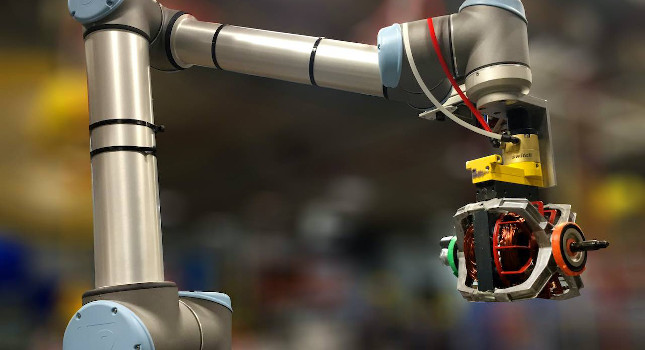

Cover Story: The ideal robotic gripper should be flexible for multiple applications and easy to use. Manufacturers should also choose robotic grippers that can help with their long-term data needs.

From 2014 through today, industrial robot sales have nearly doubled worldwide according to the International Federation of Robotics (IFR). Many of these industrial robots include an end-of-arm-tool (EOAT) for gripping.

There are two broad classes of grippers – those that grasp and those that attach. Mechanical grippers grasp while vacuum-suction-cup and magnetic grippers use air pressure or magnetism, respectively, to temporarily attach the workpiece to the EOAT. Mechanical grippers are driven by electrics or pneumatics and are designed to grasp various parts having similar shapes and sizes.

Two new classes of electric- or pneumatically-driven grippers are adaptive, which can conform to different shapes; and soft, which can be used with fragile products such as fruits, vegetables and other foods.

Regardless of class, though, there are five qualities to look for in a robotic gripper. The ideal gripper should be:

1. Easy to integrate with the robot

The ideal gripper will integrate with the hardware and software of the robot. This is one of the reasons robotics manufacturers now offer pre-integrated gripper programs. They want to lower engineering overhead and decrease time to market for their customers: original equipment manufacturers (OEMs) and end-users.

2. Easy to teach

An intuitive human-machine interface (HMI) that makes it easy to teach the gripper its functions is an ideal quality. One of the main advantages of robotics is the technology’s flexibility. If it is difficult and time-consuming to configure a new motion and then keep looking for a better gripper.

3. Flexible

Shorter product lifecycles indicate the gripper will not be gripping the same things in the same way for long. In the collaborative sphere, it is mandatory that one gripper be able to grasp or attach to as many different items as possible. A high level of flexibility is often better than less in operations with frequent product changeovers. This is true for attachment and mechanical as well as adaptive and soft grippers. Flexibility is the reason why so many research and development projects involve grippers that work like the human hand.

4. At least as good as an application-specific gripper

Robots have been deployed in so many unusual applications that many application specific grippers have been produced. Do a bit of research and determine if an unusual handling problem has already been solved with an optimized gripper. If so, see if the gripper meets the above-mentioned ideals of being easy to integrate and teach as well as flexible.

5. Supports the operation’s long-term data integration goals

For operations moving toward IIoT and Industry 4.0, grippers that provide operational data have an edge over those that do not.

Michael Guelker, product manager – Cylinders and Grippers, Festo. Edited by Chris Vavra, associate editor, Control Engineering, CFE Media and Technology, [email protected].

MORE ANSWERS

Keywords: robotics, robot grippers

There are many different types of robotic grippers for specific applications.

Regardless of type, a robotic gripper should be flexible and easy to use and integrate.

Robotic grippers should also support long-term data integration goals.

Consider this

Which of the five features is most important to you when choosing a robotic gripper?