Modern edge devices put emphasis on cybersecurity, data democratization and programmability to enable advanced cloud capabilities.

Learning Objectives

- Evaluate technologies and requirements for industrial edge and cloud capabilities, including the continuous coordination of industrial cybersecurity.

- Contrast costs of industrial cloud capabilities versus on-premise provisioning and consider clarity of industrial cloud and edge data.

- Examine industrial edge device resilience amid cloud reliability concerns with refined integration for edge and cloud technologies.

Industrial edge architecture and cybersecurity insights

- Technologies and requirements for industrial edge and cloud capabilities include the continuous coordination of industrial cybersecurity.

- When deciding between cloud or on-premise industrial architectures, contrast costs of industrial cloud capabilities versus on-premise provisioning and consider clarity of industrial cloud and edge data.

- Refined integration for edge and cloud technologies can help with industrial edge device resilience and cloud reliability concerns.

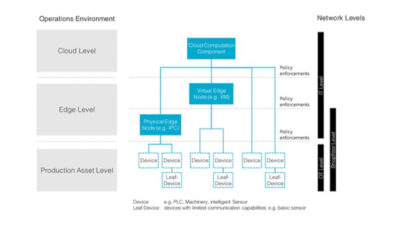

In an era where digital transformation dictates the pace of business innovation, understanding the synergy between edge devices and cloud technology is more than a necessity. It is a strategic imperative. The landscape of data management and processing is undergoing a radical change, marked by the emergence of sophisticated edge devices and seemingly infinite storage and computing power in the cloud.

Industrial journey from edge to cloud

However, when it comes to moving critical production and infrastructure data to the cloud, a number of concerns arise; cybersecurity is paramount among them. Add the recurring costs of cloud storage and software tools to fears surrounding network reliability, and it’s easy to understand the hesitancy to select a cloud-based architecture for mission-critical operations. Even putting those considerations to the side, there’s still the issue of contextualizing the enormous swaths of data that cloud servers are capable of storing.

Fear not. New technologies embedded in modern edge devices are transforming the industrial internet of things (IIoT) landscape by enabling secure and seamless data transmission to the cloud. This advancement allows for more than just data collection; it ensures that data is transmitted safely and efficiently, ready for analysis in cloud-based systems. These capabilities are vital in an increasingly connected world, where the quick and secure handling of data is essential for timely and informed decision-making across various industries.

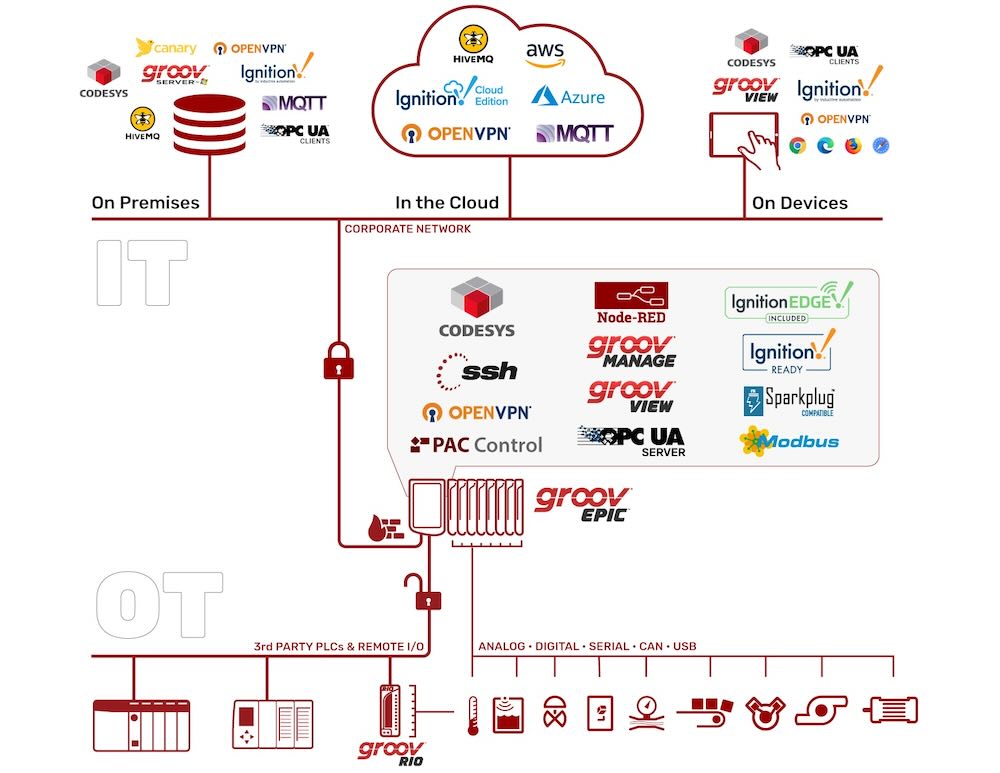

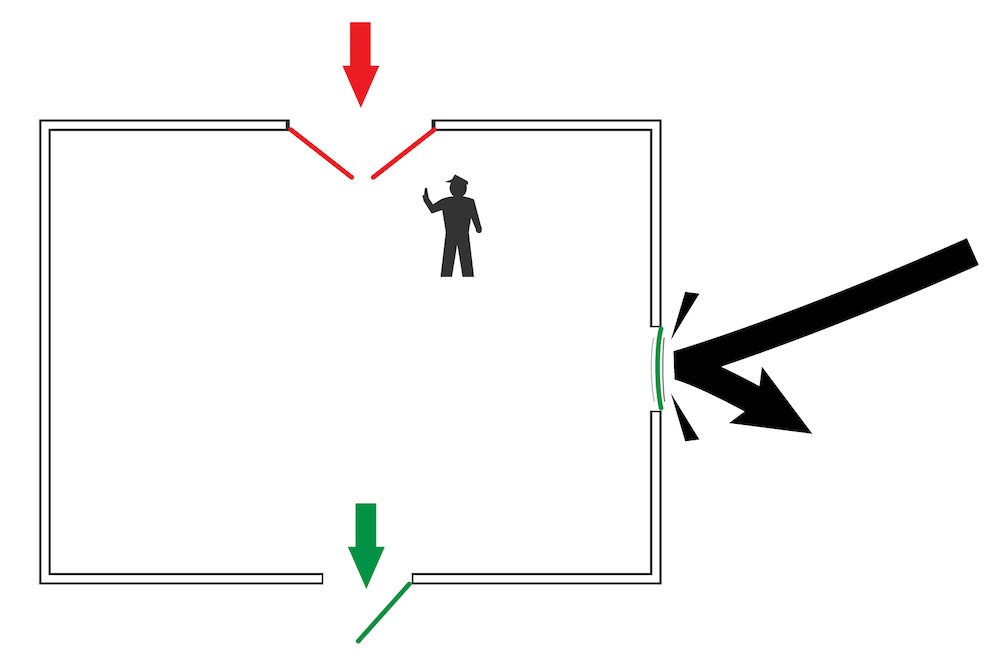

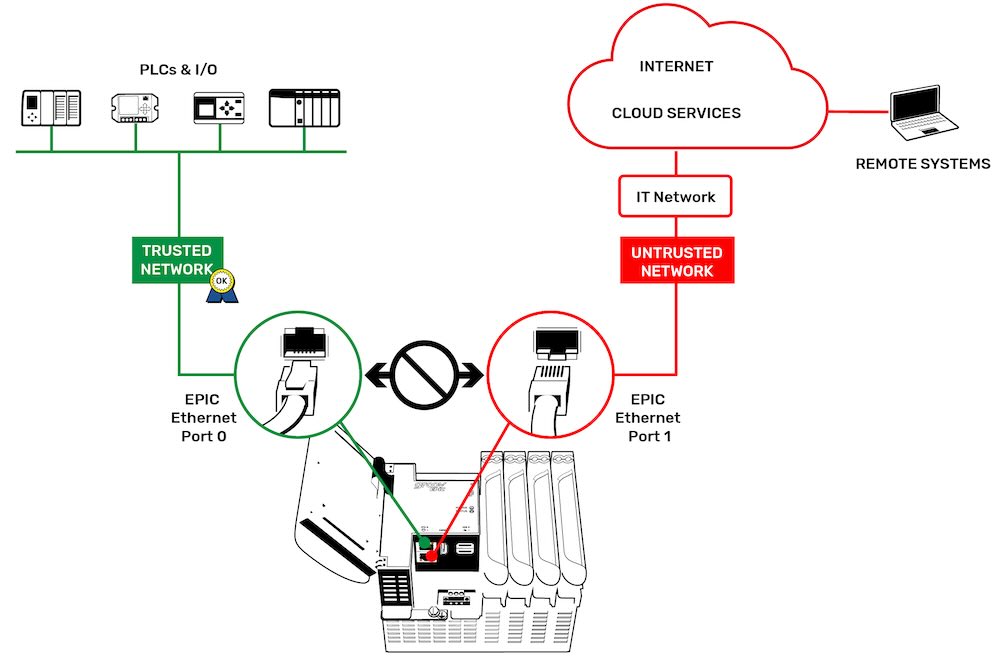

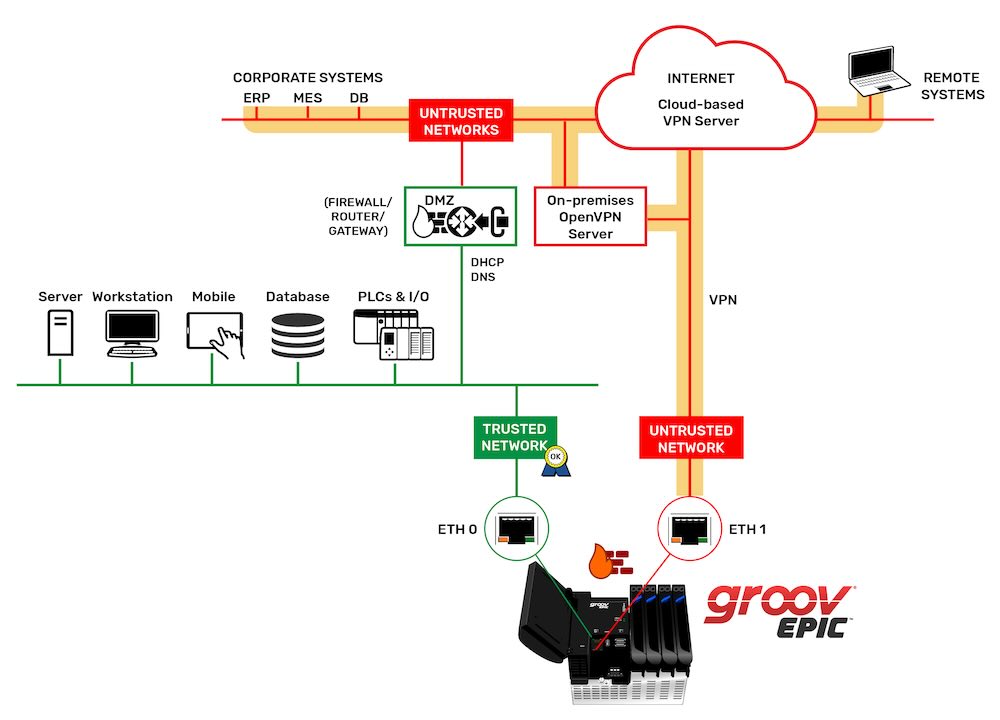

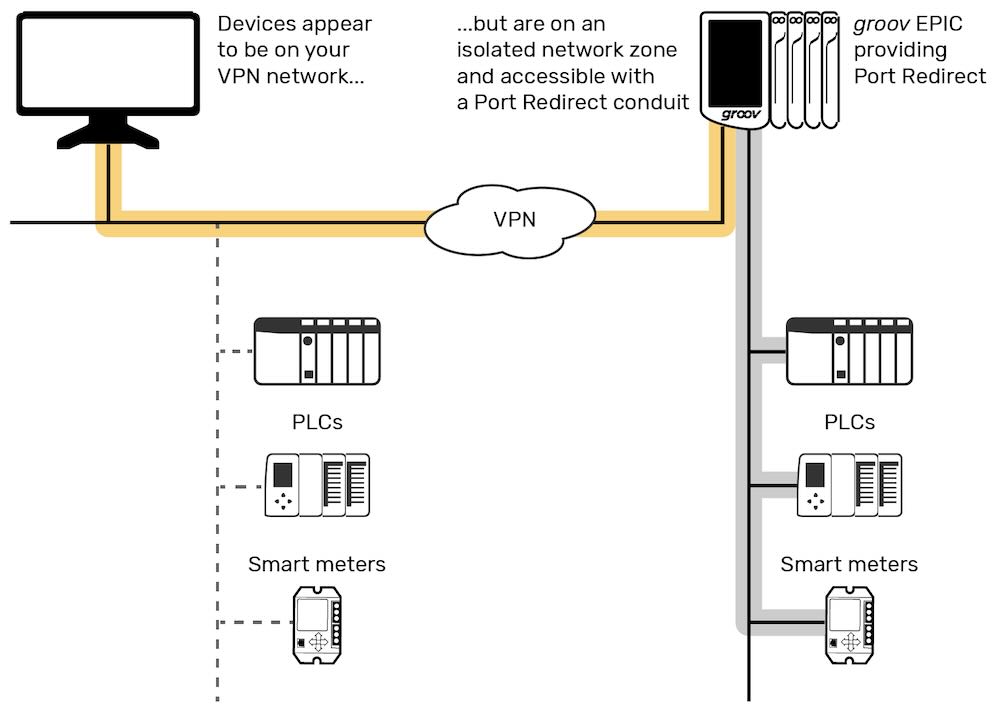

Industrial cybersecurity: A continuous coordination

Traditionally, edge devices like input/output (I/O) systems and programmable logic controllers (PLCs) were the most vulnerable links in network security. These devices, critical in industrial settings, lacked advanced cybersecurity features, making them easy targets for cyber threats. In stark contrast, modern edge devices are designed with astrong emphasis on cybersecurity. They come equipped with a range of protective features like firewalls, secure socket link/transport layer security (SSL/TLS) encryption, virtual private network (VPN) clients, secure authentication, network zoning capabilities and regular updates to guard against evolving threats. This shift marks a significant advancement in securing industrial networks, transforming edge devices from weak points into fortified gateways inthe digital ecosystem.

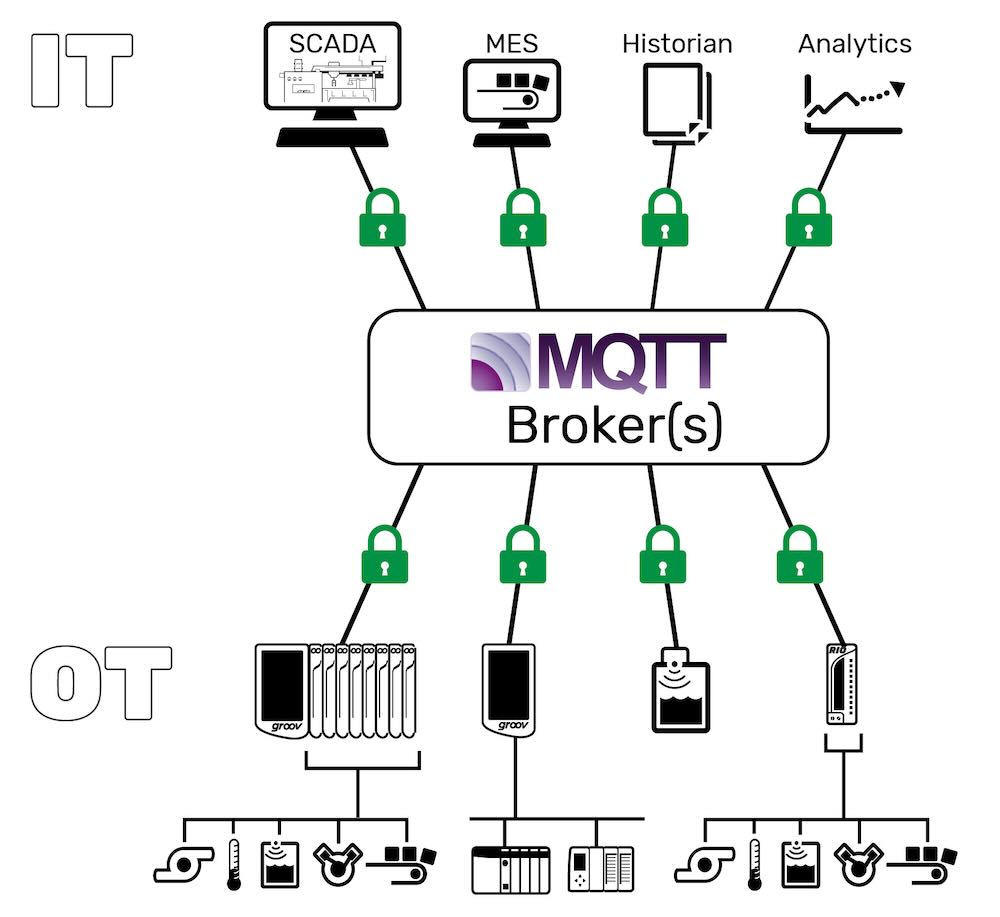

Alongside the existing cybersecurity features of modern edge devices, the implementation of outbound communication protocols like message queuing telemetry transport (MQTT) adds another layer of security. These protocols facilitate device-originated communication, which inherently reduces vulnerability to external threats. By allowing edge devices to securely initiate and control data exchange, MQTT minimizes the need for open inbound network ports, thus significantly decreasing the risk of cyber-attacks. This proactive approach in data communication reinforces the security framework of industrial networks, further transforming edge devices into robust, secure gateways in the digital infrastructure.

Costs contrasted: Industrial cloud capabilities versus on-premise provisioning

On-premise industrial server solutions come with significant initial capital costs. This includes the expense of purchasing server racks, servers, cooling equipment, software packages and IT administration tools. Beyond these upfront investments, there are also substantial ongoing maintenance costs, encompassing hardware repairs, software updates and energy consumption for operation and cooling systems.

In contrast, cloud-based storage and computing services typically operate on an annual subscription model. While this might seem costly at first glance, it often proves more economical in the long run. The cloud service provider handles much of the management and maintenance, from server upkeep to software updates. This reduces the direct costs associated with physical infrastructure and shifts the burden of ongoing maintenance away from the user. This shift can lead to significant savings in time and resources, allowing businesses to focus on core activities rather than IT management.

An additional advantage of cloud-based storage is its scalability. Starting with a small virtual setup at a minimal cost, scaling up as needed is remarkably easier and cost-effective compared to on-premise solutions. With cloud services, increasing storage or computational power doesn’t require physical hardware additions, but a simple adjustment in the service plan, offering flexibility and efficiency in resource management. This scalability feature makes cloud solutions not only economical but also adaptable to evolving business needs.

Context clarity: Coordinating industrial cloud and edge data

Transferring data from edge devices to the cloud can initially seem chaotic, but modern data modeling tools like user-defined types (UDTs) and advanced data models provide a solution. These tools ensure that by the time data reaches the cloud, it’s already contextualized. This means data is not just raw numbers; it’s processed and tagged with relevant context (like location, device type and operational status), making it immediately useful and comprehensible. This preprocessing at the edge simplifies cloud data management and analysis, turning potential confusion into clear, actionable insights.

Industrial edge device resilience amid cloud reliability concerns

Reliability concerns, especially during network outages, often shadow cloud computing. Yet, the advanced capabilities of edge devices provide a robust solution. With multi-core processors, varied control and programming options and built-in human-machine interfaces (HMIs), these devices ensure local operations continue smoothly, even when cloud connectivity falters.

Edge devices stand out for their autonomous operation. They handle critical functions and data processing independently, including local data storage and buffering, proving essential when cloud services are interrupted. This autonomy is key to maintaining uninterrupted operations, ensuring that essential systems remain operational and efficient.

While edge devices offer local resilience, cloud computing elevates capabilities with advanced analytics, artificial intelligence (AI), machine learning (ML), anomaly detection (AD) and large language models (LLMs). This synergy between edge autonomy and cloud-based intelligence creates a balanced digital infrastructure, effectively addressing cloud reliability challenges while harnessing its advanced analytical potential.

Refined integration of edge and cloud technologies

In the exploration of edge-to-cloud architectures, there’s an intricate balance between the localized robustness of edge devices and the expansive capabilities of cloud computing. This synergy is shaping a more efficient and secure future for data management and processing in various industries.

Edge devices have evolved significantly, now embodying secure and autonomous units capable of sophisticated local processing. Their enhanced cybersecurity features and ability to operate independently are pivotal in maintaining operational integrity, even in the absence of cloud connectivity. This local control is crucial in industrial settings, where even brief downtimes can have significant impacts.

On the other hand, the cloud offers advanced computational power and storage capacity, making it an invaluable resource for large-scale data analysis. With capabilities like AI, ML, AD and LLMs, the cloud extends beyond mere data storage, providing deep insights and analytics that are transforming decision-making processes in businesses.

The convergence of edge and cloud technologies represents not just an advancement in individual capabilities, but a collaborative force. This integration allows for a more resilient and adaptable digital infrastructure, where local and cloud systems complement each other, ensuring immediate operational efficiency and long-term analytical depth.

As industrial customers progress, this balanced interplay between edge and cloud computing is poised to become a fundamental element in the digital transformation narrative of numerous industries. Grasping and harnessing this synergy is crucial for unlocking unprecedented levels of innovation, security, and operational efficiency in the rapidly changing digital world.

Dan White is director of technical marketing at Opto 22. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Edge computing, industrial cloud, edge to cloud architectures

CONSIDER THIS

Have you considered new edge and cloud technologies in light of cybersecurity and data requirements?

ONLINE