Georgia Tech and Northwestern University researchers have built a robot entirely from smaller robots known as “smarticles” to unlock the principles of a potentially new locomotion technique.

Building conventional robots typically requires carefully combining components like motors, batteries, actuators, body segments, legs and wheels. Researchers from the Georgia Institute of Technology and Northwestern University with support from the Army Research Office and the National Science Foundation, have taken a new approach, building a robot entirely from smaller robots known as “smarticles” to unlock the principles of a potentially new locomotion technique.

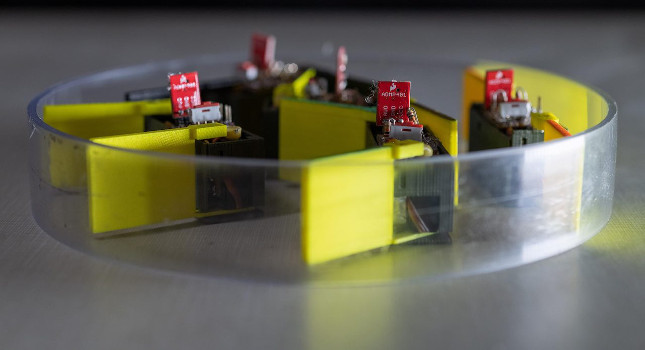

The 3-D-printed smarticles — short for smart active particles — can do one thing: flap their two arms. But when five of these smarticles are confined in a circle, they begin to nudge one another, forming a robophysical system known as a “supersmarticle” that can move by itself. Adding a light or sound sensor allows the supersmarticle to move in response to the stimulus — and even be controlled well enough to navigate a maze.

Though rudimentary now, the notion of making robots from smaller robots — and taking advantage of the group capabilities that arise by combining individuals — could provide mechanically based control over very small robots. Ultimately, the emergent behavior of the group could provide a new locomotion and control approach for small robots that could potentially change shapes.

“These are very rudimentary robots whose behavior is dominated by mechanics and the laws of physics,” said Dan Goldman, a Dunn Family Professor in the School of Physics at the Georgia Institute of Technology. “We are not looking to put sophisticated control, sensing, and computation on them all. As robots become smaller and smaller, we’ll have to use mechanics and physics principles to control them because they won’t have the level of computation and sensing we would need for conventional control.”

The foundation for the research came from an unlikely source: a study of construction staples. By pouring these heavy-duty staples into a container with removable sides, former Ph.D. student Nick Gravish — now a faculty member at the University of California San Diego — created structures that would stand by themselves after the container’s walls were removed.

Shaking the staple towers eventually caused them to collapse, but the observations led to a realization that simple entangling of mechanical objects could create structures with capabilities well beyond those of the individual components.

“A robot made of other rudimentary robots became the vision,” Goldman said. “You could imagine making a robot in which you would tweak its geometric parameters a bit and what emerges is qualitatively new behaviors.”

Light hitting a smarticle (smart active particle) causes it to stop moving, while the other smarticles continue to flap their arms. The resulting interactions produce movement toward the stopped smarticle, providing control that doesn’t depend on computer algorithms. Courtesy: Rob Felt, Georgia Tech[/caption]

The project is of interest to the U.S. Army because it could lead to new robotic systems capable of changing their shapes, modalities and functions, said Sam Stanton. He is program manager of complex dynamics and systems at the Army Research Office, an element of U.S. Army Combat Capabilities Development Command’s Army Research Laboratory.

“Future Army unmanned systems and networks of systems are imagined to be capable of transforming their shape, modality, and function. For example, a robotic swarm may someday be capable of moving to a river and then autonomously forming a structure to span the gap,” Stanton said. “Dan Goldman’s research is identifying physical principles that may prove essential for engineering emergent behavior in future robot collectives as well as new understanding of fundamental tradeoffs in system performance, responsiveness, uncertainty, resiliency, and adaptivity.”

– Edited by Chris Vavra, production editor, Control Engineering, CFE Media, [email protected].