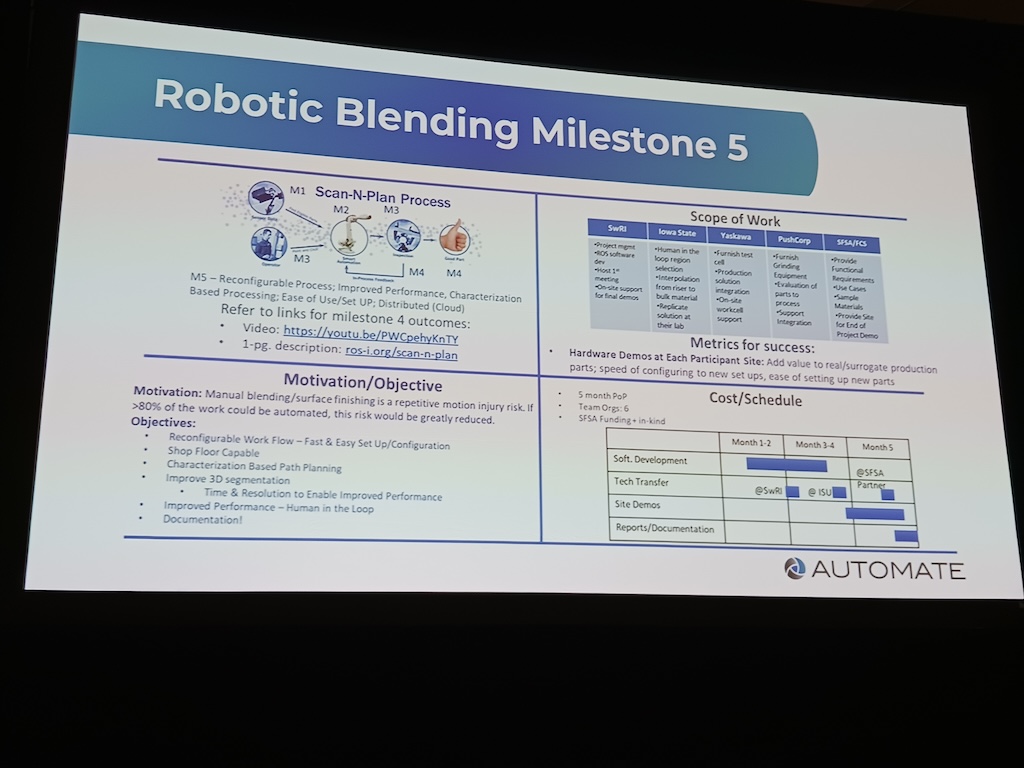

Robinson talked about demonstrations marking milestones in robotic blending, championed by the Steel Founders’ Society of America. Milestone 4 in the project included a technology demonstration in a low-lot high mix manufacturing site using industrial grade sensor (IDS Ensenso N35) for automated part inspection. It has opportunity for 73% return on investment based on overall part processing are efficiency improvements via reduction in variable labor, Robinson said. Work has helped enable intuitive, agile automation for high-mix foundry environment, meaning greater ease of use and robustness, ability to handle more parts with less teach pendant programming and less reliance on part-specific tooling, Robinson said.

Milestone 5, with Steel Founders’ Society of America (SFSA) as the champion with involvement from Yaskawa, PushCorp, SwRI, Iowa State University and Fisher Cast Steel, had its final demonstration March 7 at an Ohio foundry. Motivation was to reduce by more than 80% the work of manual blending and surface finishing of parts (video shows robotic grinding), greatly reducing risk of repetitive injuries, while keeping a human in the loop. The project contributed to ROS-I efforts in sub-mesh visualization, dynamic scan trajectory execution, additional Python notes and Docker.

Robinson said each project, with learning and teaching along the way, aims to put advancements back into open-source code and other ROS-I offerings, such as plug-ins, so work gets improved upon. “We use MIT-styled licensing so the rising tide helps all boats.”

Mark T. Hoske, editor-in-chief, Control Engineering, WTWH Media, [email protected].

KEYWORDS

Automate 2024, ROS-Industrial, open-source robotics

CONSIDER THIS

What ROS-Industrial tools can help your robotic efficiency?