Which devices to use? A multi-tasking controller combines functions of a PC-based software controller with visualization, PC applications, and input/output connections. Combining a scalable human-machine interface (HMI) system, supervisory control and data acquisition, and other functions can add edge functionality.

Does an application need a modern programmable logic controller (PLC) or an edge device? Attributes of each can help select the appropriate architecture for an application.

Integrated PC/PLC

A PLC brings about a vision of simple, proprietary device running a dedicated ladder logic program performing basic automation tasks, previously left to hard wired relays. Controllers are expected to be high performing, robust and modular, and have onboard high-level communications, standard/open connectivity, and simple integration with PC applications and model-based simulation. Some controllers have all these features and can “multi-task,” acting as a PLC, human-machine interface (HMI) and a standard PC in one compact device.

A modern multi-tasking controller combines the functions of a PC-based software controller with visualization (an HMI), PC applications (Microsoft Windows or Linux), and central input/output (I/O) connections in one compact device. Such controllers, with pre-installed and preconfigured PLC software controller for the control program, operates independently of Microsoft Windows (doesn’t run on Windows), ensuring high system availability. This enables the controller’s rapid start-up and supports Windows updates and reboot during ongoing operations. Failure of Microsoft Windows does not have an impact on the controller.

Applications for these optimized controllers include series machine manufacturing and for machines with distributed architectures. Such modular controllers minimize space and can be accommodated in compact control boxes on the machine, improving the cost-performance ratio. An industrial flat panel connected through the graphics interface can provide visualization, optionally with multitouch functionality. Since the PC is built in, no separate PCs are required. For commissioning, mouse and keyboard can be connected via standard onboard USB interfaces. At the same time, the gigabit Ethernet interfaces support high-performance connection to higher-level networks.

Many applications may benefit from a multi-tasking controller architecture. Compact, multi-tasking controllers are also expected to include standard functionality like built in safety, integrated security, built in diagnostics, and high-level motion control in one package.

Edge controller

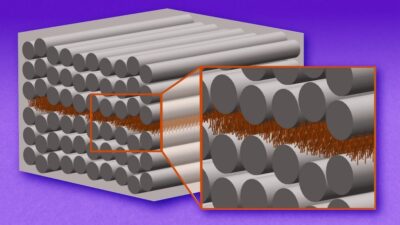

Edge devices provide a platform to run analytics, predictive maintenance and other tools that help optimize production without interfering with production itself.

An edge computing device could be an industrial PC (IPC) or the edge functionality can be integrated in the automation device like an HMI panel. This way the HMI panel fulfills both requirements, ensuring stable production while allowing for a high degree of flexibility in running new programs or tools that help increase productivity.

New production concepts for Industry 4.0 don’t rely on the International Society of Automation (ISA) automation pyramid anymore. Instead, they split production in smaller and flexible units that exchange data on many levels. This requires flexible and scalable HMI systems where the same project and screens can be used on a 7-inch HMI panel, a supervisory control and data acquisition (SCADA) system or a smartphone. The data is available in real time on any device when needed without increased programming effort.

One possible use case might be to have the HMI device controlling the machine while the edge portion of the device collects additional data for predictive maintenance or runs complex algorithms for machine optimization.

Consider the application

Of course, this combined functionality isn’t just beneficial for HMI devices. PLC modules, drives and network devices with integrated edge functionality allows for further productivity increases.

Jim Wilmot is factory automation marketing manager at Siemens Industry Inc. Bernd Raithel is director product management and marketing, Siemens Factory Automation, Siemens Industry. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media, [email protected].

KEYWORDS: Programmable logic controller, PC, HMI, edge computing

Integrated PLC-PC-HMIs help digitalization.

Edge computing can run analytics, predictive maintenance and other tools.

Rugged applications benefit from updated control architectures.

CONSIDER THIS

How will more advanced controller architectures help optimize applications?