Energy-efficient motors and variable speed drives (VSDs) can help reduce production costs through greater energy efficiency.

For sectors that are very dependent on energy supply, fluctuations in price and availability have the potential to cause major supply chain disruption – particularly due to price rises for carbon dioxide.

Unfortunately, the renewable energy transition and Europe’s reliance on natural gas imports is making the continent’s energy supply increasingly volatile. Therefore, making production facilities as energy efficient as possible is essential and many of the most energy-consuming processes involve electric motors.

Managing existing motors

The first step to improving energy efficiency is taking stock of the status of existing motors – many of which could be oversized. Motors in applications like fans and pumps traditionally run at a partial load, using a valve, brake or throttle which means that motors could be working harder than necessary, and by using mechanical speed control energy is wasted.

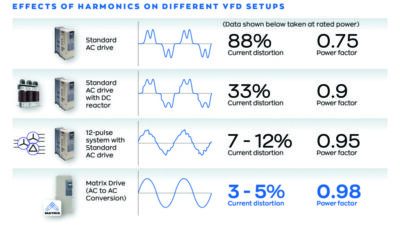

Choosing a motor of the appropriate size, or connecting a variable speed drive (VSD), to a motor will ensure it is consuming only the necessary energy to power their equipment. VSDs enable motors to be run at a partial load more efficiently, as they directly control a motor’s speed and torque – the motor can be controlled to match demand, resulting in high energy efficiency even at different speeds.

Invest for long-term gains

It is also important to consider the age and condition of motors within a production facility. Older motors may have been rewound numerous times within their lifecycle. While motors can be rewound to their original efficiency levels, in many cases this is not achieved. Older motors that require rewinding may also be less energy efficient than the latest models. All new electric motors in the EU and the UK must now meet stringent energy efficiency regulations, depending on motor type and application. For example, as of July 2021 all new three-phase motors, the kind typically used in many food and drink applications, were required to meet IE3 standards.

It can often be the case that choosing to rewind a motor, rather than purchase a new one, offers a short-term cost benefit, but will result in significantly more in the long run due to higher energy consumption. In fact, the energy cost to run an electric motor over 10 years is at least 30 times the original purchase price, meaning new, energy efficient motors may quickly provide a return on the initial investment.

Replacing oversized aging motors with new, correctly sized ones in line with IE3 or IE4 efficiency standards, represents significant energy savings, particularly when used in combination with a VSD. But, how can facility managers know when existing motors need replacing?

The retrofitting of smart sensors to existing motors will give plant managers access to real-time, continuous data on motor performance. These sensors can monitor parameters such as vibration or temperature and so can alert engineers to any deviation from optimal performance, which can help indicate when a motor might need to be replaced.

By implementing strategies to gain additional insight into motor efficiency, ensuring motors are the right size for the application, and replacing aging models with new energy efficient motors, manufacturers should be able to achieve significant energy savings. A more efficient plant brings with it improved profit margins, increased resilience and agility, and enhanced environmental credentials. With benefits such as these, taking steps to improve energy performance should be an obvious choice.

– This originally appeared on Control Engineering Europe. Edited by CFE Media and Technology.