To mitigate harmonics 18-pulse and active-front-end (AFE) drive technologies can be used; know strengths and weaknesses for various industrial drives applications. Energy efficiency also is a consideration.

Learning Objectives

- Understand primary applications for 18-pulse drive technology and active front end (AFE) drive technology and how they combat harmonics.

- Learn about some trade-offs between 18-pulse drives and AFE drives.

- Explore AFE drives and 18-pulse drives misconceptions and their future?

Industrial harmonics troubleshooting insights

- For industrial drives, 18-pulse drive technology and active-front-end (AFE) drive technology can be applied in different ways to combat harmonics and improve power quality.

- Trade-offs exist between 18-pulse drives and AFE drives for industrial applications, to reduce industrial harmonics.

- Misconceptions may exist around AFE drives and 18-pulse drives; what’s the future for each of these industrial drive technologies?

This industrial drives and harmonics question-and-answer article explores two ways to mitigate harmonics and enhance control in various applications. Answering questions are Rob Fenton, Eaton’s customer excellence senior manager, and Austen Scudder, product line manager, drives, soft starters, and assemblies for Eaton’s Industrial Control Division.

Question: What’s the difference between 18-pulse drive technology and active-front-end (AFE) drive technology?

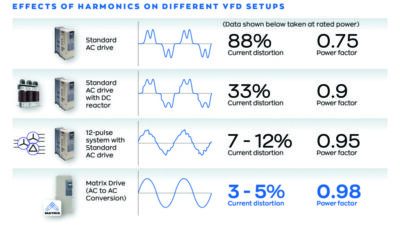

Answer: Both industrial drive solutions aim to mitigate harmonics, but they do it differently. An 18-pulse drive uses a phase shifting transformer to create nine phases that cancel out harmonics, achieving a low harmonic rating. An AFE consists of an inductor-capacitor-inductor (LCL) filter to reduce switching noise and two inverters that actively manage harmonics by switching power back and forth between the line and the direct-current (DC) bus.

Question: What are the primary applications for 18-pulse drives?

Answer: The 18-pulse drives are a common solution for mitigating harmonics in applications. We commonly see 18-pulse drives in the heating, ventilation and air conditioning (HVAC) market where there’s a lot of harmonic accumulation. Another area is water and wastewater applications, where high power and energy consumption can lead to harmonic accumulation and potential system issues. While there are other industrial drive applications, these two most frequent areas and where the benefits tend to be very strong.

Question: Where are AFE drives most used?

Answer: AFE drives find applications in various industries beyond harmonic mitigation. They’re used in industrial settings, energy recovery systems and environments with unbalanced power conditions. AFE drives are versatile and can be employed in HVAC and water and wastewater applications as well.

Question: Can you explain some trade-offs between these technologies?

Answer: Several factors influence the choice between 18-pulse drives and AFE drives. AFE drives have a smaller footprint in lower power ranges, making them suitable for applications up to around 200 horsepower. In terms of power conditioning, AFEs can compensate for unbalanced power systems. On the other hand, 18-pulse drives excel in harsh conditions and provide better isolation from surges and line distortions; 18-pulse drives also tend to have a longer lifespan due to lower voltage ripple on the DC bus.

Questions: What are some misconceptions about AFE drives?

Answer: One common misconception is that AFE drives outperform 18-pulse drives at lower load conditions due to percentage-based comparisons. However, the total harmonic current matters more than the percentage, and AFE drives can still exceed limits at lower loads. It’s important to understand the actual harmonic content in different scenarios.

Question: What misconceptions exist about 18-pulse drives?

Answer: One misconception is about the efficiency of 18-pulse drives due to the transformer. Modern 18-pulse transformers are efficient auto transformers. Modern 18-pulse drives use auto transformers, which are much more efficient than isolation transformers. In many cases, 18-pulse drives are more energy efficient than AFE drives because of the number of inverter-based power conversions. An AFE typically has two inverter-based power conversion stages and an LCL filter. In comparison, an 18-pulse drive has an 18-pulse auto transformer and only one inverter-based power conversion stage.

Question: What’s the future for 18-pulse drives and AFE drives?

Answer: Both 18-pulse and AFE drives have growth potential. As industrial drives markets focus on energy efficiency, both technologies will evolve to meet the demands of various applications. Engineers should consider the specific needs of their applications to choose the right solution. The future holds exciting advancements in power semiconductors and circuit boards, leading to smaller and more efficient AFE drives. The rapid pace of technological development is creating a dynamic environment for these industrial drive technologies.

Rob Fenton is Eaton’s customer excellence senior manager; Austen Scudder is product line manager, drives, soft starters, and assemblies for Eaton’s Industrial Control Division. Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, [email protected].

KEYWORDS: Harmonic mitigation, 18-pulse drives, AFE drives

CONSIDER THIS

Are you applying the right kind of drive technology to mitigate harmonics in industrial applications?

ONLINE