Advancing material technologies for printed hybrid electronics are highlighted for engineers.

Scientists at the U.S. Department of Energy’s Argonne National Laboratory are advancing material technologies for printed hybrid electronics. Four details for engineers are highlighted.

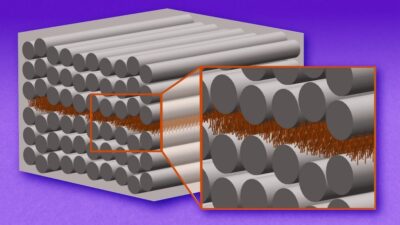

- Printed hybrid electronics combine modular components with printed circuitry on thin, flexible material. They are helping to create next-generation lightweight sensors, phones, wearables, radio frequency antennae and flexible displays.

- Engineers create these electronics using various printing technologies. This tends to waste less material, reduce costs and help manufacturers create prototypes more quickly compared to standard methods.

- Manufacturers face material challenges for printed hybrid electronics. They need high-performance conductive, semiconductive, and dielectric ink materials that are compatible between each other and also are printable and durable.

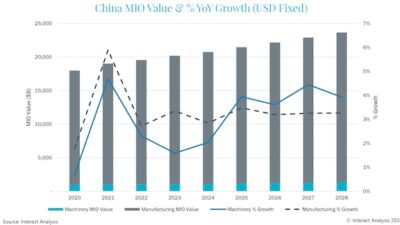

- Despite these challenges, the global market for printed electronics rose 22% at a compound annual growth rate (CAGR) over the past five years. This trend could continue due to the strong demand in mobile, flexible, and sensor devices spurred by the fifth generation (5G) of communication technology.

Argonne has more information on the topic. See a recent webinar here.

Yuepeng Zhang is a principal materials scientist at Argonne National Laboratory. Edited by Chris Vavra, web content manager, Control Engineering, CFE Media, [email protected].