Digitalization with smarter automation and instrumentation is helping with sustainability as the energy industry faces a transition and new challenges.

Learning Objectives

- Instrumentation, controls, digitalization help Shell with sustainability efforts.

- Open process automation will advance optimization, sustainability, ability to attract younger engineers.

- The 2023 ARC Industry Forum, in Orlando, Feb. 6-9, featuring discussions about digitalization helps optimize operations, helps with energy efficiency, workforce shortages, supply chain, climate change and cybersecurity.

2023 ARC Industry Forum keynote insights

- Instrumentation, controls and digitalization are helping Shell with sustainability efforts, as are increased investments in controls and instrumentation, expected to include open process automation.

- Investing in controls upgrades and sustainability helps reduce Shell’s carbon footprint and increases its ability to attract younger engineers.

- The 2023 ARC Industry Forum, in Orlando, Feb. 6-9, includes discussions about digitalization, optimization of operations, energy efficiency, workforce shortages, supply chain, climate change and cybersecurity.

The energy industry is in transition, and Allen Pertuit, Shell vice president of downstream projects, with 35 years in industry, said digitalization, automation and instrumentation investments are helping. He was among keynote speakers at the ARC Advisory Group’s 2023 ARC Industry Forum, Feb. 6-9, in Orlando, and online Feb. 27-March 27.

This year’s forum, according to Peter Manos, director of research, ARC Advisory Group, has more than 860 attendees, 200 speakers, 250 companies, and 70 workshops in 4 days. Andy Chatha, ARC president, in welcoming attendees noted education, sharing best practices and relationship building are endemic to the forum.

Petrochemical leader began in instrumentation and controls

Pertuit began at Shell as a field engineer in instrumentation and controls, was an asset manager for upstream and downstream and worked for a process control company.

The petroleum industry is transforming quickly. He noted major oil companies have diversified. Shell’s diversifying portfolio includes chemical, biofuels, renewables, carbon capture and storage (CCS) and hydrogen facilities, as well as natural gas and new feedstock plants.

Shell sustainability efforts include digitalization, automation upgrades

Shell, like many industrial companies, has committed to reduce emissions and is targeting net zero carbon emissions by 2050.

A renewable natural gas plant extracts gas from the waste produced from 30,000 cows, with digesters the size of mid-sized stadiums, giving leftovers back to farmers for fertilizer. A converted refinery creates diesel fuel from waste vegetable oil. Carbon capture and storage technologies are the last resort, he said, to other sustainability efforts, but also are being pursued.

Stepping up sustainability with automation, controls, instrumentation upgrades

Technologies applied to measure and optimize facilities help sustainability efforts also can improve safety and improve revenue by predicting failures.

Facility startup and shutdown is most dangerous, and value-added automation technologies help with sustainability efforts. The oil and gas industry has moved more slowly, and Shell has been trying to push things a bit faster.

Shell has remote video communications to connect to 345 oil platforms. COVID-19 in 2020 sent everyone in technology support home. This forced the company to get more comfortable with using intrinsically safe tablet computers and operating more remotely.

No question about the need for open process automation

As far as interoperability standards efforts go, “Why is open process automation even a question?” he asked, because those doing new upgrade projects are not patient bunch. New energy plants are smaller facilities, perhaps $100 million have smaller margins, and have a greater need for automation and instrumentation to leverage profits more quickly.

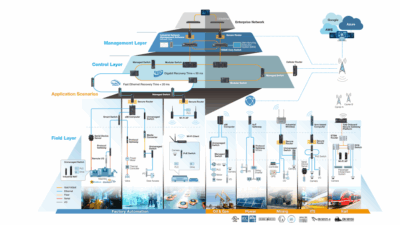

The energy industry is in transition (see image). Autonomous operations require leading technology and some courage.

Open process automation (OPA) also is on the radar of top leadership; a member of Shell’s board of directors talked about digitalization efforts.

Modern controls technologies help attract young engineering talent

Automation and digitalization can serve company goals and help Shell stay competitive, Pertuit said. Aligning data standards help with safe and secure data transfer. People and skills are changing. Digitalization and open process automation efforts are helping to attract the best and brightest people out of universities. It also helps when Shell discusses its expanding role in renewables.

Change is not easy, but necessary, Pertuit noted, as the world aims to produce more clean energy. Shell’s strategy includes getting to net zero profitably and safely.

Coverage from ARC Industry Forum

Control Engineering will post related coverage on the 2023 ARC Industry Forum meeting as it is available. Articles from prior ARC Industry Forums include automation and controls digitalization, interoperability, sustainability and interoperability:

Factories born digital save 10x conversion cost

Digitalization, interoperability help with industrial sustainability

Building interoperable control systems

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: ARC Industry Forum, ARC Advisory Group, digital transformation

CONSIDER THIS

How is digitalization and smarter automation and controls helping with your sustainability efforts?

ONLINE