An improved safety culture, advocated at the business level with engineering input, can bring about faster implementation of proven machine safety technologies, improving safety and adding economic value.

Sometimes, when new life rushes onto the factory floor via machine safety technology innovation, we have a “ta-dah” moment of realization about organizational effectiveness or the lack thereof!

There has been a very interesting discussion playing out on the LinkedIn Safety Automation Forum regarding safety cultures. This discussion was kicked off by Steve Ludwig (Rockwell Automation) and his highlighting of an article written by Cynthia Carroll, CEO of Anglo American plc, titled “The CEO of Anglo American on Getting Serious About Safety.” The discussion and article are, in my mind, centered around two very distinctive organizational camps I have witnessed in industry over the past 40-plus years. Those two camps are what I call “business talk” and “engineering talk.” And, most often it’s the business talk group which runs a company, establishes company vision, lays out the short and long term goals and objectives, and establishes the industrial safety policy. In other words, the business talk group follows top-down methodologies for running the business.

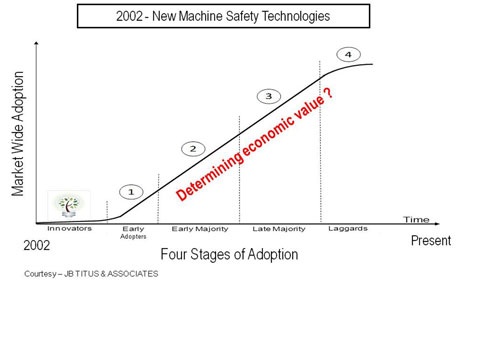

The engineering talk group is that part of the business that provides solutions and methodologies that implement the business talk. Engineering talk seldom sets or influences the setting of safety policy via bottom up approaches. However, they are the group usually most interested in innovative new ways to meet the corporate requirements established by the business talk within a company. With this said, it’s my opinion that the engineering talk camp generally will not engage in corporate wide adoption of innovative new safety technology by themselves. The engineering talk group is almost always the early adopter of new safety solutions but, as this graph illustrates, approximately 85% of the marketplace waits for company wide adoption before moving ahead. So, what’s the answer to facilitating earlier adoption?

The answer, in my opinion, is that a company’s business case for innovative new safety technology needs to be integrated with the business talk of a company. Only then do the executives of a company become aware of a paradigm shift in machine safety that improves productivity, reduces unplanned downtime and offers additional profits to the bottom line.

A recent Aberdeen Group study of more than 120 executives revealed that when executives understand that innovative new machine safety solutions are available offering opportunities for increased profitability – corporate strategies and safety policy begin to shift.

A positive shift in safety policy occurs when I have witnessed a company’s “effective safety culture” in action, moving to company wide adoption of the new safety technology.

There are lots of opinions on this subject but it’s been my experience that truly effective safety cultures roost at the top. Johnson & Johnson is one of these companies emphasizing employee safety in the Johnson & Johnson Corporate Credo.

Your comments or suggestion are always welcome, so please let us know your thoughts. Submit your ideas, experiences, and challenges on this subject in the comments section below. Click on the following text if you don’t see a comments box, then scroll down: Machine Safety: Where do effective safety cultures roost?

Related articles:

Designing In Machine Guarding

How To Integrate Safety

Safety Automation Forum

The CEO of Anglo American on Getting Serious About Safety

Contact: www.jbtitus.com for “Solutions for Machine Safety”.