Robots are helping change and transform the manufacturing industry and helping companies realize their potential in an Industry 4.0 world.

Robotics insights

- Robotics evolution spans from ancient mythology to modern Industry 4.0, augmenting efficiency, safety, and flexibility in manufacturing processes.

- The future of manufacturing hinges on adaptive systems where humans and robots collaborate autonomously, reimagining traditional processes for efficiency.

From the evolution of collaborative robots to the integration of Industry 4.0 technologies, the rise of mobile robots and the challenges and opportunities posed by low volume, high mix production we explore the cutting edge of innovation.

Mark Noschang, applications engineering manager for robotic solutions, at Omron, described what the future of robotics looks like in his presentation “The Future of Robot Manufacturing: Emerging Trends and Innovation,” at Omron Open 2023 in Hoffman Estates, Ill.

He first outlined how the idea of robotics go as far back as Ancient Greece in mythology and, in real-world terms, the 1700s with automatons, which were a base model of what people come to expect.

An industrial robot, Noschang said, is defined by ISO 8373 as an automatically controlled, reprogrammable, multipurpose manipulator that is programmable in three or more axes. A mobile robot, by contrast, is able to travel under its own control.

“Robots can do so much,” he said. “We have the ability to automate the task in the facility to increase speed, efficiency and productivity. Robots are handling the dangerous tasks people can’t do safely.”

They’re also handling the repetitive, redundant tasks humans don’t want to do. Mobile robots, in particular, can transport heavy or cumbersome items from point A to point B in a facility, saving humans the constant wear and tear.

Trends in the robotic industry

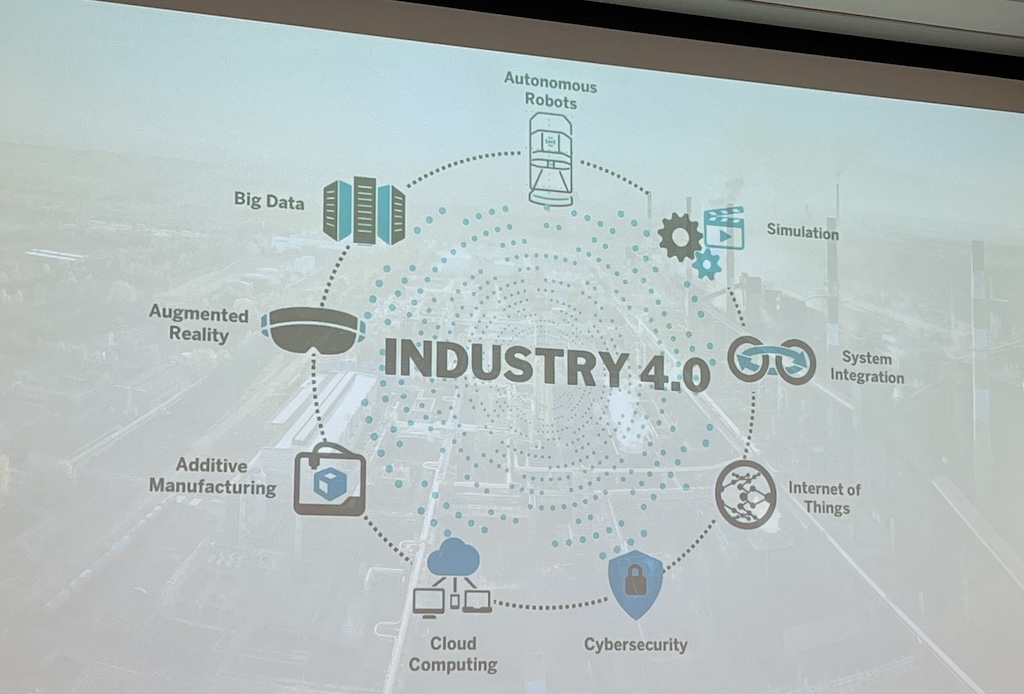

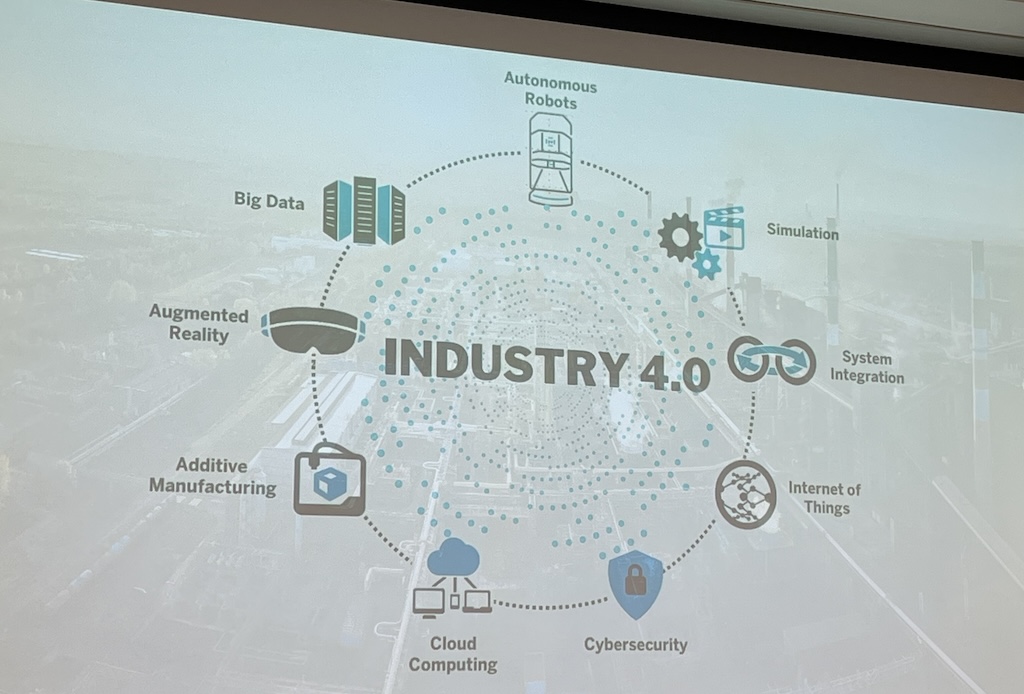

Much has been made of Industry 4.0, or the Fourth Industrial Revolution, which is the rise of cyber-physical systems and expanding on how electronics and information technology (IT) were used to further automate production. Industry 4.0 includes autonomous robots, system integration, cybersecurity, cloud computing and more. All these technologies are being brought together to help make manufacturing better and more automated.

However, another trend, Industry 3.5, is sandwiched between the two and has had a marked effect on manufacturing. The idea of “Having it your way” as coined by Burger King is also being reflected in manufacturing, Noschang said.

“Manufacturing is going in that direction and the manufacturing systems are going along and they need to be flexible.”

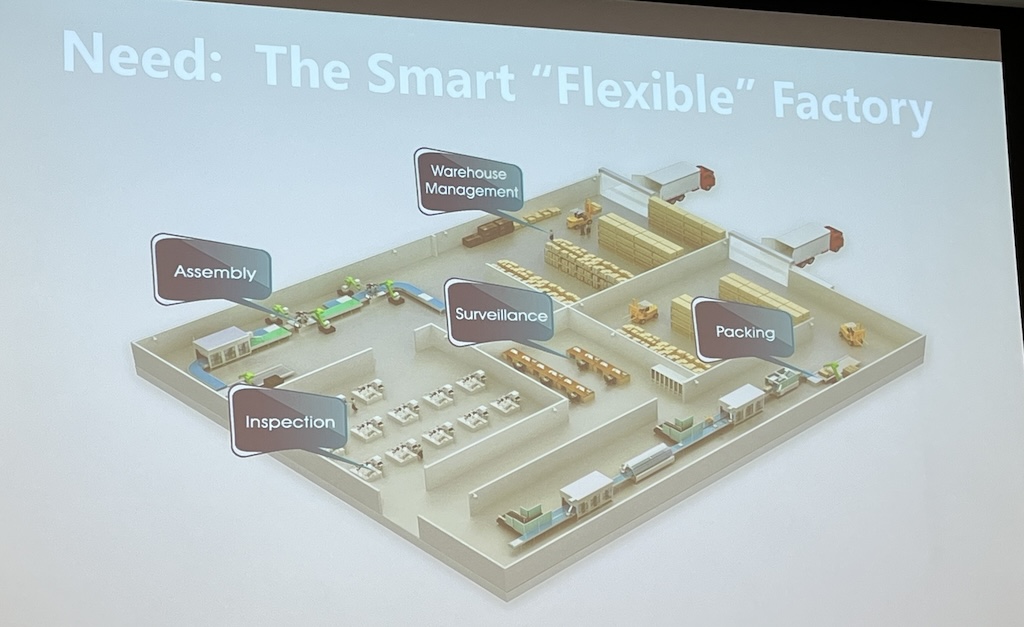

The smart factory of the future, he said, needs to be flexible and can cater to needs that might change at any given moment. Assembly, inspection, warehouse management, surveillance and packing systems all need to be in sync with one another and adjust to the changing climate of the day. That’s even more important now, Noschang said, given the labor shortages that are only growing.

Developing a collaborative and adaptive workplace

Manufacturing has been moving from one extreme to another. For the longest time, it was a manual production process. Automation has been a major driving force as technology has improved and taken some of the load off humans. However, with technologies such as collaborative robots, Noschang believes manufacturing is reaching a point where humans and machines are going to reach a point where they are working in an autonomous and collaborative environment.

“We need to reimagine some of these processes,” he said. “By thinking through systems and automation, there may be a better way to redeploy what is already there.”

Chris Vavra, web content manager, CFE Media and Technology, [email protected].