Researchers at North Carolina State University have developed software to enable people using robotic prosthetics or exoskeletons to walk in a safer, more natural manner on different types of terrain.

North Carolina State University researchers have developed new software that can be integrated with existing hardware to enable people using robotic prosthetics or exoskeletons to walk in a safer, more natural manner on different types of terrain. The new framework incorporates computer vision into prosthetic leg control, and includes robust artificial intelligence (AI) algorithms that allow the software to better account for uncertainty.

“Lower-limb robotic prosthetics need to execute different behaviors based on the terrain users are walking on,” said Edgar Lobaton, co-author of a paper on the work and an associate professor of electrical and computer engineering at North Carolina State University. “The framework we’ve created allows the AI in robotic prostheses to predict the type of terrain users will be stepping on, quantify the uncertainties associated with that prediction, and then incorporate that uncertainty into its decision-making.”

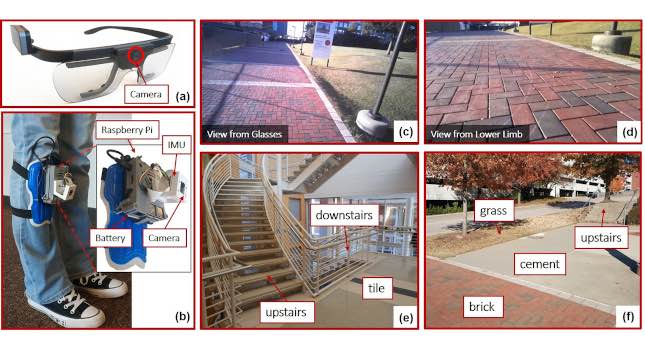

The researchers focused on distinguishing between six different terrains that require adjustments in a robotic prosthetic’s behavior: tile, brick, concrete, grass, “upstairs” and “downstairs.”

“If the degree of uncertainty is too high, the AI isn’t forced to make a questionable decision – it could instead notify the user that it doesn’t have enough confidence in its prediction to act, or it could default to a ‘safe’ mode,” said Boxuan Zhong, lead author of the paper and a recent Ph.D. graduate from NC State.

The “environmental context” framework incorporates both hardware and software elements. The researchers designed the framework for use with any lower-limb robotic exoskeleton or robotic prosthetic device, but with one additional piece of hardware: a camera. In their study, the researchers used cameras worn on eyeglasses and cameras mounted on the lower-limb prosthesis itself. The researchers evaluated how the AI was able to make use of computer vision data from both types of camera, separately and when used together.

“Incorporating computer vision into control software for wearable robotics is an exciting new area of research,” said Helen Huang, a co-author of the paper. “We found that using both cameras worked well, but required a great deal of computing power and may be cost prohibitive. However, we also found that using only the camera mounted on the lower limb worked pretty well – particularly for near-term predictions, such as what the terrain would be like for the next step or two.”

Huang is the Jackson Family Distinguished Professor of Biomedical Engineering in the Joint Department of Biomedical Engineering at NC State and the University of North Carolina at Chapel Hill.

The most significant advance, however, is to the AI itself.

“We came up with a better way to teach deep-learning systems how to evaluate and quantify uncertainty in a way that allows the system to incorporate uncertainty into its decision making,” Lobaton said. “This is certainly relevant for robotic prosthetics, but our work here could be applied to any type of deep-learning system.”

To train the AI system, researchers connected the cameras to able-bodied individuals, who then walked through a variety of indoor and outdoor environments. The researchers then did a proof-of-concept evaluation by having a person with lower-limb amputation wear the cameras while traversing the same environments.

“We found that the model can be appropriately transferred so the system can operate with subjects from different populations,” Lobaton said. “That means that the AI worked well even thought it was trained by one group of people and used by somebody different.”

However, the new framework has not yet been tested in a robotic device.

“We are excited to incorporate the framework into the control system for working robotic prosthetics – that’s the next step,” Huang said.

“And we’re also planning to work on ways to make the system more efficient, in terms of requiring less visual data input and less data processing,” Zhong said.

– Edited by Chris Vavra, associate editor, Control Engineering, CFE Media, [email protected]. See more Control Engineering robotics stories.