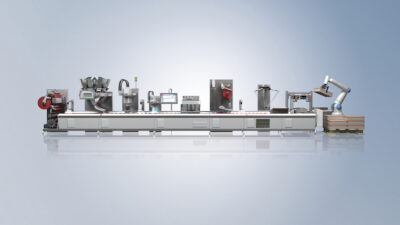

Motion control: The Universal Rack Roller Pinion System from Nexen provides high positional accuracy for medium-load motion control applications. This is a Control Engineering 2012 Engineers’ Choice finalist.

Nexen’s Roller Pinion System delivers high-accuracy linear positioning with zero backlash and simple installation. The new Universal Rack model provides an ideal solution for customers that require the advanced features of the RPS system with thrust ratings up to 750 N to 10,500 N. Differing from a traditional rack-and-pinion system, the RPS features a unique roller pinion/toothed rack combination. The pinion is comprised of bearing-supported rollers that engage a unique tooth profile. Each tooth profile is precisely measured to ensure high positional accuracy and eliminate cumulative error. As a result, the Universal Rack model delivers high positional accuracy to ± 50 m (± 0.002 in), and an innovative meshing action results in less than 5 m (± 0.0002 in) of backlash. Featuring durable alloy steel construction and/or corrosive-resistant stainless steel, Nexen’s Universal Rack outperforms traditional positioning systems in many applications including machine tool, gantry systems, automated assembly machine, and aerospace.

www.nexengroup.com

Nexen Group Inc.

Return to the list of the 2012 Engineers’ Choice finalists.