Control Engineering International: With increasing labor costs and labor employment adjustments, China’s manufacturing industry is losing the advantage of low-cost labor to Southeast Asian countries. Increased use of industrial robots lowers production costs and frees workers from tedious labor so they can move into positions of higher technical and management skills, said Control Engineering China.

With the increasing labor cost and labor employment adjustment, China’s manufacturing industry is losing the advantage of low-cost labor and to Southeast Asian countries whose labor cost is lower. Recently Ma Xiaohe, sub decanal of the Academy of Macroeconomic Research, NDRC, said that the era of driving domestic economic growth by large export has ended. Urbanization and new industrialization will be the next engines of economic growth. Chinese manufacturing needs move to high-end stratification and reduce low-end production.

In fact China’s manufacturing industry is upgrading its production lines to deal with increasing domestic labor costs. Replacing personnel with industrial robots is one the most effective ways to do this. It lowers overall production costs and frees workers from tedious physical labor so they can move up to positions that require higher technical and management skills.

Moving production to countries with lower-cost labor isn’t the only way to reduce enterprise costs. For example, it has been reported that to lower production costs, Japanese Canon, which insists on domestic manufacturing, plans to automate all of its production lines and will find new positions for the workers on those lines. For the U.S., recent competitive manufacturing enhancements have included highly productive automatic production lines.

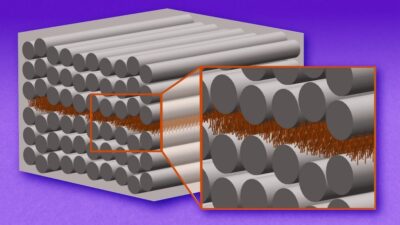

When it comes to replacing personnel with robots in production lines, there is no doubt that China has the late-mover advantage. The “eyes” of traditional robots are mainly industrial sensors, such as pressure sensors and position sensors, and thus they can only execute predefined instructions within a strictly restricted environment without sensing and reacting to the environment, which limits robotic applications. Now so-called intelligent robots can achieve effective motion control using machine vision and need not be instructed or offline programmed for their motion path, which saves a lot of programming effort and boosts productivity and product quality.

As machine vision technology is refined, it will eliminate the additional requirements of distinguishing characteristics and lighting. Sorting robots, for example, have huge applications potential in food, beverage, and packaging industries. For sorting middle- and small-sized objects, they have obvious advantages over humans, considering efficiency and cost, as they can sort quickly and inexhaustibly. It is said that the main components and modules of such robots are easily available in the marketplace. As long as the manufacturers have core control programming technologies, their robots can do sorting work. Although sorting precision may not be very high, the available precision is fine for many industries. Thus, some domestic enterprises enter into this area and roll out their own brands of robots, and the robot prices range widely, targeting different requirements.

The Chinese industrial market for intellectual robots serving production lines will be huge. Cooperative integration, synchronized integration, and vision-guided motion control are the important technical areas involved.

– This appeared in Control Engineering China www.cechina.cn and was translated for the Control Engineering North American print and digital edition. Edited by Mark T. Hoske, content manager, CFE Media, Control Engineering and Plant Engineering, [email protected].

Additional robotic vision articles below.

– Vision-guided robots automate oil tool assembly

– 415 Parts Seen: Machine Vision Guides Robot